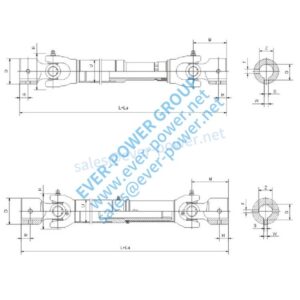

Flexible Drive Shaft

Flexible Drive Shaft: Enhancing Power Transmission Efficiency

The flexible drive shaft is a versatile component that offers a wide range of benefits in power transmission applications. With the ability to overcome misalignment issues, absorb vibrations, and simplify designs, this innovative technology has become a preferred choice in various industries. Whether it's transmitting power around corners or into machines, the flexible drive shaft provides a high degree of freedom in locating drive sources, making it an indispensable solution for many complex drive problems.

A Brief History and Classification of Flexible Drive Shafts

Flexible drive shafts have a rich history that dates back several decades. Originally developed for automotive applications, they have evolved over time to suit various industries and power transmission needs. Today, there are different types of flexible drive shafts available, including:

- Metallic flexible drive shafts

- Rubberized flexible drive shafts

- Polymer-based flexible drive shafts

Each type offers unique advantages and is suitable for specific applications, allowing engineers to tailor their solutions based on the requirements of the project.

Benefits of Using Flexible Drive Shafts

- Misalignment Compensation: Flexible drive shafts excel at compensating for misalignment between the driving and driven elements, ensuring efficient power transmission even in challenging conditions.

- Vibration Dampening: These shafts effectively absorb and isolate vibrations, preventing them from propagating throughout the system and minimizing the risk of damage or performance degradation.

- Simplified Design: By eliminating the need for exposed universal joints, gears, pulleys, or couplings, flexible drive shafts simplify power transmission designs, reduce assembly time, and minimize maintenance requirements.

- Flexible Installation: The freedom in locating drive sources allows for greater flexibility in system design, enabling engineers to optimize space utilization and improve overall performance.

Installation, Maintenance, and Repair

Installing, maintaining, and repairing flexible drive shafts is relatively straightforward. Here are some key guidelines:

- Before installation, ensure that the shaft is clean and free from any debris or contaminants that may affect its performance.

- Follow the manufacturer's instructions regarding proper installation techniques, including torque specifications and alignment procedures.

- Regularly inspect the shaft for signs of wear, such as cracks, fraying, or excessive vibration. Replace the shaft if any abnormalities are detected.

- During maintenance or repair, use compatible lubricants and follow recommended procedures to ensure optimal performance and longevity.

Replace or Upgrade with Confidence

When the time comes to replace or upgrade your existing power transmission system, consider the advantages of flexible drive shafts. With their ability to solve complex drive problems efficiently and economically, these shafts offer a reliable and cost-effective solution. Embrace the benefits of this unique technology and unlock new possibilities for your applications.

Explore Our Range of High-Quality Industrial Products

In addition to flexible drive shafts, our company specializes in supplying various industrial components that are known for their quality and durability. Our wide range of products includes:

- Plastic Gear

- Agricultural Gearboxes

- Power Output Shafts

- Sprockets

- Fluid Couplings

- Worm Gear Reducers

- Gears and Racks

- Detachable Chains

- Pulleys and Pulleys

- Planetary Gearboxes

- Timing Pulleys

- Bushings, and more.

We take pride in our commitment to delivering high-quality products, offering competitive prices, and providing excellent customer service. Whether you need standard components or customized solutions based on your specific requirements, we are here to assist you. Contact us today to discuss your needs and experience the difference of working with a reliable and trusted supplier.

Q&A

1. What are the main advantages of using flexible drive shafts in power transmission?

Flexible drive shafts offer several advantages, including the ability to overcome misalignment, absorb vibrations, simplify designs, and provide flexibility in locating drive sources.

2. Can flexible drive shafts be used in applications with sudden load changes?

Absolutely. Flexible drive shafts can withstand the shock of sudden load changes caused by starting and stopping, making them suitable for dynamic power transmission scenarios.

3. What materials are commonly used for flexible drive shafts?

Flexible drive shafts can be made from various materials, including metallic alloys, rubberized compounds, and polymer-based composites. The choice of material depends on the specific application requirements.

4. How should flexible drive shafts be installed and maintained?

During installation, it is important to follow the manufacturer's instructions for proper alignment, torque specifications, and cleanliness. Regular maintenance involves inspecting the shaft for wear and using compatible lubricants. Any detected abnormalities should prompt replacement.

5. Can flexible drive shafts be customized to meet specific project requirements?

Yes, our company offers customized solutions based on specific project requirements. Contact us with your needs, and our team will work with you to find the best flexible drive shaft solution for your application.

About us

We guarantee top-quality products at the best prices in China! Special orders are welcome, and if you’re interested in any of our products, feel free to reach out for more detailed information. We ensure our products are safe, high-quality, and reasonably priced. Please contact us as soon as possible if you’d like to learn more. We’re eager to cooperate with you!

A large portion of our products is exported to Europe and the Americas, with both standard and custom options available. We can manufacture according to your drawings or samples, using standard materials or as per your specific requirements. Choosing us means choosing reliability.

Materials Available

1. Stainless Steel: SS201, SS303, SS304, SS316, SS416, SS420

2. Steel:C45(K1045), C46(K1046),C20

3. Brass:C36000 ( C26800), C37700 ( HPb59), C38500( HPb58), C27200(CuZn37), C28000(CuZn40)

4. Bronze: C51000, C52100, C54400, etc

5. Iron: 1213, 12L14,1215

6. Aluminum: Al6061, Al6063

7.OEM according to your request

Surface Treatment

Annealing, natural canonization, heat treatment, polishing, nickel plating, chrome plating, zinc plating,yellow passivization, gold passivization, satin, Black surface painted etc.

Processing Method

CNC machining, punch,turning, milling, drilling, grinding, broaching, welding and assembly

QC & Certificate

Technicians self-check in production,final-check before package by professional Quality inspector

ISO9001:2008 , ISO14001:2001,ISO/TS 16949:2009

Package & Lead Time

Size: Drawings

Wooden Case/Container and pallet, or as per customized specifications.

15-25days samples. 30-45days offcial order

Port: Shanghai/Ningbo port

Industries We Service