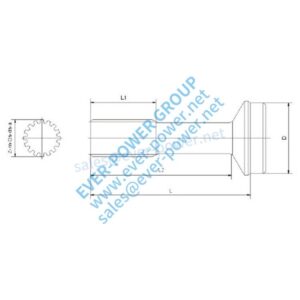

Driveshaft Yoke

Driveshaft Yoke: The Backbone of Your Vehicle's Power Transmission System

Driveshaft yoke, a crucial part of the power transmission system in vehicles, is responsible for transmitting torque from the transmission to the differential. It consists of a slip yoke and a universal joint that allows the driveshaft to flex and rotate while transmitting power from the engine to the wheels. The slip yoke assembly, located on the end of the driveshaft, allows the driveshaft to "slip" or flex with the movement of the suspension, preventing damage to the driveshaft or other components in the powertrain.

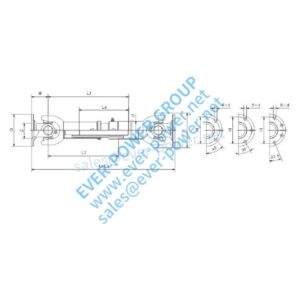

Types of Driveshaft Yokes

Driveshaft yokes come in various types, including the standard yoke, bolt-on yoke, weld yoke, and flange yoke. The choice of the yoke type depends on the specific application and the type of vehicle. For instance, heavy-duty trucks commonly use the weld yoke type, while passenger cars typically use the bolt-on or flange yoke.

Benefits of Using Driveshaft Yokes

Driveshaft yokes offer several advantages, such as:

- Increased durability and strength

- Improved power transfer efficiency

- Reduced vibration and noise

- Lower maintenance costs

- Easy installation and repair

How to Install and Maintain Driveshaft Yokes

Installing and maintaining driveshaft yokes requires some technical knowledge and expertise. Here are some tips:

Installation:

- Ensure all parts are clean and free of debris and contaminants

- Align the yoke with the transmission output shaft and the differential input shaft

- Install the U-joint into the yoke and secure with snap rings or retaining clips

- Align the U-joint with the driveshaft and install it into the yoke

- Secure the driveshaft with bolts and torque to the recommended specs

Maintenance:

- Inspect the yoke for cracks, wear, or damage regularly

- Grease the U-joints and yoke regularly to prevent wear and damage

- Replace the U-joints and yoke if they show signs of wear or damage

- Check the bolts and fasteners for tightness regularly

Replacing Driveshaft Yokes

If the driveshaft yoke is damaged or worn beyond repair, it must be replaced with a new one. Replacing a driveshaft yoke involves removing the driveshaft from the vehicle, removing the old yoke, and installing the new one. It is recommended to have a professional mechanic or technician perform this task to ensure proper installation and alignment.

Other Products We Offer

In addition to driveshaft yokes, we offer a wide range of industrial plastic gears, such as agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, detachable chains, pulleys and pulleys, planetary gearboxes, timing pulleys, bushings, and more. Our products are of the highest quality, competitively priced, and backed by excellent customer service. We welcome custom orders based on drawings or samples, and we strive to meet your unique needs with our expertise in the field. Contact us today for more information!

Q&A

1. What is a driveshaft yoke?

A driveshaft yoke is a component of the power transmission system in vehicles that is responsible for transmitting torque from the transmission to the differential. It consists of a slip yoke and a universal joint that allows the driveshaft to flex and rotate while transmitting power from the engine to the wheels.

2. What are the types of driveshaft yokes?

Driveshaft yokes come in various types, including the standard yoke, bolt-on yoke, weld yoke, and flange yoke. The choice of yoke type depends on the specific application and the type of vehicle.

3. What are the benefits of using driveshaft yokes?

Driveshaft yokes offer several advantages, such as increased durability and strength, improved power transfer efficiency, reduced vibration and noise, lower maintenance costs, and easy installation and repair.

4. How do you install and maintain driveshaft yokes?

Installing and maintaining driveshaft yokes requires technical knowledge and expertise. It involves cleaning and inspecting the parts regularly, aligning the yoke with the transmission output shaft and the differential input shaft, installing the U-joint into the yoke, aligning the U-joint with the driveshaft, securing the driveshaft with bolts, and torquing to the recommended specs.

5. How do you replace a driveshaft yoke?

If the driveshaft yoke is damaged or worn beyond repair, it must be replaced with a new one. Replacing a driveshaft yoke involves removing the driveshaft from the vehicle, removing the old yoke, and installing the new one. It is recommended to have a professional mechanic or technician perform this task to ensure proper installation and alignment.

About us

We guarantee top-quality products at the best prices in China! Special orders are welcome, and if you’re interested in any of our products, feel free to reach out for more detailed information. We ensure our products are safe, high-quality, and reasonably priced. Please contact us as soon as possible if you’d like to learn more. We’re eager to cooperate with you!

A large portion of our products is exported to Europe and the Americas, with both standard and custom options available. We can manufacture according to your drawings or samples, using standard materials or as per your specific requirements. Choosing us means choosing reliability.

Materials Available

1. Stainless Steel: SS201, SS303, SS304, SS316, SS416, SS420

2. Steel:C45(K1045), C46(K1046),C20

3. Brass:C36000 ( C26800), C37700 ( HPb59), C38500( HPb58), C27200(CuZn37), C28000(CuZn40)

4. Bronze: C51000, C52100, C54400, etc

5. Iron: 1213, 12L14,1215

6. Aluminum: Al6061, Al6063

7.OEM according to your request

Surface Treatment

Annealing, natural canonization, heat treatment, polishing, nickel plating, chrome plating, zinc plating,yellow passivization, gold passivization, satin, Black surface painted etc.

Processing Method

CNC machining, punch,turning, milling, drilling, grinding, broaching, welding and assembly

QC & Certificate

Technicians self-check in production,final-check before package by professional Quality inspector

ISO9001:2008 , ISO14001:2001,ISO/TS 16949:2009

Package & Lead Time

Size: Drawings

Wooden Case/Container and pallet, or as per customized specifications.

15-25days samples. 30-45days offcial order

Port: Shanghai/Ningbo port

Industries We Service