diy worm gear

DIY Worm Gear: An Essential Component for Mechanical Systems

Worm gears play a crucial role in transmitting motion and power between two perpendicular shafts. With their unique design and functionality, they find extensive application in various industries. In this article, we will explore the world of DIY worm gears, their history, classification, advantages, materials, installation, maintenance, repair, and replacement techniques.

A Brief History of Worm Gears

The concept of worm gears dates back thousands of years, with early examples found in ancient civilizations such as Egypt and Greece. However, it wasn't until the 19th century that worm gears gained recognition for their mechanical advantages and became widely used in industrial applications.

Classification of Worm Gears

- Single-Thread Worm Gears

- Double-Thread Worm Gears

- Multiple-Thread Worm Gears

- Non-Throated Worm Gears

Advantages of DIY Worm Gears

- High gear reduction ratio

- Compact size

- Self-locking capabilities

- Smooth and quiet operation

Materials for DIY Worm Gears

When it comes to DIY worm gears, various materials can be utilized based on the specific requirements of the application:

- Steel: Known for its strength and durability, steel worm gears are ideal for heavy-duty applications.

- Brass: Provides excellent wear resistance and is commonly used in low-speed applications.

- Bronze: Offers superior corrosion resistance and is suitable for marine and outdoor environments.

- Plastic: Lightweight and cost-effective, plastic worm gears are often used in less demanding applications.

Installation, Maintenance, and Repair

Proper installation, maintenance, and occasional repair are essential to ensure the longevity and optimal performance of DIY worm gears. Here are some key considerations:

- Installation: Align the worm gear and the worm wheel precisely, ensuring proper lubrication for smooth operation.

- Maintenance: Regularly inspect for signs of wear, debris, or inadequate lubrication. Clean and lubricate as necessary.

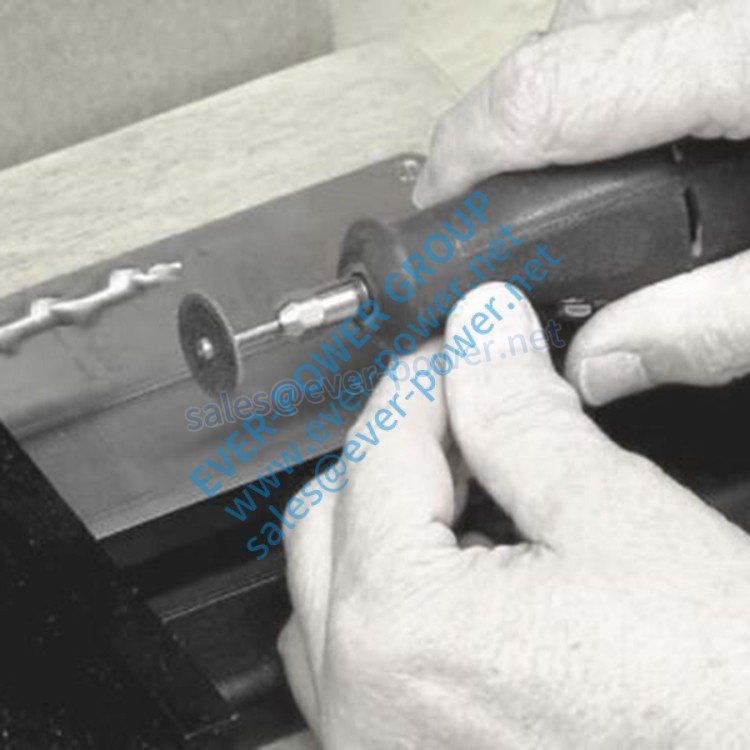

- Repair: In case of damage or wear, replace worn components and ensure proper alignment during reassembly.

Replacing a DIY Worm Gear

If the existing worm gear requires replacement, follow these steps:

- Remove the old worm gear by disassembling the mechanical system.

- Select a suitable replacement worm gear based on size, material, and tooth profile.

- Reassemble the mechanical system, ensuring proper alignment and lubrication.

Discover Our Wide Range of Industrial Plastic Gears

At our company, we are dedicated to supplying high-quality plastic gears for various industrial applications. Our extensive product range includes:

- Agricultural gearboxes

- Power output shafts

- Sprockets

- Fluid couplings

- Worm gear reducers

- Gears and racks

- Detachable chains

- Pulleys and pulleys

- Planetary gearboxes

- Timing pulleys

- Bushings

We take pride in offering products of exceptional quality, competitive prices, and providing excellent customer service. Whether you require standard solutions or customizations based on your drawings or samples, we are here to meet your specific needs. Join our growing list of satisfied customers and experience the difference firsthand!

Q&A

1. What are the main applications of DIY worm gears?

DIY worm gears are commonly used in various mechanical systems, including machinery, automotive, robotics, and industrial equipment.

2. Can plastic worm gears be used in high-speed applications?

Plastic worm gears are generally not recommended for high-speed applications due to their lower heat resistance and potential for wear.

3. How often should DIY worm gears be lubricated?

Regular lubrication is crucial for smooth operation. DIY worm gears should be lubricated as per the manufacturer's recommendations.

4. What factors should be considered when selecting a replacement worm gear?

When selecting a replacement worm gear, key factors to consider include size compatibility, tooth profile, material, and load-bearing capacity.

5. Can I rely on the company's custom gear manufacturing services?

Absolutely! Our company excels in providing custom gear manufacturing services. We welcome your drawing or sample customization requests and guarantee exceptional results.

About us

We guarantee top-quality products at the best prices in China! Special orders are welcome, and if you’re interested in any of our products, feel free to reach out for more detailed information. We ensure our products are safe, high-quality, and reasonably priced. Please contact us as soon as possible if you’d like to learn more. We’re eager to cooperate with you!

A large portion of our products is exported to Europe and the Americas, with both standard and custom options available. We can manufacture according to your drawings or samples, using standard materials or as per your specific requirements. Choosing us means choosing reliability.

Materials Available

1. Stainless Steel: SS201, SS303, SS304, SS316, SS416, SS420

2. Steel:C45(K1045), C46(K1046),C20

3. Brass:C36000 ( C26800), C37700 ( HPb59), C38500( HPb58), C27200(CuZn37), C28000(CuZn40)

4. Bronze: C51000, C52100, C54400, etc

5. Iron: 1213, 12L14,1215

6. Aluminum: Al6061, Al6063

7.OEM according to your request

Surface Treatment

Annealing, natural canonization, heat treatment, polishing, nickel plating, chrome plating, zinc plating,yellow passivization, gold passivization, satin, Black surface painted etc.

Processing Method

CNC machining, punch,turning, milling, drilling, grinding, broaching, welding and assembly

QC & Certificate

Technicians self-check in production,final-check before package by professional Quality inspector

ISO9001:2008 , ISO14001:2001,ISO/TS 16949:2009

Package & Lead Time

Size: Drawings

Wooden Case/Container and pallet, or as per customized specifications.

15-25days samples. 30-45days offcial order

Port: Shanghai/Ningbo port

Industries We Service