Hydraulic Cutter Gearbox – Replacement of Comer Code A-640A

The Hydraulic Cutter Gearbox A-640A, engineered by TEBSA in Argentina, is a robust power transmission component designed to drive the cutting blades of hydraulic cutters. This gearbox transforms hydraulic energy into rotational force, delivering reliable performance for heavy-duty cutting tasks. Built with precision gears and bearings, it handles high torque levels while ensuring smooth operation. Since 1997, TEBSA has been a trusted manufacturer, offering a 100% quality guarantee and a 50% cost advantage over original brands, making the A-640A a top choice for industries like agriculture, construction, and mining across Argentina.

Ideal for cutting through tough materials like dense crops, woody vegetation, or construction debris, the A-640A is a cornerstone of heavy machinery in Argentina’s Pampas plains and beyond. Its durable construction, using alloy steel and advanced forging techniques, ensures longevity even in harsh conditions. Whether you’re clearing soybean fields in Córdoba or managing pastureland in Buenos Aires, this gearbox delivers efficiency and durability, backed by TEBSA’s 24-hour engineering support.

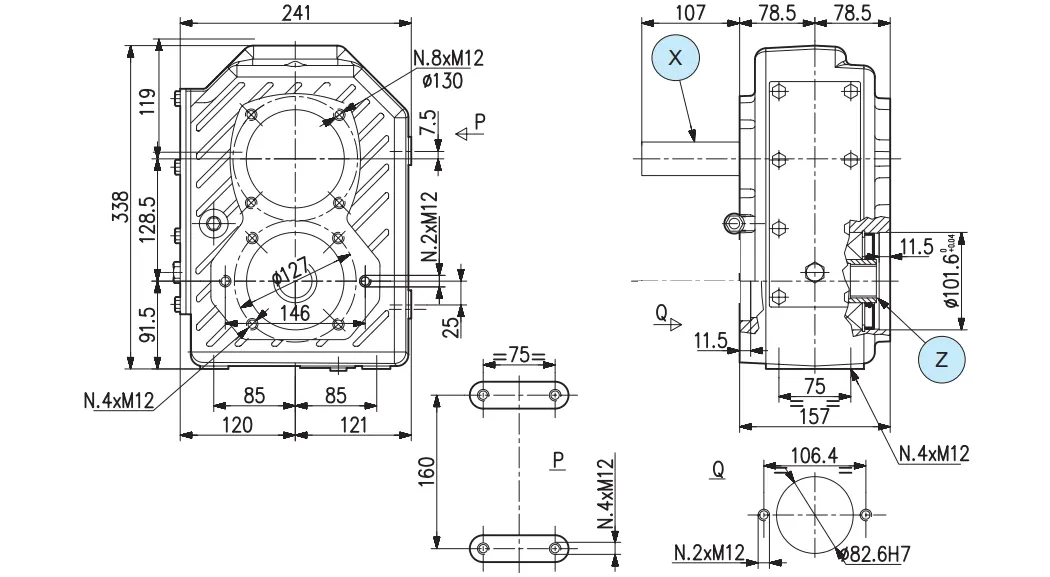

Hydraulic Cutter Gearbox A-640A Specifications

| i | 3.82 |

| N1[rpm] | 540 |

| P1[kW] | 55.9 |

| M2[Nm] | 252 |

Shaft X |

1'' 3/8 Z6 |

Shaft Z |

16/32'' DP Z13 |

| Input | X |

Key Features and Benefits of the A-640A Hydraulic Cutter Gearbox

The A-640A gearbox is a standout solution for heavy-duty cutting, offering a range of advantages tailored to Argentina’s agricultural and industrial needs.

High Torque Capacity: With a torque output of 252 Nm, the A-640A powers through tough materials like hardwood, thick grasses, or construction rubble. Its 3.82 gear ratio ensures optimal blade speed for efficient cutting.

Durable Materials: Constructed from alloy steel with carburization and nitridation heat treatments, this gearbox resists wear and corrosion, even in Argentina’s humid subtropical climates. The housing undergoes blackening and phosphorization for added protection.

Smooth Power Delivery: Precision-engineered gears and tapered roller bearings reduce friction and vibration, ensuring consistent blade rotation. This minimizes wear on connected machinery, extending equipment life.

Versatile Applications: From agricultural tasks like clearing maize fields to mining operations in San Juan, the A-640A adapts to diverse industries. Its 540 rpm input and 55.9 kW power rating suit a wide range of hydraulic cutters.

Cost Efficiency: TEBSA’s strategic manufacturing delivers a 50% cost saving compared to original equipment, making the A-640A an affordable upgrade for farmers and contractors.

Easy Maintenance: Designed with accessible components, the gearbox allows straightforward oil changes and seal replacements, supported by TEBSA’s 24-hour technical team in Argentina.

| Feature | Benefit |

| Alloy Steel Construction | Withstands harsh Argentine farming conditions |

| High Torque (252 Nm) | Powers through dense crops like soybean |

| Tapered Roller Bearings | Ensures smooth, low-vibration operation |

| 50% Cost Advantage | Affordable for small and large farms |

Applications of the A-640A in Argentine Industries

The A-640A hydraulic cutter gearbox excels in Argentina’s diverse industrial landscape, particularly in agriculture, construction, and mining. Its robust design and high torque make it a go-to component for demanding tasks.

- Agriculture: In Argentina’s breadbasket regions like the Pampas, the A-640A drives cutters clearing soybean, wheat, and maize fields. It handles dense vegetation and crop residue, boosting productivity for farmers in Rosario or Santa Fe. The gearbox’s compatibility with tractor-driven hydraulic systems ensures seamless integration with local equipment.

- Construction: For site preparation in Buenos Aires or Córdoba, the A-640A powers cutters slicing through roots, shrubs, and debris. Its durability suits the rugged demands of urban and rural construction projects.

- Mining: In San Juan’s mining hubs, the gearbox supports cutters breaking through tough overburden or rocky terrain. Its alloy steel build and heat-treated gears endure the abrasive conditions of open-pit operations.

The A-640A’s 1'' 3/8 Z6 input shaft and 16/32'' DP Z13 output shaft ensure compatibility with standard hydraulic cutters, making it a versatile choice for buyers searching for “hydraulic cutter gearbox for sale in Argentina” or “reliable agricultural gearbox supplier.”

Maintenance and Longevity Tips for the A-640A

To keep the A-640A performing at its best, TEBSA recommends regular maintenance, leveraging our ISO9001-2015 certified processes for quality assurance.

Oil Checks: Inspect lubricant levels every 50 hours of operation, using manufacturer-approved high-viscosity oil to maintain gear performance. Change oil every 500 hours or annually.

Visual Inspections: Look for signs of leaks, cracks, or wear on the housing monthly. Early detection prevents costly downtime in busy harvest seasons.

Bearing and Seal Care: Clean and regrease the input shaft periodically to ensure efficient power transfer. Replace seals as needed to prevent contamination.

Alignment: Ensure the gearbox and cutter are properly aligned to avoid uneven wear. Misalignment can cause excessive heat and gear damage.

Storage: When not in use, store the gearbox in a dry, covered area to protect against Argentina’s humid weather, especially in coastal regions like Mar del Plata.

By following these steps, farmers and operators in Argentina can maximize the A-640A’s lifespan, minimizing repair costs and maintaining peak efficiency for tasks like “hydraulic cutter gearbox for soybean harvesting.”

About TEBSA and Our Agricultural Gearbox Range

Since 1997, TEBSA has been a leading manufacturer in Argentina, delivering high-performance agricultural gearboxes with a 100% quality guarantee. Based in Argentina, we combine advanced manufacturing—forging, casting, and heat treatments like carbonitriding—with a talented engineering team that responds within 24 hours. Our ISO9001-2015 certification underscores our commitment to excellence, while our 50% cost advantage makes us a trusted partner for farmers and industrial operators across Buenos Aires, Córdoba, and beyond.

In addition to the A-640A hydraulic cutter gearbox, TEBSA offers a wide range of agricultural solutions, including:

- Rotary Cutter Gearboxes: Like the RC-61, ideal for heavy-duty mowing.

- Fertilizer Spreader Gearboxes: For precise nutrient distribution in soybean and wheat fields.

- Post Hole Digger Gearboxes: For efficient fencing and planting in Argentina’s Pampas.

- Flail Mower Gearboxes: For versatile vegetation management.

- PTO Shafts: Durable power transfer for various farm implements.

Whether you’re searching for “agricultural gearbox manufacturer in Argentina” or “buy hydraulic cutter gearbox online,” TEBSA delivers reliable, cost-effective solutions tailored to your needs. Contact us today to explore our full catalog or request a quote!

About us

We guarantee top-quality products at the best prices in China! Special orders are welcome, and if you’re interested in any of our products, feel free to reach out for more detailed information. We ensure our products are safe, high-quality, and reasonably priced. Please contact us as soon as possible if you’d like to learn more. We’re eager to cooperate with you!

A large portion of our products is exported to Europe and the Americas, with both standard and custom options available. We can manufacture according to your drawings or samples, using standard materials or as per your specific requirements. Choosing us means choosing reliability.

Materials Available

1. Stainless Steel: SS201, SS303, SS304, SS316, SS416, SS420

2. Steel:C45(K1045), C46(K1046),C20

3. Brass:C36000 ( C26800), C37700 ( HPb59), C38500( HPb58), C27200(CuZn37), C28000(CuZn40)

4. Bronze: C51000, C52100, C54400, etc

5. Iron: 1213, 12L14,1215

6. Aluminum: Al6061, Al6063

7.OEM according to your request

Surface Treatment

Annealing, natural canonization, heat treatment, polishing, nickel plating, chrome plating, zinc plating,yellow passivization, gold passivization, satin, Black surface painted etc.

Processing Method

CNC machining, punch,turning, milling, drilling, grinding, broaching, welding and assembly

QC & Certificate

Technicians self-check in production,final-check before package by professional Quality inspector

ISO9001:2008 , ISO14001:2001,ISO/TS 16949:2009

Package & Lead Time

Size: Drawings

Wooden Case/Container and pallet, or as per customized specifications.

15-25days samples. 30-45days offcial order

Port: Shanghai/Ningbo port

Industries We Service