Agricultural Lawn Mower Gearbox EP-RC31-193 EP-RC31-147

The RC-31 rotary cutter gearbox from TEBSA, Argentina’s trusted manufacturer since 1997, is engineered for demanding agricultural and landscaping tasks. Designed to replace the Omni Gear RC-31 series, models EP-RC31-193 and EP-RC31-147 deliver reliable power for rotary mowers, lawn maintenance, pasture management, and field clearing across Argentina’s diverse terrains, from the Pampas plains to Córdoba’s rolling fields. With a 100% quality guarantee and a 50% cost advantage over original brands, TEBSA ensures top performance at a practical price.

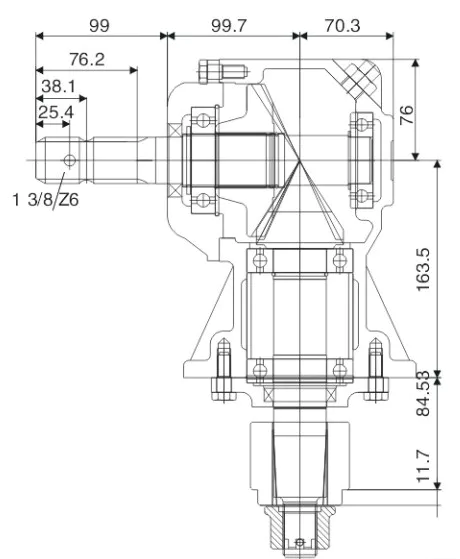

This gearbox features a right-angle design with horizontal input and vertical downward output, using bevel gears for smooth power transfer. Large deep groove ball bearings support the output shaft, handling heavy loads with ease. It comes with four 5/16"-18 tapped holes on a 4-1/8" diameter bolt circle for secure mounting. Shipped without oil, users must add lubricant before operation, following TEBSA’s manual for optimal results. Whether you’re cutting soybean rows or maintaining rural properties in Buenos Aires, the RC-31 is built to last.

Technical Specifications of RC-31 Rotary Cutter Gearbox

| ITEM | EP-RC31-193 | EP-RC31-147 |

| Ratio | 1:1.93 | 1:1.47 |

| Teeth | 15/29 | 15/22 |

| Module | 4.0 | 5.08 |

| Power(HP) | 30 | 40 |

| Rated Input | 540rpm | 540rpm |

| Input/Output Description | 1-3/8 Z6 Cone base aequilate spline shaft | |

| Weight(N.W) | 24.5KG | 24.5KG |

Detailed Features and Design

The RC-31 rotary cutter gearbox is a workhorse for farmers and landscapers needing precision and power. Its key features include:

- Rotation Flexibility: Counterclockwise (CCW) input delivers clockwise (CW) output, ideal for standard rotary mowers.

- Gear Ratio Options: The EP-RC31-193 offers a 1:1.93 ratio, while the EP-RC31-147 provides a 1:1.47 ratio, suiting different cutting speeds.

- Input/Output RPM: Accepts 540 or 1000 RPM input, producing 788 to 1460 RPM output for efficient blade performance.

- Power Capacity: Handles 35-83 HP, with a maximum torque of 4083-9683 in.lbs., perfect for medium to heavy-duty tasks.

- Shaft Design: Input shaft is 1-3/8" diameter with a 6-tooth spline and 5/16" pinhole; output shaft is 2" diameter with 15 tapered spline teeth and a threaded end, measuring 4-5/8" long.

- Blade Hub: 3.94" diameter hub steps down to 2.5" and tapers to 2.175", ensuring secure blade attachment.

- Mounting: Four holes on an 8" diameter bolt circle, with a 5-5/8" pilot for stable installation.

- Compact Size: Measures 12-3/8" x 9-3/4" x 9-3/4", weighing 89 lbs. (shipping weight).

Crafted with alloy steel and processed through advanced techniques like carburization and grinding, the RC-31 withstands the wear and tear of Argentina’s demanding fields. Its bevel gear system ensures smooth operation, while the cone base spline shaft enhances power transfer efficiency. Whether you’re mowing wheat fields in Santa Fe or clearing brush in Mendoza, this gearbox delivers consistent results.

Applications and Benefits in Argentine Agriculture

The RC-31 rotary cutter gearbox shines in a range of agricultural and landscaping applications across Argentina. Its primary uses include:

- Pasture Management: Keeps grazing lands in top shape for cattle ranchers in the Pampas, cutting tough grasses with ease.

- Crop Residue Clearing: Chops soybean and corn stubble post-harvest, preparing fields for the next planting season in regions like Córdoba.

- Lawn and Park Maintenance: Powers mowers for clean, professional cuts in Buenos Aires’ urban green spaces or rural estates.

- Roadside Clearing: Tackles overgrown vegetation along highways or farm paths, ensuring safe access.

The benefits of choosing TEBSA’s RC-31 are clear:

| Benefit | Description |

| Durability | Alloy steel gears and cast iron housing resist Argentina’s harsh sun, dust, and rain. |

| Efficiency | High-torque design maximizes blade speed, cutting work time on large fields. |

| Cost Savings | 50% cheaper than original brands, backed by TEBSA’s quality commitment. |

| Versatility | Two gear ratios fit various mowers, from small tractors to larger setups. |

| Easy Maintenance | Simple oil checks and part replacements, with TEBSA support in 24 hours. |

Farmers in Argentina trust the RC-31 for its ability to handle tough jobs without breaking the bank. Its design supports quick setups and reliable performance, whether you’re maintaining a vineyard in Mendoza or clearing land in Rosario. The gearbox’s robust bearings reduce wear, ensuring long-term use even in dusty, high-vibration environments.

Installation and Maintenance Tips

To get the most out of your RC-31 rotary cutter gearbox, proper setup and care are key. Here’s how to keep it running smoothly:

- Add Oil Before Use: The gearbox ships dry, so fill it with high-quality gear oil as per TEBSA’s manual to protect internal components.

- Check Alignment: Ensure the gearbox mounts flush with your mower to avoid strain on the shaft or bearings.

- Inspect Regularly: Look for oil leaks, gear wear, or loose bolts, especially after heavy use in Argentina’s dry or muddy fields.

- Lubricate Properly: Use TEBSA-recommended lubricants to maintain smooth gear movement and prevent overheating.

- Monitor Performance: Watch for unusual noises or vibrations, and contact our team in Buenos Aires for fast support if needed.

For detailed specs, consider the following comparison of the two models:

| Feature | EP-RC31-193 | EP-RC31-147 |

| Ideal Use | Light to medium mowing (pastures, lawns) | Heavier tasks (crop residue, brush) |

| Power Handling | Up to 30 HP | Up to 40 HP |

| Gear Module | 4.0 for smoother low-speed cuts | 5.08 for faster, heavier cuts |

By following these steps, you’ll extend the gearbox’s life and keep your equipment cutting cleanly, whether you’re working small plots or sprawling estancias.

About TEBSA and Our Agricultural Solutions

Since 1997, TEBSA has been Argentina’s go-to source for agricultural gearboxes, built with precision and backed by a 100% quality guarantee. Based in Argentina, we combine global expertise with local know-how, serving farmers from Salta to Patagonia. Our 50% cost advantage and 24-hour response team make us a reliable partner for your machinery needs. Certified to ISO9001-2015, we use advanced processes like forging, heat treatment, and precision grinding to deliver products that stand up to tough conditions.

Beyond the RC-31 rotary cutter gearbox, TEBSA offers a wide range of agricultural solutions:

- Fertilizer Spreader Gearboxes: For precise nutrient distribution in soybean and wheat fields.

- Post Hole Digger Gearboxes: Built for quick, deep digging in Argentina’s varied soils.

- Rotary Tiller Gearboxes: Perfect for preparing seedbeds in Córdoba or Santa Fe.

- Flail Mower Gearboxes: Ideal for heavy-duty clearing of brush or crop residue.

- PTO Shafts: Durable links between tractors and implements for seamless power transfer.

Looking to buy a rotary cutter gearbox in Argentina? TEBSA’s RC-31 models, like the EP-RC31-193 and EP-RC31-147, offer unmatched value and performance. Contact us today to learn more about our full lineup or get a quote tailored to your farm’s needs.

About us

We guarantee top-quality products at the best prices in China! Special orders are welcome, and if you’re interested in any of our products, feel free to reach out for more detailed information. We ensure our products are safe, high-quality, and reasonably priced. Please contact us as soon as possible if you’d like to learn more. We’re eager to cooperate with you!

A large portion of our products is exported to Europe and the Americas, with both standard and custom options available. We can manufacture according to your drawings or samples, using standard materials or as per your specific requirements. Choosing us means choosing reliability.

Materials Available

1. Stainless Steel: SS201, SS303, SS304, SS316, SS416, SS420

2. Steel:C45(K1045), C46(K1046),C20

3. Brass:C36000 ( C26800), C37700 ( HPb59), C38500( HPb58), C27200(CuZn37), C28000(CuZn40)

4. Bronze: C51000, C52100, C54400, etc

5. Iron: 1213, 12L14,1215

6. Aluminum: Al6061, Al6063

7.OEM according to your request

Surface Treatment

Annealing, natural canonization, heat treatment, polishing, nickel plating, chrome plating, zinc plating,yellow passivization, gold passivization, satin, Black surface painted etc.

Processing Method

CNC machining, punch,turning, milling, drilling, grinding, broaching, welding and assembly

QC & Certificate

Technicians self-check in production,final-check before package by professional Quality inspector

ISO9001:2008 , ISO14001:2001,ISO/TS 16949:2009

Package & Lead Time

Size: Drawings

Wooden Case/Container and pallet, or as per customized specifications.

15-25days samples. 30-45days offcial order

Port: Shanghai/Ningbo port

Industries We Service