Fertilizer Mixer Gearboxes – Replacement of Comer Code MR-90 1:1

The MR-90 fertilizer mixer gearbox, crafted by TEBSA in Argentina, is a rugged mechanical component built for agricultural tasks like blending and mixing fertilizers. Since 1997, TEBSA has delivered reliable solutions with a 100% quality guarantee, and this gearbox is no exception. It transforms the rotational power from a tractor’s PTO (Power Take-Off) shaft into the linear motion needed to drive the mixing blades of fertilizer mixers, ensuring smooth and efficient operation across Argentina’s farmlands.

Constructed from heavy-duty cast iron GG25, the MR-90 withstands the intense torque and forces generated during fertilizer mixing. It offers a 1:1 gear ratio, with customizable options to suit various fertilizer types, from granular to liquid blends. This adaptability makes it a go-to choice for farmers in regions like Buenos Aires or the Pampas, where crops like soybean and corn thrive. Sealed bearings protect internal gears from dust and debris, cutting down on maintenance and extending service life. The result is a gearbox that runs quietly and reliably, even in tough conditions.

The MR-90’s input shaft connects seamlessly to the tractor’s PTO, while the output shaft drives the mixer’s blades with precision. This setup ensures efficient power transfer, critical for consistent fertilizer blending. With TEBSA’s 50% cost advantage over original brands, the MR-90 delivers top performance at a budget-friendly price, backed by a skilled engineering team ready to respond within 24 hours.

Choosing the right MR-90 model means matching it to your mixer’s horsepower (up to 62.6 kW) and torque (1071 Nm) needs. This ensures peak efficiency and durability, whether you’re mixing fertilizers for small plots or large-scale operations in Argentina’s agricultural heartlands.

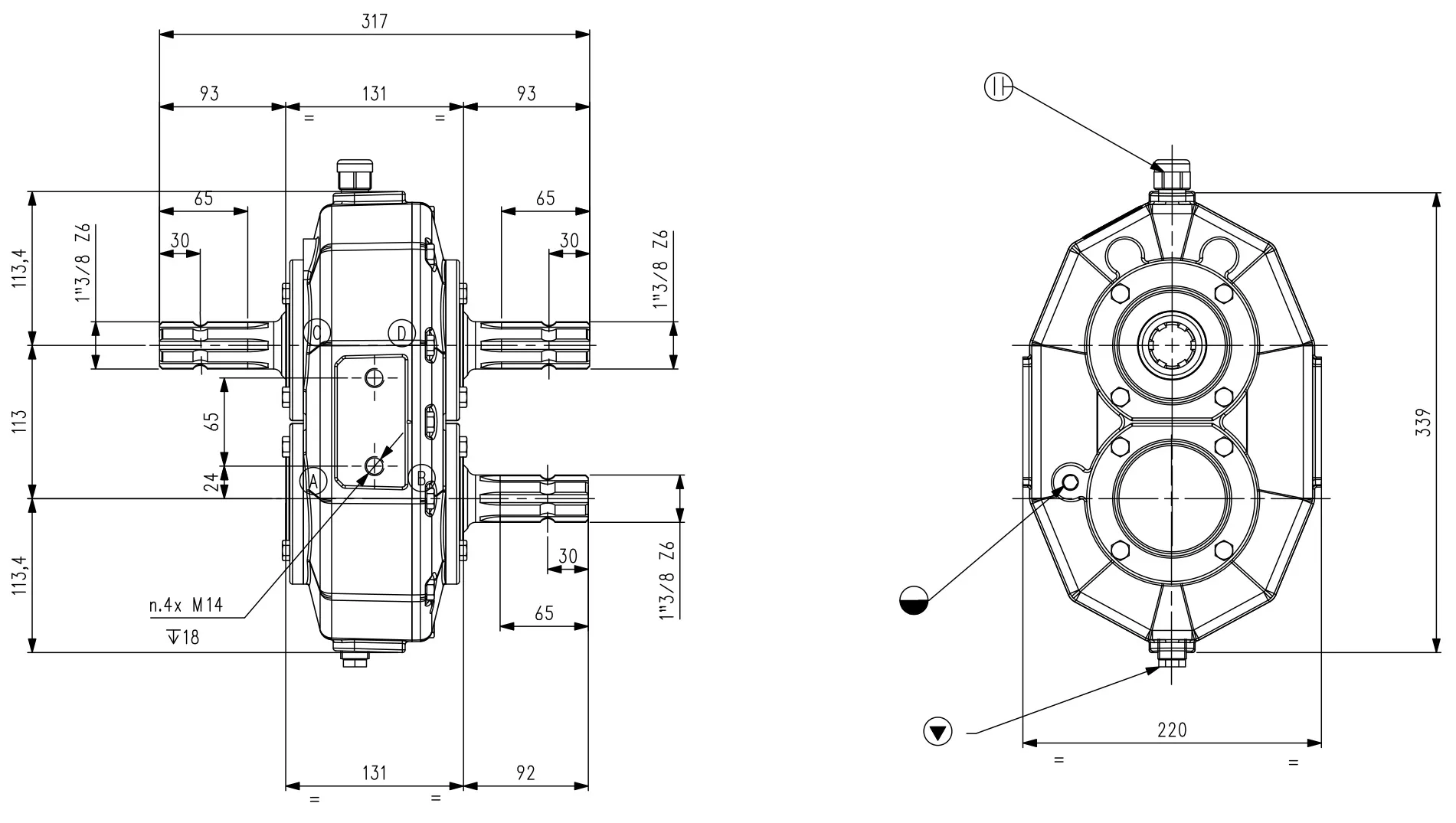

Specifications of Fertilizer Mixer Gearbox MR-90 (1:1)

| Product Description | Fertilizer Mixer Gearboxes - Replacement of Comer Gearbox MR-90 1:1 |

|---|---|

| Product details |

|

| Application range |

|

| Consists of |

|

| Max. input power | 62.6 kW |

| Max. output torque | 1071 nm |

| Max. output torque | 107.1 daNm |

| Contains oil | No |

| Max. oil capacity | 0.8 l |

| Max. oil change interval | 500 h |

| Oil SAE viscosity grade | 80W-90 |

| Housing material | Cast iron GG25 |

| Weight | 27.5 kg |

| Gear arrangement | 43 - 44 |

| Ratio | 1:1 |

| Input section | Y |

| Input shaft | Y |

| Shaft X | 1 3/8" (6) (C) |

| Shaft Y | 1 3/8" (6) (A) |

| Shaft Z | 1 3/8" (6) (A) |

Applications of the MR-90 Fertilizer Mixer Gearbox in Argentine Agriculture

The MR-90 fertilizer mixer gearbox is a cornerstone for farmers across Argentina, from the fertile Pampas to the fields of Córdoba and Santa Fe. It powers fertilizer mixers that blend granular, liquid, or compound fertilizers, ensuring even distribution for crops like soybean, corn, and wheat—key to Argentina’s agricultural output. Its robust cast iron GG25 housing and sealed bearings make it ideal for dusty, high-torque environments, where debris from fertilizer materials could otherwise wear down equipment.

This gearbox shines in both small-scale farms and large agribusinesses. For example, a farmer in Buenos Aires might use it to mix nitrogen-rich fertilizers for soybean planting, while a cooperative in Rosario could rely on it for bulk blending of phosphate-based mixes. The 1:1 gear ratio delivers consistent power, but TEBSA offers custom ratios for specialized needs, such as mixing denser organic fertilizers. Its compatibility with standard 1 3/8" PTO shafts ensures it fits most tractors used in Argentina, from compact models to heavy-duty ones.

The MR-90 also supports precision agriculture, a growing trend in Argentina. By ensuring uniform fertilizer blends, it helps farmers apply nutrients accurately, boosting crop yields while minimizing waste. Whether you’re preparing fields for planting or maintaining pastures, this gearbox delivers the reliability needed to keep operations running smoothly.

Key Benefits of the MR-90 Fertilizer Mixer Gearbox

The MR-90 from TEBSA offers a range of advantages tailored to Argentina’s farming needs:

Top-Notch Durability: Built with cast iron GG25 and treated with advanced processes like carburization, it handles the high torque of fertilizer mixing without breaking a sweat. It’s designed to last through years of tough use in Argentina’s varied climates.

Smooth Power Transfer: The splined input and output shafts ensure efficient energy flow from the tractor’s PTO to the mixer blades, reducing wear and boosting mixing performance.

Low Maintenance: Sealed bearings keep out dust and fertilizer particles, cutting down on upkeep. A simple oil change schedule—first at 50-70 hours, then every 500-700 hours—keeps it running like new.

Cost Savings: TEBSA’s 50% cost advantage over original brands makes the MR-90 a smart investment for farmers looking to maximize value without sacrificing quality.

Versatile Performance: The 1:1 gear ratio suits most fertilizer types, but customizable options let you tweak it for specific blends, from lightweight granules to heavy compounds.

Quiet Operation: Sealed bearings and precision engineering mean less noise, creating a better work environment for operators in Argentina’s fields.

Local Support: TEBSA’s engineering team, based in Argentina since 1997, responds within 24 hours to any questions or customization needs.

These benefits make the MR-90 a trusted choice for farmers and agribusinesses seeking efficiency, durability, and affordability.

Maintenance Tips for the MR-90 Fertilizer Mixer Gearbox

To keep the MR-90 performing at its best, follow these maintenance steps:

Initial Setup: The gearbox ships without oil. Fill it with 0.8 liters of 80W-90 oil before use to ensure smooth operation.

Oil Changes: Replace the oil after the first 50-70 hours of use, then every 500-700 hours or annually. Check for contaminants to protect internal gears.

Regular Inspections: Look for leaks, cracks, or wear on the housing and shafts every few months, especially after heavy use in dusty conditions.

Bearing Care: The sealed bearings are low-maintenance, but ensure they remain free of debris buildup to maintain quiet performance.

Shaft Alignment: Confirm the input and output shafts are properly aligned with the tractor’s PTO and mixer blades to avoid strain or vibration.

Lubrication: Use only high-quality 80W-90 oil approved by TEBSA to maintain optimal viscosity and gear protection.

By sticking to these steps, you’ll extend the gearbox’s lifespan and avoid costly downtime. TEBSA’s team is always a call away for maintenance advice or replacement parts.

Why Choose TEBSA for Agricultural Gearboxes

Since 1997, TEBSA has been a trusted name in Argentina’s agricultural sector, delivering high-quality gearboxes with a 100% quality guarantee. Based in Argentina, we understand the unique needs of local farmers, from the Pampas to the northern provinces. Our ISO9001-2015 certification reflects our commitment to precision manufacturing, using advanced techniques like forging, carburization, and powder coating. With a 50% cost advantage over original brands and a responsive engineering team, we’re your reliable partner for agricultural solutions.

Beyond the MR-90 fertilizer mixer gearbox, TEBSA offers a wide range of products, including:

Rotary Cutter Gearboxes: Like the RC-61, perfect for mowing and clearing.

Fertilizer Spreader Gearboxes: For even nutrient distribution.

Lawn Mower Gearboxes: Built for precision cutting.

Post Hole Digger Gearboxes: Ideal for fencing and planting.

Rotary Tiller Gearboxes: For soil preparation.

PTO Shafts: Durable power transfer for various implements.

Whether you’re in Buenos Aires, Córdoba, or Mendoza, TEBSA’s products are designed to boost productivity and durability. Contact us today to explore our full range or request a quote for the MR-90 fertilizer mixer gearbox!

Frequently Asked Questions (FAQ)

| Question | Answer |

|---|---|

| What fertilizers can the MR-90 mix? | It handles granular, liquid, and compound fertilizers, with customizable gear ratios for specific blends. |

| Is the MR-90 compatible with my tractor? | It fits most tractors with a 1 3/8" PTO shaft. Contact TEBSA for compatibility details. |

| How often should I change the oil? | First change after 50-70 hours, then every 500-700 hours or yearly. |

| Can I use the MR-90 in dusty conditions? | Yes, its sealed bearings protect against dust and debris, common in Argentina’s fields. |

About us

We guarantee top-quality products at the best prices in China! Special orders are welcome, and if you’re interested in any of our products, feel free to reach out for more detailed information. We ensure our products are safe, high-quality, and reasonably priced. Please contact us as soon as possible if you’d like to learn more. We’re eager to cooperate with you!

A large portion of our products is exported to Europe and the Americas, with both standard and custom options available. We can manufacture according to your drawings or samples, using standard materials or as per your specific requirements. Choosing us means choosing reliability.

Materials Available

1. Stainless Steel: SS201, SS303, SS304, SS316, SS416, SS420

2. Steel:C45(K1045), C46(K1046),C20

3. Brass:C36000 ( C26800), C37700 ( HPb59), C38500( HPb58), C27200(CuZn37), C28000(CuZn40)

4. Bronze: C51000, C52100, C54400, etc

5. Iron: 1213, 12L14,1215

6. Aluminum: Al6061, Al6063

7.OEM according to your request

Surface Treatment

Annealing, natural canonization, heat treatment, polishing, nickel plating, chrome plating, zinc plating,yellow passivization, gold passivization, satin, Black surface painted etc.

Processing Method

CNC machining, punch,turning, milling, drilling, grinding, broaching, welding and assembly

QC & Certificate

Technicians self-check in production,final-check before package by professional Quality inspector

ISO9001:2008 , ISO14001:2001,ISO/TS 16949:2009

Package & Lead Time

Size: Drawings

Wooden Case/Container and pallet, or as per customized specifications.

15-25days samples. 30-45days offcial order

Port: Shanghai/Ningbo port

Industries We Service