Cast Iron Chain F801 Crate Conveyor Chain CC Class

Rivetless Drop-Forged Cast Chain: A Versatile and Durable Conveyor Chain

The Rivetless Drop-Forged Cast Chain is a versatile conveyor chain that is commonly used in various industries, such as automotive, steel, and food processing. This chain is designed to transport heavy loads, such as large crates, pallets, and other bulky objects, over long distances. It is made of high-quality materials, such as carbon steel or stainless steel, which makes it durable, corrosion-resistant, and wear-resistant.

History and Classification of the Rivetless Drop-Forged Cast Chain

The Rivetless Drop-Forged Cast Chain was introduced in the early 20th century and has since undergone several improvements to meet the changing needs of different industries. Today, there are various types of Rivetless Drop-Forged Cast Chains available in the market, including hollow pin chains, leaf chains, flat top chains, side bow chains, and many others. Each type has specific features that make it suitable for different applications.

Advantages of the Rivetless Drop-Forged Cast Chain

The Rivetless Drop-Forged Cast Chain has several advantages over other types of conveyor chains, making it a popular choice for many industrial applications. Some of the key advantages include:

- High Load Capacity: The Rivetless Drop-Forged Cast Chain is designed to handle heavy loads, making it ideal for applications that require the transport of large and heavy objects.

- Durability: This type of chain is made from high-strength materials, such as carbon steel or stainless steel, which makes it highly resistant to wear, corrosion, and damage from impacts.

- Low Maintenance: The Rivetless Drop-Forged Cast Chain requires minimal maintenance, reducing downtime and increasing productivity. It can operate over long periods without the need for lubrication or adjustment.

- Quiet Operation: The Rivetless Drop-Forged Cast Chain operates quietly, reducing noise pollution in the working environment.

- Smooth and Consistent Operation: The rollers on the Rivetless Drop-Forged Cast Chain help to ensure smooth and consistent operation, reducing the risk of product damage or loss.

- Easy to Install: The Rivetless Drop-Forged Cast Chain is easy to install and can be customized to fit various conveyor configurations.

Product Materials, Installation and Maintenance

The Rivetless Drop-Forged Cast Chain is available in various materials, such as carbon steel, stainless steel, and nickel-plated steel. The selection of material depends on the specific application and environmental conditions. The chain can be installed using standard attachment links or customized attachments, depending on the conveyor configuration.

To ensure optimal performance and longevity, regular maintenance is required. This includes lubrication, regular inspection for wear and tear, and prompt replacement of damaged or worn-out components. The chain should also be cleaned regularly to remove dirt, debris, and other contaminants that can compromise its performance.

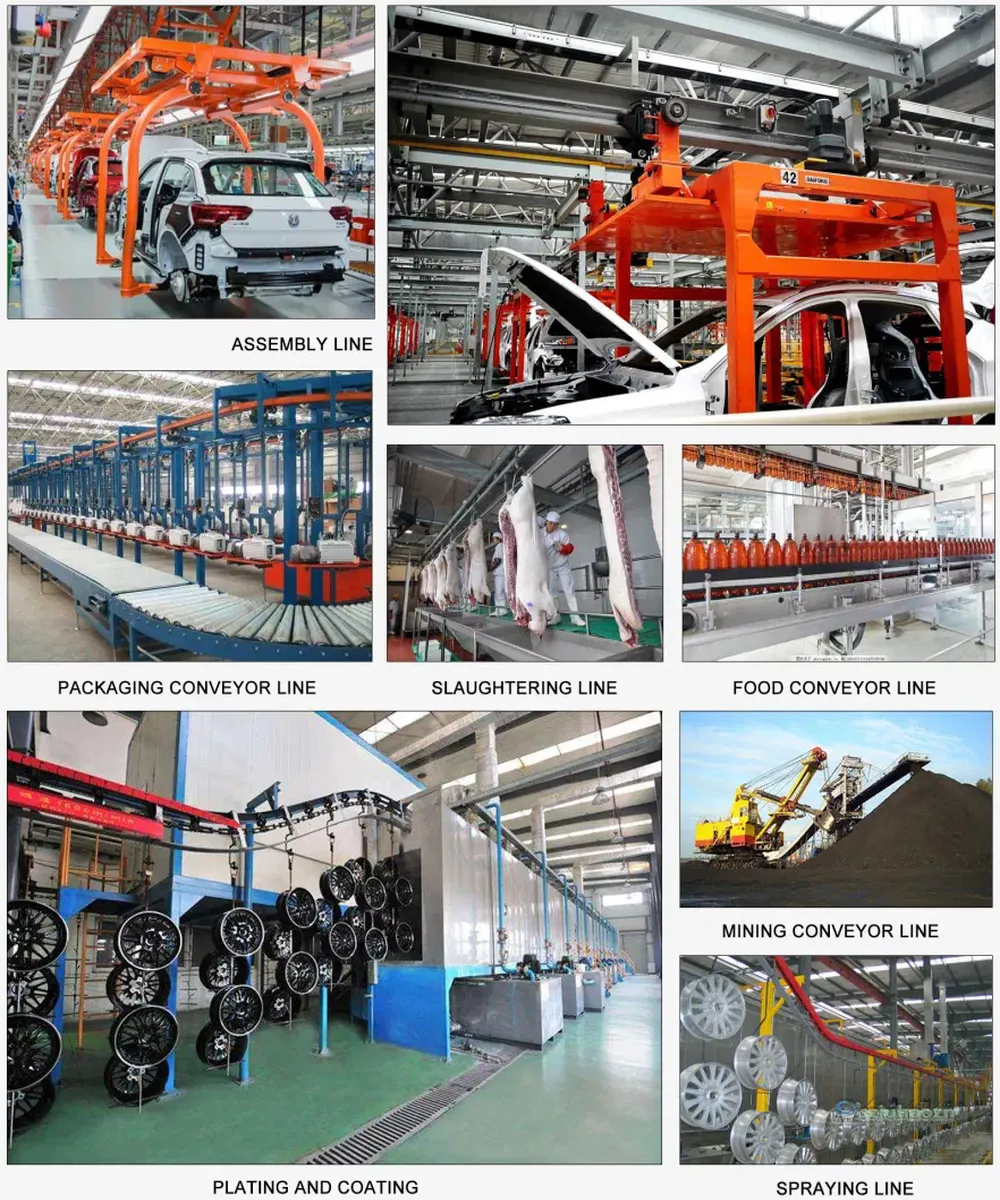

Usage Scenarios of the Rivetless Drop-Forged Cast Chain

The Rivetless Drop-Forged Cast Chain is a reliable and versatile option for a variety of conveyor applications. Some of the most common usage scenarios for this chain include:

- Automotive industry: The Rivetless Drop-Forged Cast Chain is used to transport heavy automotive components, such as engines and transmissions, in factories and warehouses.

- Steel industry: The Rivetless Drop-Forged Cast Chain is used to transport heavy steel materials, such as ingots and rolls, in steel mills and foundries.

- Food and beverage processing: The Rivetless Drop-Forged Cast Chain is used to transport crates and pallets of food and beverage products in factories and warehouses.

- Construction: The Rivetless Drop-Forged Cast Chain is used to transport heavy materials, such as concrete blocks and steel beams, on construction sites.

- Logistics: The Rivetless Drop-Forged Cast Chain is used to transport crates and pallets of goods in warehouses and distribution centers.

Other Industrial Plastic Gears Products

In addition to the Rivetless Drop-Forged Cast Chain, we specialize in various industrial plastic gears, such as agricultural gearboxes, power output shafts, sprockets, hydraulic couplings, worm gear reducers, gear racks, removable chains, pulleys and pulleys, planetary gearboxes, timing pulleys, bushings, etc. Our products are of high quality, competitively priced, and come with thoughtful customer service. We welcome customers to customize their products with pictures and samples.

Questions and Answers

1. What industries commonly use the Rivetless Drop-Forged Cast Chain?

Answer: The Rivetless Drop-Forged Cast Chain is commonly used in various industries, such as automotive, steel, and food processing.

2. What are the advantages of the Rivetless Drop-Forged Cast Chain?

Answer: The Rivetless Drop-Forged Cast Chain has several advantages, including high load capacity, durability, low maintenance, quiet operation, smooth and consistent operation, and easy installation.

3. What materials is the Rivetless Drop-Forged Cast Chain available in?

Answer: The Rivetless Drop-Forged Cast Chain is available in various materials, including carbon steel, stainless steel, and nickel-plated steel.

4. What are some common usage scenarios for the Rivetless Drop-Forged Cast Chain?

Answer: Some common usage scenarios for the Rivetless Drop-Forged Cast Chain include automotive industry, steel industry, food and beverage processing, construction, and logistics.

5. What other products does the company specialize in besides the Rivetless Drop-Forged Cast Chain?

Answer: The company specializes in various industrial plastic gears, such as agricultural gearboxes, power output shafts, sprockets, hydraulic couplings, worm gear reducers, gear racks, removable chains, pulleys and pulleys, planetary gearboxes, timing pulleys, bushings, etc.

Author: lmc

Note: All the content of this page comes from the Internet, and the content is only used as a reference for product selection. Our products are accessories rather than original spare parts; we are not the holder of the original trademark of the content. Our products are only suitable for aftermarket accessories rather than original spare parts. Our accessories can perfectly fit the original spare parts; if you need to purchase original spare parts, please contact the original factory to purchase.

About us

We guarantee top-quality products at the best prices in China! Special orders are welcome, and if you’re interested in any of our products, feel free to reach out for more detailed information. We ensure our products are safe, high-quality, and reasonably priced. Please contact us as soon as possible if you’d like to learn more. We’re eager to cooperate with you!

A large portion of our products is exported to Europe and the Americas, with both standard and custom options available. We can manufacture according to your drawings or samples, using standard materials or as per your specific requirements. Choosing us means choosing reliability.

Materials Available

1. Stainless Steel: SS201, SS303, SS304, SS316, SS416, SS420

2. Steel:C45(K1045), C46(K1046),C20

3. Brass:C36000 ( C26800), C37700 ( HPb59), C38500( HPb58), C27200(CuZn37), C28000(CuZn40)

4. Bronze: C51000, C52100, C54400, etc

5. Iron: 1213, 12L14,1215

6. Aluminum: Al6061, Al6063

7.OEM according to your request

Surface Treatment

Annealing, natural canonization, heat treatment, polishing, nickel plating, chrome plating, zinc plating,yellow passivization, gold passivization, satin, Black surface painted etc.

Processing Method

CNC machining, punch,turning, milling, drilling, grinding, broaching, welding and assembly

QC & Certificate

Technicians self-check in production,final-check before package by professional Quality inspector

ISO9001:2008 , ISO14001:2001,ISO/TS 16949:2009

Package & Lead Time

Size: Drawings

Wooden Case/Container and pallet, or as per customized specifications.

15-25days samples. 30-45days offcial order

Port: Shanghai/Ningbo port

Industries We Service