EP-RC61T Rotary Cutter Gearbox for Rotary Cutter

Introduction of RC61T Rotary Cutter Gearbox

The RC61T rotary cutter gearbox from TEBSA, Argentina’s trusted supplier since 1997, steps in as a reliable replacement for the Omni Gear RC-61T. Built for tough jobs, this 100 HP gearbox runs at a 1:1 ratio with 1 3/8" 6-spline input and output shafts. It’s designed as a splitter box, perfect for rotary cutters and mowers that need to divide power to outer right-angle gearboxes. If you’re running a 10-foot mower with dual decks—common in Argentina’s sprawling fields—this could be the fit you’re looking for. With TEBSA’s 100% quality guarantee and a 50% cost edge over original brands, it’s a practical choice for heavy-duty cutting.

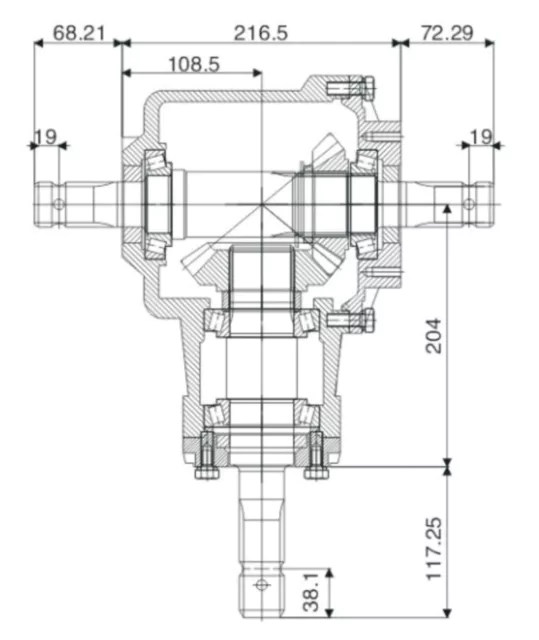

Specifications of RC61T Rotary Cutter Gearbox

- Model: RC-61T

- Ratio: 1:1

- Input: 1 3/8" 6 Spline

- Output: 1 3/8" 6 Spline

- Weight: 70.0 lbs.

- Mounting: 4 bolt, 3 1/4" x 5 pattern

| ITEM | RC61T Rotary Cutter Gearbox |

| Ratio | 1:1 / 1:1.21 / 1:1.46 / 1:1.93 |

| Teeth | 16/16 17/14 19/13 27/14 |

| Module | 7.0 / 7.0 / 7.0 / 5.5 |

| Power (HP) | 60 |

| Rated Input | 540rpm |

| Input/Output Description | 1 3/8 Z6 1 3/8 Z6 Spline Shaft |

| Weight (N.W) | 33.5Kg |

RC61T Rotary Cutter Gearbox Features

- Offers standard and varied ratios—1:1, 1:1.21, 1:1.46, 1:1.93—all precise for your setup.

- Non-1:1 ratios adjust speed: pinion shaft input slows the cross shaft; cross shaft input boosts the pinion.

- Spiral bevel gears deliver smooth power, low noise, minimal vibration, and serious load strength.

- Option for dual input shafts if needed.

- Multiple output shaft choices available.

- Mounts in any position for flexibility.

The Main Purpose of RC61T 100 HP Rotary Cutter Gearbox

- Agriculture and Food

- Building Construction

- Forest and Paper

- Metal Processing

- Chemical and Environmental Protection

Rotary Cutter Gearbox Technical Data

|

Housing Material

|

Cast Iron/Ductile Iron

|

|

Housing Hardness

|

HBS190-240

|

|

Gear Material

|

20CrMnTi Alloy Steel

|

|

Surface Hardness of Gears

|

HRC58~62

|

|

Gear Core Hardness

|

HRC33~40

|

|

Input / Output Shaft Material

|

42CrMo Alloy Steel

|

|

Input / Output Shaft Hardness

|

HRC25~30

|

|

Machining Precision of Gears

|

Accurate Grinding, 6~5 Grade

|

|

Lubricating Oil

|

GB L-CKC220-460, Shell Omala220-460

|

|

Heat Treatment

|

Tempering, Cementing, Quenching, etc.

|

|

Efficiency

|

98%

|

|

Noise (MAX)

|

60~68dB

|

|

Vibration

|

≤20µm

|

|

Backlash

|

≤20Arcmin

|

|

Brand of Bearings

|

China Top Brand Bearing, HRB/LYC/ZWZ/C&U. Or SKF, FAG, INA, NSK on Request

|

|

Brand of Oil Seal

|

NAK — Taiwan or Other Brands on Request

|

Why the RC61T Stands Out for Heavy-Duty Jobs

The RC61T rotary cutter gearbox isn’t just another piece of equipment—it’s a workhorse built for real-world demands. Whether you’re clearing overgrown pastures in Argentina’s Pampas or prepping construction sites near Buenos Aires, this splitter box handles the load. Its 100 HP capacity powers through thick brush or tough crops like soybean and wheat, splitting PTO power evenly to dual mower decks. That’s a big deal for 10-foot cutters, where balance matters.

What sets it apart? The spiral bevel gears. They’re cut from 20CrMnTi alloy steel, hardened to HRC58-62 on the surface, and keep a quieter hum—60 to 68 decibels max—than clunky alternatives. Vibration stays low too, under 20 micrometers, so your machine doesn’t shake itself apart over time. Add in a 98% efficiency rating, and you’re getting nearly all the power you put in, delivered where it counts.

Flexibility’s another perk. With ratio options from 1:1 to 1:1.93, you can tweak it for speed or torque depending on the job—say, slower for heavy forest clearing or faster for light lawn work. The 1 3/8" 6-spline shafts, forged from 42CrMo alloy steel, hook up easily to standard PTOs across Argentina’s farms. And if you need a custom setup? Dual inputs or extra outputs are on the table.

Applications and Benefits Across Industries

This gearbox shines in more than just farming. In agriculture, it’s a go-to for rotary cutters slicing through Argentina’s cornfields or maintaining pastures in Córdoba. Construction crews use it to clear land fast—think rough plots near Rosario. Forestry teams rely on it for shredding branches, while metal shops and chemical plants tap it for auxiliary machinery. It’s versatile enough to handle food processing too, like powering mixers or conveyors.

The benefits stack up quick. First, durability: the cast iron housing, hardened to HBS190-240, takes a beating from rocks or debris. Second, cost: TEBSA’s 50% savings over big-name brands means you’re not overpaying for the same grunt. Third, uptime—our team’s 24-hour response keeps you running if something goes off track. Pair it with proper oil (like Shell Omala 220-460), and you’ve got a gearbox that lasts.

Here’s a quick look at how it fits different tasks:

| Industry | Use Case | Key Advantage |

| Agriculture | Cutting soybean fields | Even power split for dual decks |

| Construction | Site clearing | High torque at 540 RPM |

| Forestry | Branch shredding | Low noise and vibration |

Keeping Your RC61T Running Strong

A gearbox this solid still needs care. Check the oil level every few months—use GB L-CKC220-460 or equivalent—and swap it out if it’s murky. The 33.5 kg (70 lbs.) frame mounts with a 4-bolt, 3 1/4" x 5" pattern, so make sure it’s snug and aligned. Misalignment chews up gears fast. Grease the spline shafts too; it keeps power flowing smooth from the PTO.

Heat treatment—tempering, cementing, quenching—locks in the alloy steel’s toughness, but don’t skip inspections. Look for cracks or wear on the housing. If you hear grinding or feel extra shake, it’s time to call TEBSA’s crew. We’ll sort it fast. Buyers online often ask, “How long does a rotary cutter gearbox last?” With this care, you’re looking at years, even in Argentina’s dusty plains.

About TEBSA Argentina

Since 1997, TEBSA has been Argentina’s go-to for agricultural gearboxes, proudly part of the HZPT family. Based in the heart of farming country, we’ve spent over two decades perfecting gear like the RC61T—built tough, priced right, and backed by a 100% quality pledge. Our 50% cost advantage comes from smart manufacturing, not shortcuts, using alloy steel, cast iron, and processes like forging and grinding. From fast prototypes to bulk runs, our team delivers, with engineers on call within 24 hours. Whether you’re near Buenos Aires or out in the Pampas, we’re here to keep your machines moving. Reach out today!

About us

We guarantee top-quality products at the best prices in China! Special orders are welcome, and if you’re interested in any of our products, feel free to reach out for more detailed information. We ensure our products are safe, high-quality, and reasonably priced. Please contact us as soon as possible if you’d like to learn more. We’re eager to cooperate with you!

A large portion of our products is exported to Europe and the Americas, with both standard and custom options available. We can manufacture according to your drawings or samples, using standard materials or as per your specific requirements. Choosing us means choosing reliability.

Materials Available

1. Stainless Steel: SS201, SS303, SS304, SS316, SS416, SS420

2. Steel:C45(K1045), C46(K1046),C20

3. Brass:C36000 ( C26800), C37700 ( HPb59), C38500( HPb58), C27200(CuZn37), C28000(CuZn40)

4. Bronze: C51000, C52100, C54400, etc

5. Iron: 1213, 12L14,1215

6. Aluminum: Al6061, Al6063

7.OEM according to your request

Surface Treatment

Annealing, natural canonization, heat treatment, polishing, nickel plating, chrome plating, zinc plating,yellow passivization, gold passivization, satin, Black surface painted etc.

Processing Method

CNC machining, punch,turning, milling, drilling, grinding, broaching, welding and assembly

QC & Certificate

Technicians self-check in production,final-check before package by professional Quality inspector

ISO9001:2008 , ISO14001:2001,ISO/TS 16949:2009

Package & Lead Time

Size: Drawings

Wooden Case/Container and pallet, or as per customized specifications.

15-25days samples. 30-45days offcial order

Port: Shanghai/Ningbo port

Industries We Service