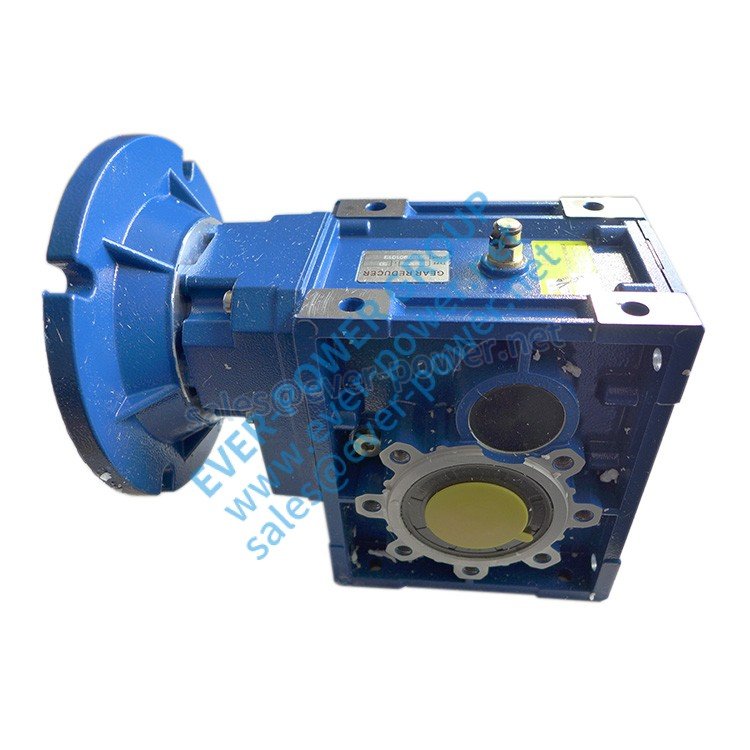

BKM series high efficiency hypoid gear box

BKM Series High Efficiency Hypoid Gear Box

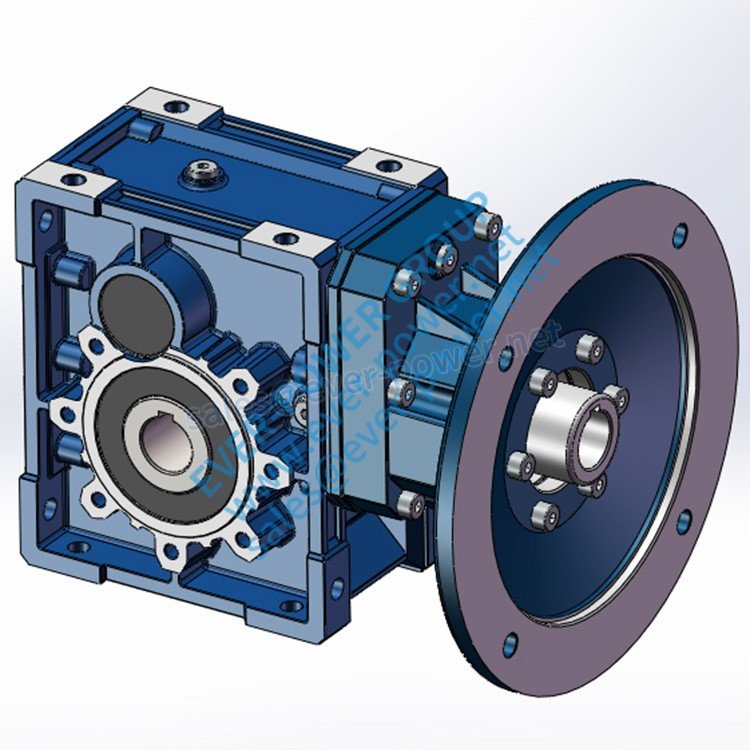

BKM series high efficiency hypoid gearbox is a new generation product developed by our company, which fuses advanced technology from both home and abroad. It is designed to solve the low transmission efficiency, short service life, and other related problems associated with EP-NMRV worm gearbox. The mounting dimension of BKM is the same as the EP-NMRV series worm gearbox and adopts gear transmission used for reference SEW helical gearbox structure to improve transmission efficiency. BKM is widely used in industrial development to save energy, reduce consumption, and promote green environmental protection.

Advantages of BKM Series High Efficiency Hypoid Gear Box

- Driven by hypoid gear, BKM has big ratios, making it suitable for various industrial applications.

- BKM provides high efficiency, energy saving, and environmental protection, making it a popular choice in the market.

- Made of high-quality aluminum alloy, BKM is light in weight and non-rusting, ensuring longevity of the product.

- BKM runs smoothly and quietly, even in dreadful conditions, making it ideal for long-term use.

- BKM has a durable service life, small in volume, and is good-looking in appearance.

- BKM is modular and multi-structure, meeting various conditions and demands.

- The mounting dimension of BKM series is compatible with the EP-NMRV series worm gear unit. (A part of EP-NMRV050 dimensions are different from BKM050)

Common Use Scenarios of BKM Series High Efficiency Hypoid Gear Box

BKM is widely used in various industrial applications, such as packaging machinery, printing machinery, textile machinery, food machinery, metallurgical machinery, and environmental protection machinery. It is also suitable for lifting equipment, transportation machinery, construction machinery, and other industrial fields that require high transmission efficiency and stability.

Installation, Maintenance, and Repair of BKM Series High Efficiency Hypoid Gear Box

When installing BKM, ensure that the gearbox is fixed properly and the output shaft is concentric with the input shaft. Regular maintenance is important, and the gearbox should be checked for any abnormal noise, oil leakage, or overheating. To repair BKM, the gearbox cover should be removed, and the internal gear should be checked for any deformation or damage.

Materials of BKM Series High Efficiency Hypoid Gear Box

BKM is made of high-quality aluminum alloy, which is light in weight and non-rusting. This ensures longevity and durability of the product. The gear is treated with high-frequency heat treatment technology to improve the hardness and wear resistance of the product, ensuring a long service life.

Other Products from Our Company

Our company mainly supplies various plastic gear used in industry, such as agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, detachable chains, pulleys and pulleys, planetary gearboxes, timing pulleys, bushings, and more. Our products are of high quality, favorable price, and considerate service. We welcome customers to come to the drawing or sample customization.

Q&A

Q1: What is BKM series high efficiency hypoid gearbox?

A1: BKM series high efficiency hypoid gearbox is a new generation product developed by our company, which fuses advanced technology from both home and abroad. It is designed to solve the low transmission efficiency, short service life, and other related problems associated with EP-NMRV worm gearbox.

Q2: What are the advantages of BKM series high efficiency hypoid gearbox?

A2: BKM provides high efficiency, energy saving, and environmental protection, making it a popular choice in the market. It runs smoothly and quietly, even in dreadful conditions, making it ideal for long-term use. BKM is modular and multi-structure, meeting various conditions and demands.

Q3: What are the common use scenarios of BKM series high efficiency hypoid gearbox?

A3: BKM is widely used in various industrial applications, such as packaging machinery, printing machinery, textile machinery, food machinery, metallurgical machinery, and environmental protection machinery. It is also suitable for lifting equipment, transportation machinery, construction machinery, and other industrial fields that require high transmission efficiency and stability.

Q4: What materials is BKM series high efficiency hypoid gearbox made of?

A4: BKM is made of high-quality aluminum alloy, which is light in weight and non-rusting. The gear is treated with high-frequency heat treatment technology to improve the hardness and wear resistance of the product, ensuring a long service life.

Q5: How to install, maintain, and repair BKM series high efficiency hypoid gearbox?

A5: When installing BKM, ensure that the gearbox is fixed properly and the output shaft is concentric with the input shaft. Regular maintenance is important, and the gearbox should be checked for any abnormal noise, oil leakage, or overheating. To repair BKM, the gearbox cover should be removed, and the internal gear should be checked for any deformation or damage.

About us

We guarantee top-quality products at the best prices in China! Special orders are welcome, and if you’re interested in any of our products, feel free to reach out for more detailed information. We ensure our products are safe, high-quality, and reasonably priced. Please contact us as soon as possible if you’d like to learn more. We’re eager to cooperate with you!

A large portion of our products is exported to Europe and the Americas, with both standard and custom options available. We can manufacture according to your drawings or samples, using standard materials or as per your specific requirements. Choosing us means choosing reliability.

Materials Available

1. Stainless Steel: SS201, SS303, SS304, SS316, SS416, SS420

2. Steel:C45(K1045), C46(K1046),C20

3. Brass:C36000 ( C26800), C37700 ( HPb59), C38500( HPb58), C27200(CuZn37), C28000(CuZn40)

4. Bronze: C51000, C52100, C54400, etc

5. Iron: 1213, 12L14,1215

6. Aluminum: Al6061, Al6063

7.OEM according to your request

Surface Treatment

Annealing, natural canonization, heat treatment, polishing, nickel plating, chrome plating, zinc plating,yellow passivization, gold passivization, satin, Black surface painted etc.

Processing Method

CNC machining, punch,turning, milling, drilling, grinding, broaching, welding and assembly

QC & Certificate

Technicians self-check in production,final-check before package by professional Quality inspector

ISO9001:2008 , ISO14001:2001,ISO/TS 16949:2009

Package & Lead Time

Size: Drawings

Wooden Case/Container and pallet, or as per customized specifications.

15-25days samples. 30-45days offcial order

Port: Shanghai/Ningbo port

Industries We Service