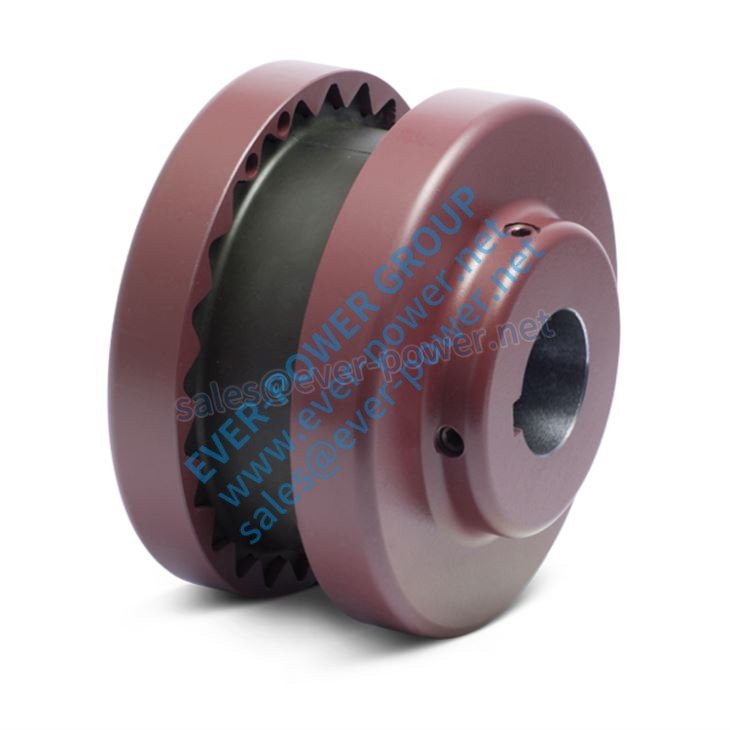

Flexible Flange Coupling

Flexible Flange Coupling: A Versatile Solution for Industrial Applications

A flexible flange coupling is an essential component used in various industrial systems to connect two shafts and transmit torque while accommodating misalignment and shock. With its unique design and flexibility, this coupling offers a reliable and efficient solution for a wide range of applications across industries.

The Evolution of Flexible Flange Couplings

The history of flexible flange couplings dates back to the early days of industrialization when the need for smooth power transmission became crucial. Over time, advancements in technology and engineering have led to the development of various types and designs of flange couplings to suit different requirements.

Classification and Types of Flexible Flange Couplings

- Elastomeric Couplings: These couplings utilize elastomeric elements, such as rubber or polyurethane, to absorb shocks and vibrations.

- Diaphragm Couplings: Diaphragm couplings employ thin metal sheets to transmit torque while compensating for misalignment.

- Gear Couplings: Gear couplings consist of external teeth that engage with each other, providing high torque transmission capabilities.

Advantages of Flexible Flange Couplings

- Compensation for Misalignment: Flexible flange couplings can effectively handle angular, parallel, and axial misalignment, reducing stress on connected machinery.

- Shock and Vibration Absorption: These couplings dampen shocks and vibrations, protecting connected equipment and ensuring smooth operation.

- Torque Transmission: With their robust design, flexible flange couplings offer reliable torque transmission, even in demanding applications.

- Easy Installation and Maintenance: The simplicity of installation and maintenance makes these couplings highly convenient for operators.

- Durable and Long-Lasting: Manufactured from high-quality materials, flexible flange couplings exhibit excellent durability and longevity in various operating conditions.

Materials Used in Flexible Flange Couplings

Flexible flange couplings can be constructed using different materials, depending on the specific application requirements. Some common materials include:

- Steel: Steel couplings provide high strength and resistance to wear, making them suitable for heavy-duty applications.

- Aluminum: Aluminum couplings offer lightweight characteristics, ideal for applications that require reduced inertia.

- Stainless Steel: Stainless steel couplings provide corrosion resistance and are suitable for use in harsh environments.

- Composite Materials: Couplings made from composite materials offer excellent flexibility and chemical resistance.

Installation, Maintenance, and Repair

Installing, maintaining, and repairing a flexible flange coupling can be done with proper care and attention. Here are some key points to consider:

- Installation: Ensure accurate alignment of shafts, proper lubrication, and secure fastening of bolts.

- Maintenance: Regularly inspect the coupling for wear, check for proper lubrication, and address any signs of damage or misalignment promptly.

- Repair: In case of damage or failure, consult the manufacturer's guidelines for specific repair procedures or consider seeking professional assistance.

- Replacement: When a coupling reaches the end of its service life or needs to be replaced, follow the manufacturer's recommendations for suitable replacements and installation procedures.

Explore Our Range of High-Quality Industrial Products

In addition to flexible flange couplings, our company offers a comprehensive range of premium industrial components to cater to diverse needs. Our products include:

- Plastic Gears for Agricultural Gearboxes

- Power Output Shafts

- Sprockets for Industrial Applications

- Fluid Couplings for Efficient Power Transmission

- Worm Gear Reducers for Precise Motion Control

- Gears and Racks for Smooth Power Transfer

- Detachable Chains for Easy Maintenance

- Pulleys and Pulleys for Belt Driven Systems

- Planetary Gearboxes for Versatile Applications

- Timing Pulleys for Synchronized Power Transmission

- Bushings for Shaft Connection

- And much more.

We pride ourselves in offering high-quality products at competitive prices, accompanied by exceptional customer service. Whether you require standard components or customized solutions, we are committed to meeting your unique requirements. Contact us today to explore our extensive product catalog or discuss your specific needs.

Frequently Asked Questions (FAQs)

1. Can a flexible flange coupling accommodate both parallel and angular misalignment?

Yes, flexible flange couplings are designed to handle both parallel and angular misalignment, ensuring smooth power transmission even in challenging conditions.

2. How often should I inspect and maintain a flexible flange coupling?

Regular inspections and maintenance are recommended to ensure optimal performance. Depending on the operating conditions, it is advisable to inspect the coupling at least once every six months.

3. Can I replace a damaged flexible flange coupling on my own?

Replacing a damaged coupling should be done with proper knowledge and expertise. It is recommended to consult the manufacturer's guidelines or seek professional assistance for safe and reliable replacement.

4. What are the advantages of using composite material couplings?

Composite material couplings offer excellent flexibility, chemical resistance, and reduced weight without compromising on strength. They are ideal for applications where weight reduction and corrosion resistance are critical factors.

5. Can you provide customized solutions for specific application requirements?

Absolutely! We specialize in providing customized solutions to meet unique application needs. Our experienced team can work closely with you to design and manufacture couplings tailored to your specific requirements.

About us

We guarantee top-quality products at the best prices in China! Special orders are welcome, and if you’re interested in any of our products, feel free to reach out for more detailed information. We ensure our products are safe, high-quality, and reasonably priced. Please contact us as soon as possible if you’d like to learn more. We’re eager to cooperate with you!

A large portion of our products is exported to Europe and the Americas, with both standard and custom options available. We can manufacture according to your drawings or samples, using standard materials or as per your specific requirements. Choosing us means choosing reliability.

Materials Available

1. Stainless Steel: SS201, SS303, SS304, SS316, SS416, SS420

2. Steel:C45(K1045), C46(K1046),C20

3. Brass:C36000 ( C26800), C37700 ( HPb59), C38500( HPb58), C27200(CuZn37), C28000(CuZn40)

4. Bronze: C51000, C52100, C54400, etc

5. Iron: 1213, 12L14,1215

6. Aluminum: Al6061, Al6063

7.OEM according to your request

Surface Treatment

Annealing, natural canonization, heat treatment, polishing, nickel plating, chrome plating, zinc plating,yellow passivization, gold passivization, satin, Black surface painted etc.

Processing Method

CNC machining, punch,turning, milling, drilling, grinding, broaching, welding and assembly

QC & Certificate

Technicians self-check in production,final-check before package by professional Quality inspector

ISO9001:2008 , ISO14001:2001,ISO/TS 16949:2009

Package & Lead Time

Size: Drawings

Wooden Case/Container and pallet, or as per customized specifications.

15-25days samples. 30-45days offcial order

Port: Shanghai/Ningbo port

Industries We Service