Bevel Gear

Miter Gears

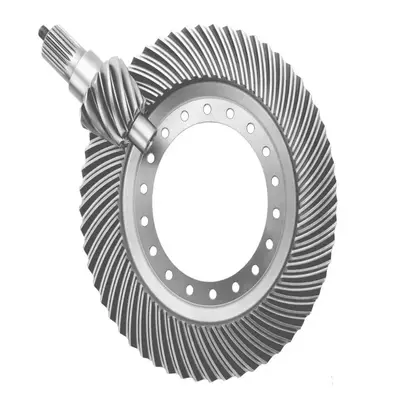

Spiral Bevel Gears

90-degree Bevel Gears

Hypoid Gears

Plastic Bevel Gears

Our Bevel Gear Types for Agricultural Machinery

| Gear Type | Material | Applications | Key Feature | Torque Range |

|---|---|---|---|---|

| 90 Degree Bevel Gears | Alloy Steel | Rotary Cutters, Harvesters | High Strength | 50–500 Nm |

| Spiral Bevel Gears | Stainless Steel | Tractors, Combines | Low Vibration | 100–800 Nm |

| Miter Gears | Cast Iron/Alloy Steel | Irrigation Pumps, Mowers | 1:1 Ratio | 20–200 Nm |

| Helical Bevel Gears | Alloy Steel | Tillers, Balers | High Torque | 200–1000 Nm |

| Zero-degree Spiral Bevel Gears | Stainless Steel | Seeders, Sprayers | High Precision | 50–300 Nm |

| Plastic Bevel Gears | POM/Nylon | Greenhouses, Conveyors | Corrosion-Resistant | 5–50 Nm |

Applications of Bevel Gears in Argentine Agriculture

Bevel gears from TEBSA are the backbone of Argentina’s farm machinery, redirecting power at precise 90-degree angles to keep equipment like tractors, mowers, and harvesters running smoothly. Since 1997, we’ve tailored our gears to meet the demands of Argentina’s diverse agricultural landscape, from the fertile Pampas plains to the vineyards of Mendoza. Whether you’re plowing fields in Buenos Aires or harvesting crops in Santa Fe, our bevel gears—built with alloy steel and advanced forging—deliver reliability at half the cost of original brands. Backed by a 100% quality guarantee and 24-hour support, they’re designed to boost productivity in the following key applications:

Tractor Transmission Systems

Bevel gears are critical for transferring power from the tractor’s PTO (power take-off) to attachments like plows or seeders. In Córdoba, where soybean farming dominates, our spiral bevel gears ensure smooth torque delivery, letting farmers till vast fields efficiently. Their carburized surfaces resist wear, even during long hours of heavy plowing in the humid Pampas summers.

Rotary Mowers and Cutters

For pasture maintenance in regions like La Pampa, bevel gears drive the blades of rotary mowers, chopping grass or crop residue with precision. Our straight bevel gears fit smaller mowers for grazing fields, while spiral gears handle heavy-duty cutters clearing wheat stubble. This versatility keeps ranches productive, and our 50% cost edge makes upgrades affordable.

Grain Harvesters

In Santa Fe’s corn and wheat belts, bevel gears power the complex internals of combine harvesters, ensuring headers and threshers work in sync. Our hypoid bevel gears, designed for offset shafts, excel in modern harvesters, cutting downtime during peak seasons. Farmers trust TEBSA’s gears to handle the dusty, high-load conditions of Argentina’s harvest months.

Get Your Bevel Gears Today

Ready to keep your farm equipment running smoothly? TEBSA’s bevel gears, crafted with alloy steel since 1997, power tractors and mowers across Argentina’s Pampas. With a 100% quality guarantee and 50% cost savings, we make upgrading easy. Fill out the form below, and our team will get back to you within 24 hours with solutions for your soybean or wheat harvests.

Why Choose us?

When you pick TEBSA’s bevel gears for your farm equipment, you’re getting more than just a component—you’re investing in performance that lasts. Since 1997, we’ve fine-tuned our gears to meet the needs of Argentina’s farmers, from Córdoba’s soybean fields to Mendoza’s orchards. Here’s why our bevel gears stand out:

Top Efficiency

Our bevel gears transfer power at 90 degrees with minimal loss, driving tractors and mowers smoothly. They save fuel and cut faster, whether you’re mowing pasture in Santa Fe or plowing in Buenos Aires. Built to fit standard PTO shafts, they’re ready to roll without hassle.

Built to Last

Made from alloy steel and forged for toughness, our gears handle Pampas dust and humid summers. Carburized for extra strength, they resist wear and tear, keeping your machinery running season after season. With our 100% quality guarantee, you’re covered.

Big Cost Savings

Get premium bevel gears at 50% less than big brands. Our efficient manufacturing keeps prices low without skimping on quality. Fewer replacements and easy upkeep mean more money stays in your pocket for farms in Rosario or beyond.

Works Everywhere