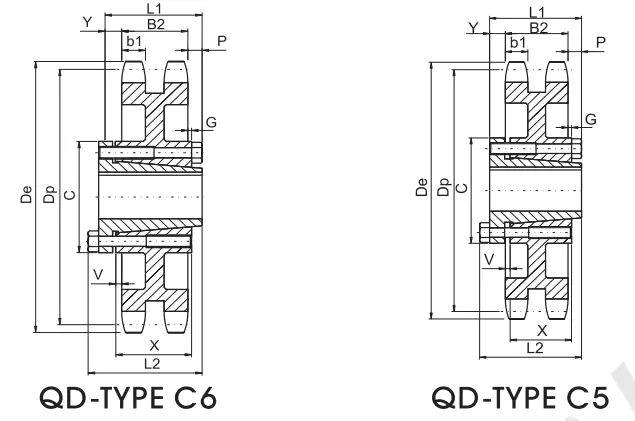

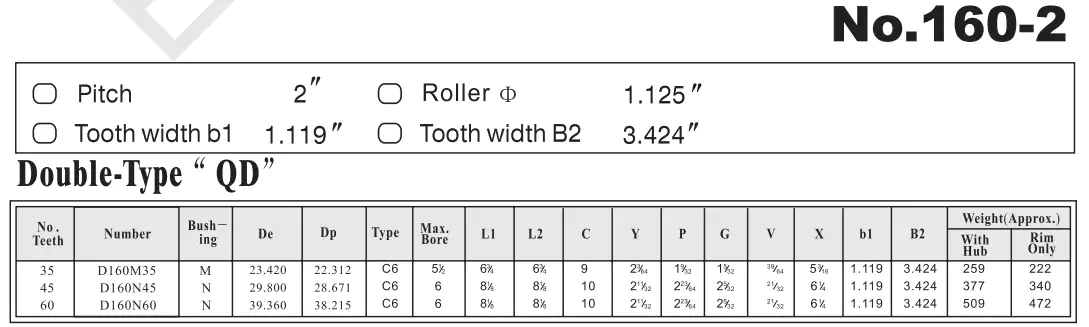

QD Sprocket No.160-2 Double Type

Introduction

QD Sprocket No.160-2 Double Type is a type of sprocket used in power transmission systems. It is designed to efficiently transfer power between a driving shaft and a driven shaft. The QD sprocket is an essential component in various industrial applications.

Usage Scenarios

QD Sprocket No.160-2 Double Type finds wide applications in industries such as manufacturing, agriculture, and construction. Some common usage scenarios include:

- Conveyor Systems: The QD sprocket is used to transfer power between conveyor belts, facilitating the movement of goods and materials.

- Industrial Machinery: It is employed in various types of machinery, such as packaging machines, processing equipment, and industrial ovens.

- Agricultural Equipment: QD sprockets are utilized in machinery like combine harvesters, tractors, and seeders for efficient power transmission.

- Construction Machinery: The sprocket is essential in construction equipment like excavators, cranes, and bulldozers, enabling smooth operation and power transfer.

Product History and Classification

QD Sprocket No.160-2 Double Type has a rich history, evolving from traditional chain sprockets to the innovative quick-detachable (QD) design. It falls under the category of roller chain sprockets, specifically the double type. The double type sprocket features two sets of teeth or cogs, providing enhanced power transfer capabilities.

Advantages of QD Sprocket No.160-2 Double Type

- High Durability: The sprocket is constructed using quality materials and undergoes rigorous manufacturing processes, ensuring excellent durability and long service life.

- Efficient Power Transmission: With its precision-engineered teeth, the QD sprocket enables efficient and reliable power transfer, minimizing energy loss.

- Easy Installation and Maintenance: The QD bushing design allows for quick installation and removal, reducing downtime and maintenance efforts.

- Wide Compatibility: QD Sprocket No.160-2 Double Type is available in various sizes and configurations, making it compatible with different shaft dimensions and chain specifications.

- Cost-Effective Solution: The combination of its durability and low maintenance requirements leads to reduced operational costs over time.

Materials and Installation

QD Sprocket No.160-2 Double Type is commonly manufactured using high-quality steel alloys, providing the necessary strength and resilience. The installation process involves the following steps:

- Prepare the required tools and materials for the installation.

- Clean the surfaces of the shaft and sprocket to ensure proper attachment.

- Position the sprocket accurately on the shaft.

- Securely install the QD bushing into the hub of the sprocket.

- Fasten the sprocket in place using the appropriate fastening method.

- Inspect the installation for any misalignment or issues.

Maintenance, Repair, and Replacement

To ensure optimal performance and longevity of the QD Sprocket No.160-2 Double Type, regular maintenance and timely repair are essential. Follow these guidelines:

- Regularly inspect the sprocket for signs of wear, such as worn-out teeth or damage.

- Properly lubricate the sprocket and chain to minimize friction and maximize efficiency.

- Replace any worn-out components promptly to prevent further damage to the sprocket or other machinery parts.

- If replacement is necessary, follow the installation steps mentioned earlier to ensure proper attachment.

Company's Other Product Businesses

At our company, we specialize in supplying various industrial plastic gears and components. Our product range includes agricultural gearboxes, power output shafts, hydraulic couplings, worm gear reducers, gear racks, removable chains, pulleys and pulleys, planetary gearboxes, timing pulleys, and bushings. We offer high-quality products at competitive prices, accompanied by excellent customer service.

Frequently Asked Questions (FAQ)

-

Q: How do I choose the right QD sprocket size for my application?

A: Selecting the appropriate QD sprocket size depends on factors such as power requirements, shaft dimensions, and chain specifications. We recommend consulting our guidelines or seeking professional advice to ensure proper sizing. -

Q: Can I reuse the QD bushing after removing the sprocket?

A: Yes, QD bushings are designed for reuse. However, it is important to inspect the bushing for any signs of wear or damage before reinstalling. -

Q: What maintenance is required for QD sprockets?

A: QD sprockets generally require minimal maintenance. It is recommended to regularly inspect for wear, properly lubricate, and promptly replace any worn-out components for optimal performance. -

Q: Can the QD sprocket be used in corrosive environments?

A: Yes, QD sprockets can be used in corrosive environments. However, it is advisable to apply proper surface treatment or coating to enhance their corrosion resistance. -

Q: Can I install a QD sprocket without a QD bushing?

A: No, the QD bushing is an integral part of the QD sprocket assembly. It provides the necessary grip and secure attachment to the shaft.

Author: lmc

Disclaimer: The content of this page is sourced from the internet and is provided as a reference for product selection. Our products are accessories rather than original spare parts, and we are not the holder of the original trademark. Our accessories can perfectly fit the original spare parts. If you need to purchase original spare parts, please contact the original factory.

About us

We guarantee top-quality products at the best prices in China! Special orders are welcome, and if you’re interested in any of our products, feel free to reach out for more detailed information. We ensure our products are safe, high-quality, and reasonably priced. Please contact us as soon as possible if you’d like to learn more. We’re eager to cooperate with you!

A large portion of our products is exported to Europe and the Americas, with both standard and custom options available. We can manufacture according to your drawings or samples, using standard materials or as per your specific requirements. Choosing us means choosing reliability.

Materials Available

1. Stainless Steel: SS201, SS303, SS304, SS316, SS416, SS420

2. Steel:C45(K1045), C46(K1046),C20

3. Brass:C36000 ( C26800), C37700 ( HPb59), C38500( HPb58), C27200(CuZn37), C28000(CuZn40)

4. Bronze: C51000, C52100, C54400, etc

5. Iron: 1213, 12L14,1215

6. Aluminum: Al6061, Al6063

7.OEM according to your request

Surface Treatment

Annealing, natural canonization, heat treatment, polishing, nickel plating, chrome plating, zinc plating,yellow passivization, gold passivization, satin, Black surface painted etc.

Processing Method

CNC machining, punch,turning, milling, drilling, grinding, broaching, welding and assembly

QC & Certificate

Technicians self-check in production,final-check before package by professional Quality inspector

ISO9001:2008 , ISO14001:2001,ISO/TS 16949:2009

Package & Lead Time

Size: Drawings

Wooden Case/Container and pallet, or as per customized specifications.

15-25days samples. 30-45days offcial order

Port: Shanghai/Ningbo port

Industries We Service