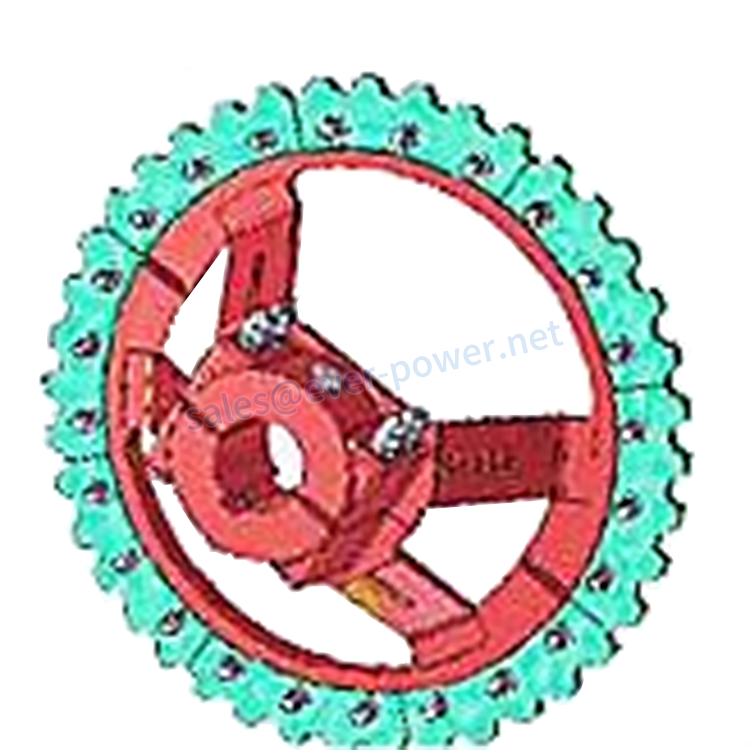

Environmental Chain Sprockets

Environmental Chain Sprockets

The environmental chain sprockets are a crucial component in various industrial applications. These sprockets are designed to provide efficient power transmission and smooth operation in environmentally sensitive conditions. They are available in different configurations to suit specific requirements.

Product History and Classification

The history of chain sprockets dates back to the early industrial revolution when they were used in machinery to transmit motion and power. Over the years, they have evolved to meet the demands of modern industries. Environmental chain sprockets can be categorized into different types based on their construction and materials:

- Non-metallic - Made from nylon materials or UHMW-PE with stainless steel hardware

- Combination - Features a cast iron body with UHMW segmented teeth

- Split sprockets

- Shear pin assemblies

- Dished (offset) sprockets

- Sprockets and traction wheels for traveling water screens (bodies and replacement teeth)

Advantages of Environmental Chain Sprockets

Environmental chain sprockets offer several advantages in industrial applications:

- Highly durable and resistant to wear

- Excellent chemical resistance

- Low friction and noise levels

- Corrosion-resistant

- Can operate efficiently in harsh environments

Product Materials

These sprockets are manufactured using high-quality materials to ensure their reliability and longevity. Some common materials used include:

- Nylon

- UHMW-PE (Ultra-High Molecular Weight Polyethylene)

- Cast iron

- Stainless steel

Usage Scenarios and Installation

Environmental chain sprockets find applications in various industries, including wastewater treatment, mining, food processing, and more. They are commonly used in:

- Conveyor systems

- Mechanical power transmission systems

- Water treatment plants

- Industrial machinery

Installing these sprockets requires careful consideration of alignment and proper tensioning. It is crucial to follow the manufacturer's guidelines for installation to ensure optimal performance.

Maintenance and Repair

To maintain the functionality and extend the lifespan of environmental chain sprockets, regular maintenance is essential. Some recommended maintenance practices include:

- Regular lubrication

- Inspection for wear and damage

- Tension adjustment

- Replacing worn-out or damaged components

When repairs are needed, it is recommended to consult a professional or contact the original supplier for guidance.

Product Replacement

Over time, environmental chain sprockets may require replacement due to wear or changes in operational requirements. When replacing the sprockets, it is crucial to consider the specifications and compatibility with the existing system. Consulting the original supplier for guidance is recommended to ensure the proper selection and installation of replacement sprockets.

Company's Other Product Businesses

Aside from environmental chain sprockets, our company specializes in providing a wide range of industrial plastic gears and related accessories. Our product offerings include:

- Agricultural gearboxes

- Power output shafts

- Hydraulic couplings

- Worm gear reducers

- Gear racks

- Removable chains

- Pulleys and pulleys

- Planetary gearboxes

- Timing pulleys

- Bushings

We take pride in offering high-quality products at competitive prices. Our dedicated team ensures outstanding customer service and welcomes customization requests based on specific needs. Feel free to contact us with any inquiries or requests.

FAQs

Q1: Can environmental chain sprockets be used in corrosive environments?

A1: Yes, environmental chain sprockets are designed to be corrosion-resistant and can operate efficiently in corrosive environments.

Q2: What is the recommended maintenance frequency for these sprockets?

A2: Regular maintenance, including lubrication and inspection, should be performed as per the manufacturer's recommendations. The frequency may vary depending on the operating conditions.

Q3: Are environmental chain sprockets compatible with different chain types?

A3: Yes, environmental chain sprockets are available in various tooth profiles and sizes to accommodate different chain types.

Q4: Can damaged sprocket teeth be repaired?

A4: In most cases, damaged sprocket teeth cannot be repaired. It is recommended to replace the entire sprocket or consult a professional for further evaluation.

Q5: Are these sprockets suitable for high-speed applications?

A5: Yes, environmental chain sprockets are designed to handle high-speed applications while maintaining optimal performance and reliability.

Author: lmc

Disclaimer: All the content on this page is sourced from the internet and is intended only as a reference for product selection. Our products are aftermarket accessories and not original spare parts. We do not hold the original trademark of the content. Our accessories perfectly fit the original spare parts. If you need to purchase original spare parts, please contact the original factory.

About us

We guarantee top-quality products at the best prices in China! Special orders are welcome, and if you’re interested in any of our products, feel free to reach out for more detailed information. We ensure our products are safe, high-quality, and reasonably priced. Please contact us as soon as possible if you’d like to learn more. We’re eager to cooperate with you!

A large portion of our products is exported to Europe and the Americas, with both standard and custom options available. We can manufacture according to your drawings or samples, using standard materials or as per your specific requirements. Choosing us means choosing reliability.

Materials Available

1. Stainless Steel: SS201, SS303, SS304, SS316, SS416, SS420

2. Steel:C45(K1045), C46(K1046),C20

3. Brass:C36000 ( C26800), C37700 ( HPb59), C38500( HPb58), C27200(CuZn37), C28000(CuZn40)

4. Bronze: C51000, C52100, C54400, etc

5. Iron: 1213, 12L14,1215

6. Aluminum: Al6061, Al6063

7.OEM according to your request

Surface Treatment

Annealing, natural canonization, heat treatment, polishing, nickel plating, chrome plating, zinc plating,yellow passivization, gold passivization, satin, Black surface painted etc.

Processing Method

CNC machining, punch,turning, milling, drilling, grinding, broaching, welding and assembly

QC & Certificate

Technicians self-check in production,final-check before package by professional Quality inspector

ISO9001:2008 , ISO14001:2001,ISO/TS 16949:2009

Package & Lead Time

Size: Drawings

Wooden Case/Container and pallet, or as per customized specifications.

15-25days samples. 30-45days offcial order

Port: Shanghai/Ningbo port

Industries We Service