Agricultural Lawn Mower Gearbox EP-RC61

When you’re working long hours in Argentina’s fields—whether it’s soybean harvests in the Pampas or pasture upkeep in Córdoba—you need gear that doesn’t quit. The EP-RC61 rotary cutter gearbox from TEBSA delivers the muscle and reliability to keep your rotary cutter humming. Built to handle tough jobs like crop residue management, lawn maintenance, or construction site clearing, this gearbox is your go-to for smooth operation and top-notch performance. Since 1997, TEBSA has stood by a 100% quality guarantee, offering equipment that’s both durable and budget-friendly with a 50% cost advantage over original brands.

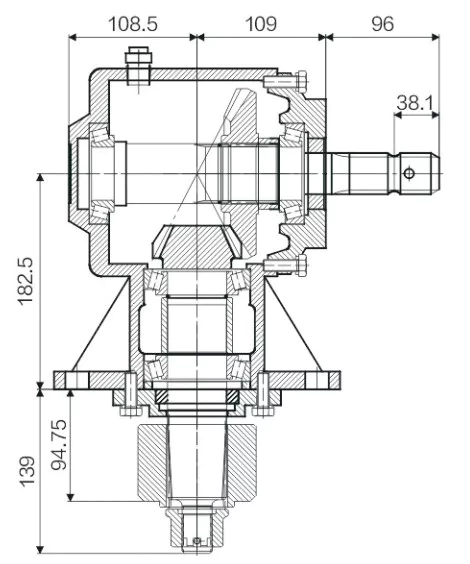

Key Specifications of the EP-RC61 Rotary Cutter Gearbox

| ITEM | EP-RC61 |

| Ratio | 1:1.46/1:1.93 |

| Teeth | 19/13 27/14 |

| Module | 7.0 / 5.5 |

| Power(HP) | 60 |

| Rated Input | 540rpm |

| Input/Output Description | 1-3/8 Z6 Taper spline |

| Weight(N.W) | 36.5KG |

Why the EP-RC61 Stands Out for Tough Jobs

The EP-RC61 isn’t just another gearbox—it’s a workhorse designed for the real-world demands of farming and industrial tasks. Whether you’re mowing thick pasture grass or clearing overgrown lots, this gearbox keeps your rotary cutter running strong. Its 60 HP power rating and 540 RPM input make it a perfect match for mid-sized tractors commonly used in Argentina’s agricultural heartlands. The dual gear ratios (1:1.46 and 1:1.93) let you tweak performance for different jobs, from light mowing to heavy chopping.

What sets it apart is the build. TEBSA crafts each unit with high-speed ball bearings and heat-treated alloy steel gears and shafts, ensuring they hold up under strain. The 1-3/8 Z6 taper spline input/output fits standard PTO setups, so you’re not stuck hunting for odd parts. Weighing 36.5 kg, it’s sturdy without bogging down your equipment. Plus, it comes with a blade carrier mounting nut for quick setup. Shipped dry, it needs lubricating oil meeting industry specs—simple to source and easy to maintain.

This gearbox matches industry standards, so it’s a reliable replacement for brands like Omni, fitting seamlessly into your existing rotary cutter. For Argentine farmers dealing with crops like wheat, corn, or soybeans, the EP-RC61 handles the residue and rough terrain with ease. Its compact design cuts down on vibration, meaning less wear on your machine and more hours in the field.

Applications and Benefits Tailored for Argentina

The EP-RC61 rotary cutter gearbox shines in a range of scenarios, making it a favorite for farmers, landscapers, and contractors across Argentina. Here’s where it excels:

Crop Management: Tackle post-harvest residue in soybean or corn fields, common in Buenos Aires province, to prep land for the next planting.

Pasture Maintenance: Keep grazing lands in top shape for Argentina’s cattle industry, especially in the Pampas where grass grows thick.

Lawn and Lot Care: Clear overgrown areas for rural properties or urban projects, from Mendoza vineyards to Rosario estates.

Construction Support: Level brush and debris on job sites, a must for infrastructure growth in Argentina’s expanding regions.

The benefits go beyond versatility. First, it’s efficient—high-speed bearings and precision gears mean power flows smoothly, saving fuel and time. Second, it’s tough. TEBSA’s forging and carburization processes, honed since 1997, make the EP-RC61 resistant to the dust, heat, and jolts of fieldwork. Third, it’s safe. A solid gearbox reduces the risk of sudden failures, keeping operators secure during long days. Fourth, it’s low-maintenance—check the oil, grease the splines, and you’re set for seasons of use.

For Argentine buyers, the 50% cost savings compared to original brands is a game-changer. You get the same performance without draining your budget, whether you’re a small farmer in Santa Fe or a contractor in Salta. And with TEBSA’s engineering team responding within 24 hours, support is always close by.

To give you a clearer picture, here’s how the EP-RC61 fits into common setups:

| Application | Equipment Type | Key Feature | Argentine Use Case |

|---|---|---|---|

| Crop Residue Cutting | Rotary Mower | High Torque (up to 60 HP) | Soybean fields in Buenos Aires |

| Pasture Mowing | Flail Mower | Dual Gear Ratios | Cattle ranches in the Pampas |

| Land Clearing | Brush Cutter | Durable Alloy Steel | Construction sites in Córdoba |

Technical Edge and Maintenance Tips

The EP-RC61’s technical design is where TEBSA’s expertise shines. The bevel gears, with teeth counts of 19/13 and 27/14, deliver precise power transfer, while the 7.0/5.5 module ensures a balance of strength and smoothness. Heat-treated alloy steel, often finished with blackening or powder coating, resists corrosion—a big plus in Argentina’s humid climates. The tapered roller seals keep dirt out, protecting the internals during dusty harvests.

Maintenance is straightforward, which matters when you’re racing against planting schedules. Fill it with high-quality gear oil (32 oz capacity) before use, and check levels every season. Grease the taper spline regularly to avoid wear on the PTO connection. A quick visual scan for leaks or cracks keeps small issues from turning big. TEBSA’s ISO9001-2015 certification backs every unit, so you know it’s built to last.

For buyers searching online, terms like “buy rotary cutter gearbox in Argentina” or “reliable 60 HP gearbox for farming” lead straight to the EP-RC61. Its specs match what farmers need—540 RPM input, 60 HP capacity, and a weight that won’t overload your tractor. Whether you’re upgrading a worn-out unit or outfitting a new mower, this gearbox delivers without fuss.

About TEBSA and Our Range of Agricultural Gearboxes

TEBSA, based in Argentina since 1997, is your trusted partner for agricultural machinery components. We started with a mission to deliver reliable, cost-effective solutions, and today, we’re proud to offer a 100% quality guarantee on every product. Our 50% cost advantage comes from smart manufacturing—forging, casting, and precision machining in materials like alloy steel, stainless steel, and aluminum. With a talented engineering team ready to answer your questions within 24 hours, we’re here to keep your operation moving.

Beyond the EP-RC61, TEBSA supplies a full lineup of agricultural gearboxes to suit Argentina’s diverse needs:

Fertilizer Spreader Gearboxes: For even nutrient distribution in corn and wheat fields.

Lawn Mower Gearboxes: For clean cuts on rural estates or urban parks.

Post Hole Digger Gearboxes: For fencing projects across the Pampas.

Rotary Tiller Gearboxes: For soil prep in Mendoza’s vineyards.

Flail Mower Gearboxes: For heavy-duty clearing in rugged terrain.

We also offer PTO shafts, sprockets, chains, pulleys, and hydraulic cylinders, all built to the same high standards. Whether you’re in Buenos Aires, Rosario, or Salta, TEBSA’s gear gets the job done. Ready to upgrade your equipment? Contact us today to explore our range or get a quote.

About us

We guarantee top-quality products at the best prices in China! Special orders are welcome, and if you’re interested in any of our products, feel free to reach out for more detailed information. We ensure our products are safe, high-quality, and reasonably priced. Please contact us as soon as possible if you’d like to learn more. We’re eager to cooperate with you!

A large portion of our products is exported to Europe and the Americas, with both standard and custom options available. We can manufacture according to your drawings or samples, using standard materials or as per your specific requirements. Choosing us means choosing reliability.

Materials Available

1. Stainless Steel: SS201, SS303, SS304, SS316, SS416, SS420

2. Steel:C45(K1045), C46(K1046),C20

3. Brass:C36000 ( C26800), C37700 ( HPb59), C38500( HPb58), C27200(CuZn37), C28000(CuZn40)

4. Bronze: C51000, C52100, C54400, etc

5. Iron: 1213, 12L14,1215

6. Aluminum: Al6061, Al6063

7.OEM according to your request

Surface Treatment

Annealing, natural canonization, heat treatment, polishing, nickel plating, chrome plating, zinc plating,yellow passivization, gold passivization, satin, Black surface painted etc.

Processing Method

CNC machining, punch,turning, milling, drilling, grinding, broaching, welding and assembly

QC & Certificate

Technicians self-check in production,final-check before package by professional Quality inspector

ISO9001:2008 , ISO14001:2001,ISO/TS 16949:2009

Package & Lead Time

Size: Drawings

Wooden Case/Container and pallet, or as per customized specifications.

15-25days samples. 30-45days offcial order

Port: Shanghai/Ningbo port

Industries We Service