Rotary Cutter Gearboxes – Replacement of Omni Code RC-51 Gearbox

Introducing the RC51 Rotary Cutter Gearbox, a top-tier solution crafted by Tebsa, designed to meet the rigorous demands of modern agricultural and industrial vegetation management. Engineered for rotary cutters and brush cutters, this gearbox excels in cutting through thick grass, weeds, and brush with unmatched reliability. Featuring a robust cast iron housing, heavy-duty bevel gears, and advanced sealing technology, the RC51 delivers exceptional durability and performance, making it an ideal replacement for Omni Gearbox RC-51 models.

Key Features of the RC51 Rotary Cutter Gearbox

The RC51 gearbox is built to handle high torque and horsepower from today’s tractors, ensuring seamless operation in tough conditions. Its standout features include:

- Sturdy Construction: Made with premium cast iron for long-lasting resilience.

- High-Capacity Oil Reservoir: Holds 27 oz. (0.80 L) for optimal lubrication and cooling.

- Oversized Bearings: Tapered roller and deep groove ball bearings enhance load capacity.

- Triple Lip Spring-Loaded Seals: Metal oil seals ensure leak-proof performance.

- Easy Installation & Maintenance: Bolt-on design and simple disassembly for cleaning and lubrication.

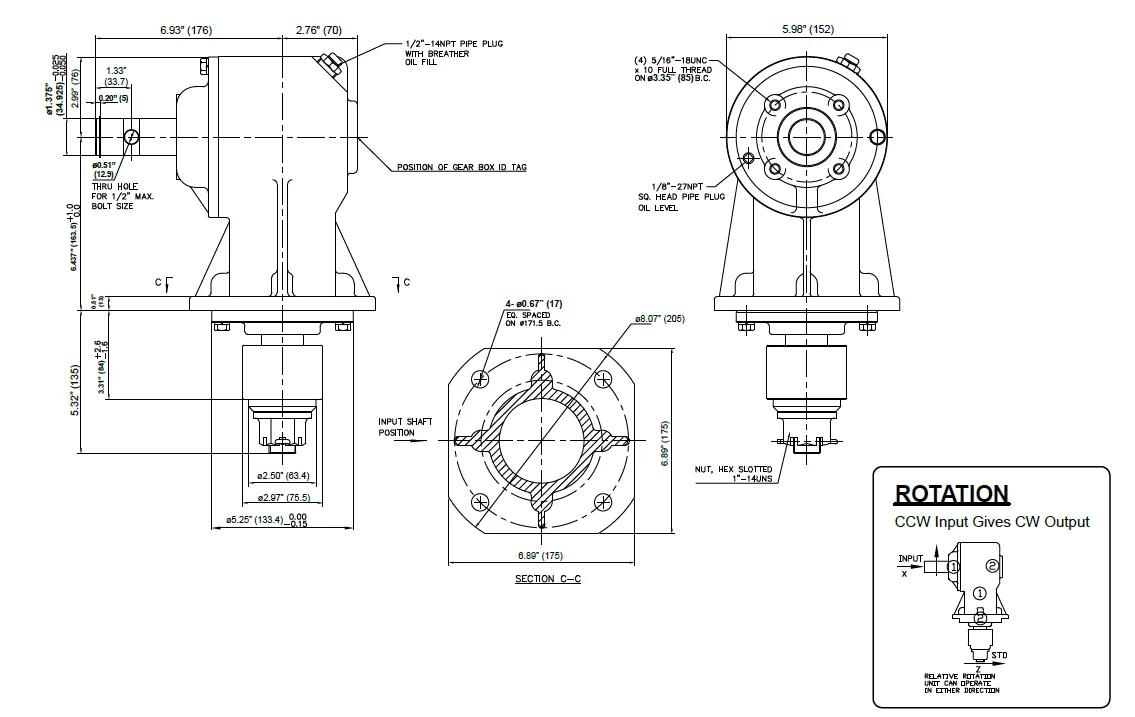

RC51 Rotary Cutter Gearbox Specifications

| Model | EPT-RC51 Rotary Cutter Gearbox |

| Torque | 2,800 - 4,667 lb.-in. (316 - 527 Nm.) |

| Ratios | 1:1.47, 1:1.71, 1:1.93 |

| Gear Type | Bevel |

| Seal Type | Triple Lip Spring Loaded |

| Bearing Type | Tapered Roller, Deep Groove Ball |

| Oil Capacity | 27 oz. (0.80 L) |

| Weight | 56 lbs. (25.4 kg.) |

Extended Applications and Benefits

1. Agricultural Efficiency with RC51 Gearbox

The RC51 rotary cutter gearbox is a game-changer for farmers and landscapers in Argentina and beyond. Its compatibility with a range of rotary cutters makes it perfect for agricultural gearbox applications such as pasture maintenance, crop residue management, and land clearing. The gearbox’s ability to handle torque up to 4,667 lb.-in. ensures it can power through dense vegetation with ease. For example, in a typical scenario, a farmer using a tractor-mounted rotary cutter can rely on the RC51 to maintain large fields, reducing downtime and repair costs.

| Application | Benefit |

|---|---|

| Pasture Maintenance | Fast clearing of weeds and brush |

| Crop Residue Management | Efficient cutting for soil preparation |

| Land Clearing | Handles thick vegetation with high torque |

2. Industrial Durability and Material Versatility

Beyond agriculture, the RC51 shines in industrial rotary cutter applications. Its construction from high-quality materials like cast iron, paired with advanced heat treatment processes (carbonitriding, carburization, and vacuum quenching), ensures it withstands harsh environments. Whether you’re clearing roadside vegetation or maintaining industrial lots, this gearbox offers longevity and cost-efficiency—delivering up to 50% cost savings compared to original products. Its versatility extends to various mounting ratios (1:1.47, 1:1.71, 1:1.93), making it adaptable to diverse machinery setups.

About Tebsa - Your Trusted Gearbox Manufacturer

Tebsa, based in Argentina, has been a professional experienced manufacturer since 1997, specializing in transmission components like the RC51 Rotary Cutter Gearbox. With a commitment to 100% quality guarantee, we offer a wide range of products including Gearboxes, Gears & Racks, Sprockets, Chains, Pulleys, Shaft Collars, Drive Shafts, Couplings, and Hydraulic Cylinders. Our talented engineering team provides feedback within 24 hours, ensuring smooth cooperation. Certified under ISO9001-2015, we leverage competitive strategic marketing to deliver high-performance solutions at 50% lower costs than competitors. From fast prototyping to mass production, Tebsa is your reliable partner for all transmission needs.

Frequently Asked Questions (FAQs)

- 1. What is the RC51 Rotary Cutter Gearbox used for?

- It’s designed for heavy-duty rotary cutters to clear vegetation like brush, weeds, and thick grass in agricultural and industrial settings.

- 2. How durable is the RC51 gearbox?

- Made with cast iron housing, heavy-duty gears, and triple lip seals, it’s built for long-lasting performance under high torque conditions.

- 3. Can the RC51 gearbox be installed on any rotary cutter?

- Yes, it features a simple bolt-on connection compatible with most rotary cutters, including replacements for Omni Gearbox RC-51.

- 4. What maintenance does the RC51 require?

- It’s easy to disassemble for cleaning and lubrication, with a 27 oz. oil capacity ensuring smooth operation.

- 5. Why choose Tebsa for agricultural gearboxes?

- Tebsa offers over 25 years of expertise, ISO-certified quality, and cost-effective solutions with rapid engineering support.

About us

We guarantee top-quality products at the best prices in China! Special orders are welcome, and if you’re interested in any of our products, feel free to reach out for more detailed information. We ensure our products are safe, high-quality, and reasonably priced. Please contact us as soon as possible if you’d like to learn more. We’re eager to cooperate with you!

A large portion of our products is exported to Europe and the Americas, with both standard and custom options available. We can manufacture according to your drawings or samples, using standard materials or as per your specific requirements. Choosing us means choosing reliability.

Materials Available

1. Stainless Steel: SS201, SS303, SS304, SS316, SS416, SS420

2. Steel:C45(K1045), C46(K1046),C20

3. Brass:C36000 ( C26800), C37700 ( HPb59), C38500( HPb58), C27200(CuZn37), C28000(CuZn40)

4. Bronze: C51000, C52100, C54400, etc

5. Iron: 1213, 12L14,1215

6. Aluminum: Al6061, Al6063

7.OEM according to your request

Surface Treatment

Annealing, natural canonization, heat treatment, polishing, nickel plating, chrome plating, zinc plating,yellow passivization, gold passivization, satin, Black surface painted etc.

Processing Method

CNC machining, punch,turning, milling, drilling, grinding, broaching, welding and assembly

QC & Certificate

Technicians self-check in production,final-check before package by professional Quality inspector

ISO9001:2008 , ISO14001:2001,ISO/TS 16949:2009

Package & Lead Time

Size: Drawings

Wooden Case/Container and pallet, or as per customized specifications.

15-25days samples. 30-45days offcial order

Port: Shanghai/Ningbo port

Industries We Service