Horizontal Feed Mixer Gearbox-Replacement of Comer D732A Gearbox 1:1/1.93:1

The Horizontal Feed Mixer Gearbox, designed as a direct replacement for the Comer D732A, is a vital component for agricultural feed mixing operations in Argentina. Engineered by TEBSA, a trusted manufacturer since 1997, this gearbox matches the original’s specifications for seamless compatibility and top-tier performance. Built to handle the demanding task of mixing feed for livestock, it ensures efficiency and reliability in tough farming environments like the Pampas plains. With a 100% quality guarantee and a 50% cost advantage over original brands, TEBSA delivers a durable, high-value solution.

Crafted from cast iron GG25, the gearbox resists wear and tear, standing up to continuous use in feed processing. Its precision-machined gears and bearings manage heavy loads, while the reinforced housing minimizes maintenance needs. Custom gear ratios (1:1 or 1.93:1) optimize mixing for specific tasks, boosting productivity for Argentine farmers handling soybean, corn, or cattle feed. This replacement gearbox keeps your operation running smoothly, cutting downtime and enhancing output.

Why Choose the TEBSA D732A Replacement Gearbox?

The TEBSA Horizontal Feed Mixer Gearbox stands out for its robust design and practical benefits, tailored to the needs of Argentina’s agricultural sector. Here’s why it’s a smart choice:

Seamless Compatibility: Engineered to replace the Comer D732A, it fits existing feed mixers perfectly, ensuring quick installation and no modifications. This makes it ideal for farmers in Buenos Aires or Córdoba looking to upgrade without hassle.

High Durability: Made from cast iron and featuring heat-treated gears (via carburization), it withstands the rigors of daily feed mixing, from small dairy farms to large cattle operations.

Optimized Performance: With gear ratios of 1:1 or 1.93:1, it delivers precise power transfer, improving mixing consistency for livestock feed, whether for poultry, swine, or cattle.

Low Maintenance: The reinforced housing and tapered roller seals reduce wear, while simple oil changes (every 500-700 hours) keep it running smoothly.

Cost Savings: TEBSA’s 50% cost advantage over original gearboxes means you get premium quality without breaking the bank, a key factor for Argentine agribusinesses.

Local Support: Our engineering team, based in Argentina, responds within 24 hours, offering expert guidance for installation, maintenance, or customization.

This gearbox is a reliable partner for feed mixer wagons, ensuring consistent performance in Argentina’s diverse farming landscape, from soybean fields to grazing pastures.

Technical Specifications and Features

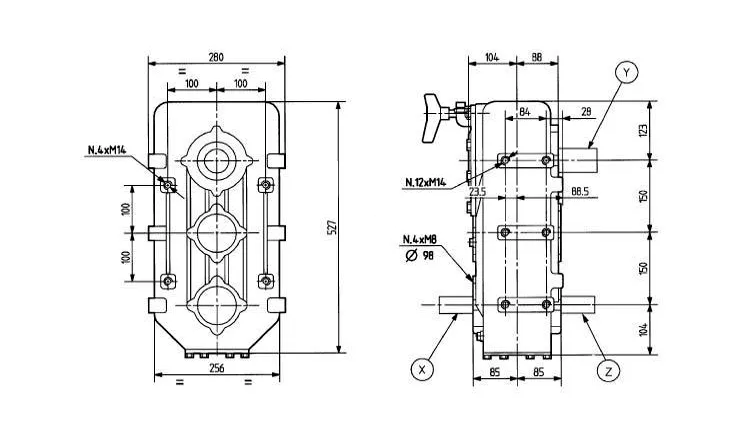

The TEBSA D732A replacement gearbox is built for precision and power, with specifications designed to meet the demands of horizontal feed mixers. Below are the key details:

| Product Description |

Horizontal Feed Mixer Gearbox-Replacement of Comer D732A Gearbox 1:1/1.93:1

|

|---|---|

| Product details |

|

| Application range |

Mixing wagon

|

| Ratio factor |

1:1.93

|

| Consists of |

|

| Max. input power |

59 kW

|

| Max. output power |

80 HP

|

| Connection 1 outside diameter |

1-3/8 Inch

|

| Connection 1 number of splines |

6

|

| Connection 2 outside diameter |

60 mm

|

| Contains oil |

No

|

| Max. oil capacity |

5.6 l

|

| Max. oil change interval |

500 h

|

| Oil SAE viscosity grade |

80W-90

|

| Housing material |

Cast iron GG25

|

| Weight |

63 kg

|

Additional Technical Features

- Precision Machining: Gears are hobbed and ground for smooth power transfer, reducing noise and wear.

- Heat Treatment: Carburized gears enhance hardness, ideal for Argentina’s high-intensity feed mixing tasks.

- Sealing System: Tapered roller seals prevent leaks, protecting internal components from dust and moisture in humid regions like Entre Ríos.

Applications and Maintenance for Argentine Farms

The TEBSA D732A replacement gearbox is designed for horizontal feed mixer wagons, a staple in Argentina’s livestock industry. Whether you’re blending feed for cattle in Santa Fe or poultry in Mendoza, this gearbox ensures uniform mixing, critical for animal health and farm efficiency. Its 80 HP output and 59 kW input power suit medium to large-scale operations, while the 1:1.93 gear ratio optimizes torque for thick feed blends.

Key Applications

| Application | Description | Relevant Keywords |

|---|---|---|

| Cattle Feed Mixing | Blends corn, soybean, and silage for dairy and beef cattle in the Pampas. | Feed mixer gearbox for cattle, agricultural gearbox Argentina |

| Poultry Feed Processing | Handles fine grains for poultry farms in Buenos Aires. | Poultry feed mixer gearbox, cast iron gearbox for feed |

| Swine Feed Production | Mixes high-protein feeds for pig farms in Córdoba. | Swine feed gearbox, durable feed mixer gearbox |

Maintenance Tips

To keep the gearbox in top shape:

Initial Setup: Fill with 5.6 liters of 80W-90 oil before use, as it ships without oil.

Oil Changes: Replace oil after 50-70 hours, then every 500-700 hours or annually.

Inspections: Check for leaks or wear monthly, especially in dusty regions like La Pampa.

Alignment: Ensure the gearbox and mixer are aligned to avoid strain on the 1-3/8-inch, 6-spline connection.

Lubrication: Use only manufacturer-approved 80W-90 oil to maintain gear integrity.

Regular care prevents downtime, ensuring your feed mixer stays productive during Argentina’s busy harvest seasons. TEBSA’s team is available 24/7 to answer questions or provide spare parts, keeping your operation on track.

About TEBSA and Our Agricultural Solutions

Since 1997, TEBSA has been a leading manufacturer of agricultural gearboxes in Argentina, delivering reliable, cost-effective solutions to farmers and industrial operators. Based in Argentina, we pride ourselves on a 100% quality guarantee, a 50% cost advantage over original brands, and a skilled engineering team that responds within 24 hours. Certified under ISO9001-2015, we use advanced processes like forging, carburization, and precision grinding to produce durable products tailored to Argentina’s farming needs.

In addition to the Horizontal Feed Mixer Gearbox, TEBSA offers a wide range of agricultural gearboxes, including:

Rotary Cutter Gearboxes: For mowing and crop residue management.

Fertilizer Spreader Gearboxes: For precise nutrient distribution.

Rotary Tiller Gearboxes: For soil preparation in soybean and wheat fields.

Flail Mower Gearboxes: For heavy-duty vegetation control.

PTO Shafts: For efficient power transfer in farm machinery.

Whether you’re in Buenos Aires, Mendoza, or Santa Fe, TEBSA is your trusted partner for agricultural gearboxes. Contact us today to learn more about the D732A replacement gearbox or explore our full product lineup.

About us

We guarantee top-quality products at the best prices in China! Special orders are welcome, and if you’re interested in any of our products, feel free to reach out for more detailed information. We ensure our products are safe, high-quality, and reasonably priced. Please contact us as soon as possible if you’d like to learn more. We’re eager to cooperate with you!

A large portion of our products is exported to Europe and the Americas, with both standard and custom options available. We can manufacture according to your drawings or samples, using standard materials or as per your specific requirements. Choosing us means choosing reliability.

Materials Available

1. Stainless Steel: SS201, SS303, SS304, SS316, SS416, SS420

2. Steel:C45(K1045), C46(K1046),C20

3. Brass:C36000 ( C26800), C37700 ( HPb59), C38500( HPb58), C27200(CuZn37), C28000(CuZn40)

4. Bronze: C51000, C52100, C54400, etc

5. Iron: 1213, 12L14,1215

6. Aluminum: Al6061, Al6063

7.OEM according to your request

Surface Treatment

Annealing, natural canonization, heat treatment, polishing, nickel plating, chrome plating, zinc plating,yellow passivization, gold passivization, satin, Black surface painted etc.

Processing Method

CNC machining, punch,turning, milling, drilling, grinding, broaching, welding and assembly

QC & Certificate

Technicians self-check in production,final-check before package by professional Quality inspector

ISO9001:2008 , ISO14001:2001,ISO/TS 16949:2009

Package & Lead Time

Size: Drawings

Wooden Case/Container and pallet, or as per customized specifications.

15-25days samples. 30-45days offcial order

Port: Shanghai/Ningbo port

Industries We Service