Adjustable Pulleys

Adjustable Pulleys: A Versatile Solution for Infrequent Speed Changes

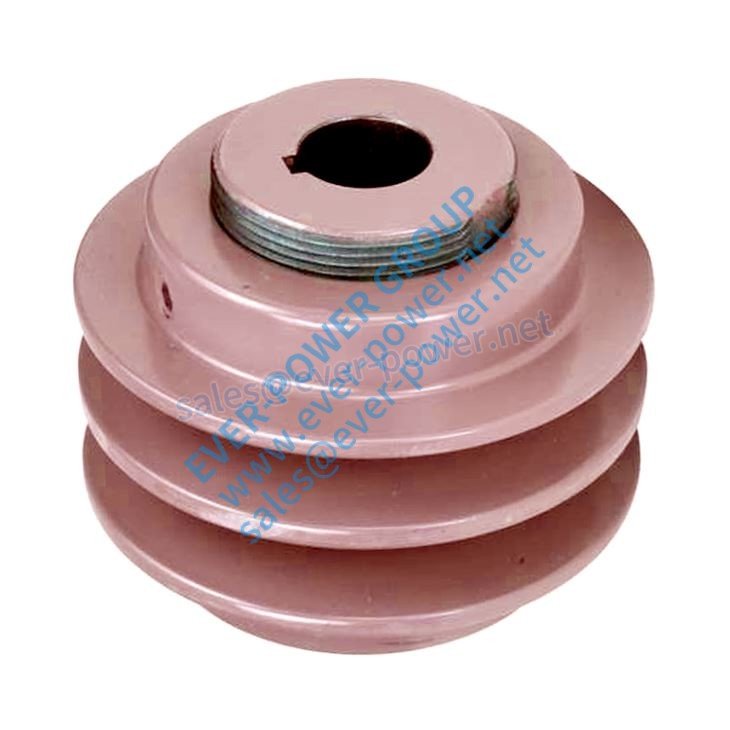

Adjustable pulleys, also known as "variable speed pulleys," are a type of pulley system capable of wide speed variation. They are a versatile solution for applications where the speed change is infrequent and where variable speed is required. These pulleys are fitted with Taper-bushing for ease of installation and dismantling.

Uni-Drive UD Pulleys: A Unique Construction

Uni-Drive UD pulleys have a unique construction that sets them apart from other adjustable pulleys. As the pulley is adjusted in pitch diameter, the belt does not remain in line, creating a slight angle at which Uni-drive Vee-belts operate. Despite the non-linear belt position, this slight angle does not appreciably shorten the belt life or lower the efficiency of the drive. However, careful alignment is necessary, with the driving and driven shafts parallel. In the case of a single groove, a Uni-drive Vee-belt should run at right angles to the shafts with the Uni-Drive UD pulley set to give a mean belt position. A drive using two belts should be set so that the center-line of both the twin groove Uni-drive UD and the mating pulley are directly in line.

Advantages of Adjustable Pulleys

Adjustable pulleys have several advantages over fixed pulleys. They can be adjusted to accommodate changes in the speed of the driven pulley, without requiring the belt to be replaced. This makes them a cost-effective solution for applications where variable speed is required. They are also easy to install and dismantle, thanks to the Taper-bushing. Plus, the slight angle at which Uni-drive Vee-belts operate does not appreciably shorten the belt life or lower the efficiency of the drive.

Installation, Maintenance, and Repair

To ensure optimal performance, adjustable pulleys must be carefully aligned, with the driving and driven shafts parallel. In the case of a single groove, a Uni-drive Vee-belt should run at right angles to the shafts with the Uni-Drive UD pulley set to give a mean belt position. A drive using two belts should be set so that the center-line of both the twin groove Uni-drive UD and the mating pulley are directly in line. Regular maintenance is essential to ensure the longevity and proper function of the pulleys. This includes regular cleaning, lubrication, and inspection of the pulley system. If repairs are needed, it is important to use genuine spare parts to maintain the quality and performance of the pulleys.

Material and Classification

Adjustable pulleys can be made from a variety of materials, including steel, aluminum, and plastic. They can be classified according to the type of pulley, such as fixed pulleys, movable pulleys, and compound pulleys. Adjustable pulleys fall under the category of variable speed pulleys, which allow for changes in the speed of the driven pulley.

Other Products from Our Company

In addition to adjustable pulleys, our company supplies various plastic gear used in industry, such as agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, detachable chains, pulleys and pulleys, planetary gearboxes, timing pulleys, bushings, and more. We take pride in providing high-quality products at favorable prices, along with considerate service. We welcome customers to come to us for drawing or sample customization to meet their specific needs.

Q&A:

Q: What are adjustable pulleys?

A: Adjustable pulleys, also known as "variable speed pulleys," are a type of pulley system capable of wide speed variation. They are a versatile solution for applications where the speed change is infrequent and where variable speed is required.

Q: How do I install adjustable pulleys?

A: To ensure optimal performance, adjustable pulleys must be carefully aligned, with the driving and driven shafts parallel. In the case of a single groove, a Uni-drive Vee-belt should run at right angles to the shafts with the Uni-Drive UD pulley set to give a mean belt position. A drive using two belts should be set so that the center-line of both the twin groove Uni-drive UD and the mating pulley are directly in line.

Q: What materials can adjustable pulleys be made from?

A: Adjustable pulleys can be made from a variety of materials, including steel, aluminum, and plastic.

Q: What are the advantages of adjustable pulleys?

A: Adjustable pulleys have several advantages over fixed pulleys. They can be adjusted to accommodate changes in the speed of the driven pulley, without requiring the belt to be replaced. This makes them a cost-effective solution for applications where variable speed is required. They are also easy to install and dismantle, thanks to the Taper-bushing.

Q: How do I maintain adjustable pulleys?

A: Regular maintenance is essential to ensure the longevity and proper function of the pulleys. This includes regular cleaning, lubrication, and inspection of the pulley system.

Q: What other products does your company supply?

A: In addition to adjustable pulleys, our company supplies various plastic gear used in industry, such as agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, detachable chains, pulleys and pulleys, planetary gearboxes, timing pulleys, bushings, and more.

About us

We guarantee top-quality products at the best prices in China! Special orders are welcome, and if you’re interested in any of our products, feel free to reach out for more detailed information. We ensure our products are safe, high-quality, and reasonably priced. Please contact us as soon as possible if you’d like to learn more. We’re eager to cooperate with you!

A large portion of our products is exported to Europe and the Americas, with both standard and custom options available. We can manufacture according to your drawings or samples, using standard materials or as per your specific requirements. Choosing us means choosing reliability.

Materials Available

1. Stainless Steel: SS201, SS303, SS304, SS316, SS416, SS420

2. Steel:C45(K1045), C46(K1046),C20

3. Brass:C36000 ( C26800), C37700 ( HPb59), C38500( HPb58), C27200(CuZn37), C28000(CuZn40)

4. Bronze: C51000, C52100, C54400, etc

5. Iron: 1213, 12L14,1215

6. Aluminum: Al6061, Al6063

7.OEM according to your request

Surface Treatment

Annealing, natural canonization, heat treatment, polishing, nickel plating, chrome plating, zinc plating,yellow passivization, gold passivization, satin, Black surface painted etc.

Processing Method

CNC machining, punch,turning, milling, drilling, grinding, broaching, welding and assembly

QC & Certificate

Technicians self-check in production,final-check before package by professional Quality inspector

ISO9001:2008 , ISO14001:2001,ISO/TS 16949:2009

Package & Lead Time

Size: Drawings

Wooden Case/Container and pallet, or as per customized specifications.

15-25days samples. 30-45days offcial order

Port: Shanghai/Ningbo port

Industries We Service