EPG70 Australian Standard Link Chain

EPG70 Australian Standard Link Chain

The EPG70 Australian Standard Link Chain is a high-quality chain that is designed to meet specific classification requirements. It comes with a test certificate to ensure its build quality, which is especially useful when selecting anchor systems. It is important to carefully check the test certificate for accuracy and correct information to ensure the chain's reliability. The manufacturer's good industry reputation can also be considered.

The working load limit of the chain depends on the manufacturer's safety factor. For example, the EPG40 chain has a safety factor of 5:1, while the EPG70 chain has a safety factor of 3:1. The EPG70 chain has high tensile strength, equivalent to a short BBB chain, but it is more expensive.

However, the EPG70 chain has a complicated galvanizing process, which can lead to hydrogen embrittlement due to the deposition of hydrogen in the steel's crystal lattice. Chain manufacturers caution against re-galvanizing EPG70 chains, although independent sources report that this issue is sporadic and only affects high-strength chains.

Our company also offers a wide variety of conveyor chain types. If you need more information about conveyor chain or other product types, you can contact us by email or communicate with our online staff. We look forward to working with you.

Benefits of Link Chain

There are several advantages to using link chains on your bike. First, link chains provide enhanced power and are easier to change compared to single chainrings. They are also lighter, making it easier to transport and adjust to different settings. Another advantage is that link chains allow for easy changes in the rear wheel position without needing to retune the bike's suspension system.

Link chains are known for their durability and cost-effectiveness. They have a long lifespan and are more affordable compared to single cufflinks. Stainless steel chains, in particular, offer great value for money. While they may get scratched easily, high-quality chains are usually scratch-resistant.

Link chains also offer flexibility in installation. They can be set up anywhere within the conveyor belt and individual links can be easily removed or replaced. They are versatile and reliable, although a twisted chain may require more attention for repair.

Chain link fencing is another common application of link chains. It is a cost-effective and easy-to-install option that can last for a long time. Many installers are familiar with chain link fencing and can perform the installation at a reasonable cost.

Related Sprockets

Properly installed sprockets can greatly improve the efficiency of a chain-driven motion system. They are essential for carrying heavy loads and ensuring the proper operation of the machine. When selecting sprockets, it is important to consider the size and type of fit for your system.

The lifespan of a sprocket can vary depending on factors such as riding style, chain pitch and size, and maintenance regime. Typically, a brand new steel sprocket has a lifespan of less than 5,000 km. To extend the sprocket's life, consider using one with hardened teeth, which can triple its longevity.

Sprockets are toothed wheels that mesh with a chain as they rotate. They are different from gears as they don't mesh directly. Sprockets are used in various applications, ranging from disposable cameras to professional bicycles, as well as in different motor vehicles.

Our Advantage

- High-quality products at competitive pricing

- Wide variety of products available in various materials and sizes

- Our products are manufactured in an ISO9001:2008 certified factory

- Great customer service to answer all your questions

- Largest online selection of power transmission products

- High-quality made-to-order products

Q & A

Q: What is the strength of your company?

A: Our company has an engineering team with experience in product and machine designs, ready to help you solve any problems you may encounter.

Q: How about the quality of your products?

A: We have our own professional factory and highly skilled workers, giving us a competitive advantage over our competitors.

Q: What is your minimum order quantity (MOQ)?

A: Our minimum order quantity is just one piece, allowing for flexible purchasing options.

Q: Can you produce customized products based on drawings or samples?

A: Yes, we have extensive experience in producing non-standard products and can accommodate custom requirements.

Q: What is the lifespan of your sprockets?

A: The lifespan of our sprockets can vary depending on factors such as riding style and conditions, chain pitch and size, and maintenance. Consider using sprockets with hardened teeth for extended longevity.

Author: lmc

Please note that all the content on this page is sourced from the internet and is only provided as a reference for product selection. Our products are accessories and not original spare parts. We are not the holder of the original trademark. Our accessories are designed to perfectly fit the original spare parts. If you need to purchase original spare parts, please contact the original factory.

About us

We guarantee top-quality products at the best prices in China! Special orders are welcome, and if you’re interested in any of our products, feel free to reach out for more detailed information. We ensure our products are safe, high-quality, and reasonably priced. Please contact us as soon as possible if you’d like to learn more. We’re eager to cooperate with you!

A large portion of our products is exported to Europe and the Americas, with both standard and custom options available. We can manufacture according to your drawings or samples, using standard materials or as per your specific requirements. Choosing us means choosing reliability.

Materials Available

1. Stainless Steel: SS201, SS303, SS304, SS316, SS416, SS420

2. Steel:C45(K1045), C46(K1046),C20

3. Brass:C36000 ( C26800), C37700 ( HPb59), C38500( HPb58), C27200(CuZn37), C28000(CuZn40)

4. Bronze: C51000, C52100, C54400, etc

5. Iron: 1213, 12L14,1215

6. Aluminum: Al6061, Al6063

7.OEM according to your request

Surface Treatment

Annealing, natural canonization, heat treatment, polishing, nickel plating, chrome plating, zinc plating,yellow passivization, gold passivization, satin, Black surface painted etc.

Processing Method

CNC machining, punch,turning, milling, drilling, grinding, broaching, welding and assembly

QC & Certificate

Technicians self-check in production,final-check before package by professional Quality inspector

ISO9001:2008 , ISO14001:2001,ISO/TS 16949:2009

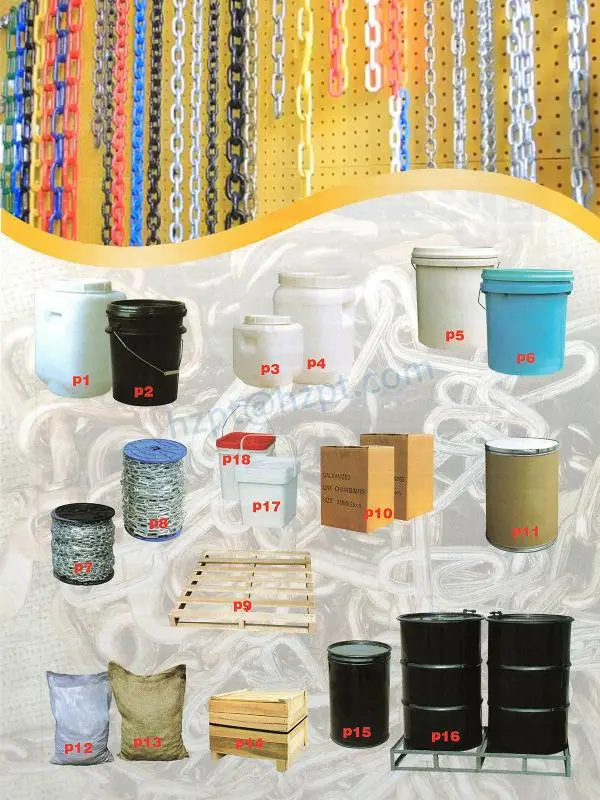

Package & Lead Time

Size: Drawings

Wooden Case/Container and pallet, or as per customized specifications.

15-25days samples. 30-45days offcial order

Port: Shanghai/Ningbo port

Industries We Service