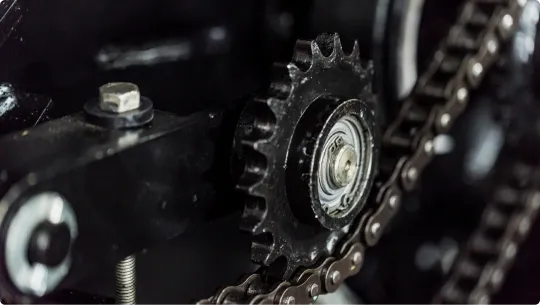

QD Sprocket No.100-3 Triple Type

Roller Chain Sprockets: Overview, Types, and Applications

Roller chain sprockets are an essential component of power transmission systems. These sprockets are designed to work in conjunction with roller chains to provide efficient and reliable power transfer in various industrial applications. Roller chain sprockets come in a variety of types, sizes, and materials to meet the specific needs of different applications.

History and Development of Roller Chain Sprockets

The development of roller chain sprockets can be traced back to the industrial revolution in the 19th century. The invention of the roller chain and sprocket system revolutionized power transmission in factories and other industrial settings. Since then, roller chain sprockets have undergone significant improvements in terms of design, materials, and manufacturing processes to meet the ever-increasing demands of modern industries.

Types of Roller Chain Sprockets

Roller chain sprockets can be classified based on their tooth profile, number of teeth, pitch diameter, bore size, and material. The most common types of roller chain sprockets include:

- Standard Sprockets: These sprockets have a standard tooth profile and are widely used in general-purpose applications.

- Taper-Lock Sprockets: These sprockets feature a tapered bore and are designed for easy installation and removal.

- QD Sprockets: These sprockets feature a quick-detachable bushing that allows for easy installation and removal without the need for additional machining or tools.

- Double-Single Sprockets: These sprockets have both single and double-strand chains on the same sprocket.

- Idler Sprockets: These sprockets are used to take up slack in the chain and maintain tension.

Advantages of Roller Chain Sprockets

Roller chain sprockets offer several advantages over other types of power transmission systems, including:

- High Efficiency: Roller chain sprockets provide efficient power transfer with minimal energy loss.

- High Load Capacity: Roller chain sprockets can withstand heavy loads and provide reliable performance in demanding applications.

- Low Maintenance: Roller chain sprockets require minimal maintenance, reducing downtime and associated costs.

- Wide Compatibility: Roller chain sprockets are compatible with various types of chains and other power transmission components, providing flexibility and interchangeability.

- Long Service Life: Roller chain sprockets are designed to provide long service life with proper installation, maintenance, and usage.

Applications of Roller Chain Sprockets

Roller chain sprockets are widely used in various applications such as:

- Conveyors

- Machinery

- Agricultural equipment

- Automotive industry

- Printing industry

- Textile industry

- Food processing industry

- Construction equipment

Materials Used for Roller Chain Sprockets

Roller chain sprockets can be made from a variety of materials, including:

- Steel: Carbon steel, alloy steel, and stainless steel are common materials used for roller chain sprockets due to their high strength and durability.

- Plastics: Certain types of plastics such as nylon and acetal are used for roller chain sprockets in applications where corrosion resistance and low noise are desired.

- Cast Iron: Cast iron sprockets are used in applications where high strength and wear resistance are required.

- Aluminum: Aluminum sprockets are lightweight and corrosion-resistant, making them suitable for certain applications such as food processing and packaging machinery.

Installation, Maintenance, and Repair of Roller Chain Sprockets

Proper installation, maintenance, and repair are crucial for the optimal performance and longevity of roller chain sprockets. Here are some tips for installing, maintaining, and repairing roller chain sprockets:

Installation

- Clean the shaft and sprocket surfaces to ensure a proper fit.

- Align the sprocket with the shaft and slide it onto the shaft.

- Tighten the screws or bolts to secure the sprocket onto the shaft.

- Ensure that the sprocket is firmly attached to the shaft.

Maintenance

- Regularly inspect the sprocket for wear, damage, and proper alignment.

- Lubricate the sprocket teeth to reduce wear and noise.

- Tighten the set screws or bolts to maintain proper tension.

- Replace worn or damaged sprockets promptly to avoid further damage to the chain and other components.

Repair and Replacement

If a roller chain sprocket is damaged or worn beyond repair, it should be replaced promptly to avoid further damage to the chain and other components. When replacing a sprocket, follow the same installation procedures as outlined above.

Questions and Answers

- Q: What is a roller chain sprocket?

- Q: What are the advantages of roller chain sprockets?

- Q: What are the common types of roller chain sprockets?

- Q: What materials are used to make roller chain sprockets?

- Q: What maintenance is required for roller chain sprockets?

A: A roller chain sprocket is a type of power transmission component that works in conjunction with a roller chain to transfer power between rotating shafts.

A: Roller chain sprockets offer several advantages, including high efficiency, high load capacity, low maintenance, wide compatibility, and long service life.

A: The common types of roller chain sprockets include standard sprockets, taper-lock sprockets, QD sprockets, double-single sprockets, and idler sprockets.

A: Roller chain sprockets can be made from materials such as steel, plastics, cast iron, and aluminum.

A: Roller chain sprockets require regular inspection for wear, lubrication of the sprocket teeth, and proper tightening of set screws or bolts.

About Our Company

Our company specializes in supplying various industrial plastic gears, including agricultural gearboxes, power output shafts, sprockets, hydraulic couplings, worm gear reducers, gear racks, removable chains, pulleys and pulleys, planetary gearboxes, timing pulleys, bushings, and more. We offer high-quality products at competitive prices and provide thoughtful services to our customers. We welcome customers to contact us for customized orders based on their specific needs and requirements.

Author: lmc

Disclaimer: All content on this page is for reference only. Our products are accessories rather than original spare parts. We are not the holder of the original trademark of the content. Our products are only suitable for aftermarket accessories rather than original spare parts. Our accessories can perfectly fit the original spare parts. If you need to purchase original spare parts, please contact the original factory to purchase.

About us

We guarantee top-quality products at the best prices in China! Special orders are welcome, and if you’re interested in any of our products, feel free to reach out for more detailed information. We ensure our products are safe, high-quality, and reasonably priced. Please contact us as soon as possible if you’d like to learn more. We’re eager to cooperate with you!

A large portion of our products is exported to Europe and the Americas, with both standard and custom options available. We can manufacture according to your drawings or samples, using standard materials or as per your specific requirements. Choosing us means choosing reliability.

Materials Available

1. Stainless Steel: SS201, SS303, SS304, SS316, SS416, SS420

2. Steel:C45(K1045), C46(K1046),C20

3. Brass:C36000 ( C26800), C37700 ( HPb59), C38500( HPb58), C27200(CuZn37), C28000(CuZn40)

4. Bronze: C51000, C52100, C54400, etc

5. Iron: 1213, 12L14,1215

6. Aluminum: Al6061, Al6063

7.OEM according to your request

Surface Treatment

Annealing, natural canonization, heat treatment, polishing, nickel plating, chrome plating, zinc plating,yellow passivization, gold passivization, satin, Black surface painted etc.

Processing Method

CNC machining, punch,turning, milling, drilling, grinding, broaching, welding and assembly

QC & Certificate

Technicians self-check in production,final-check before package by professional Quality inspector

ISO9001:2008 , ISO14001:2001,ISO/TS 16949:2009

Package & Lead Time

Size: Drawings

Wooden Case/Container and pallet, or as per customized specifications.

15-25days samples. 30-45days offcial order

Port: Shanghai/Ningbo port

Industries We Service