Hydraulic Cutter Gearbox – Replacement of Comer Code A-649A

The Hydraulic Cutter Gearbox A-649A, engineered by TEBSA in Argentina, is a vital component for hydraulic cutting machines tackling tough materials like metal, concrete, and wood. Since 1997, TEBSA has delivered reliable, high-quality gearboxes with a 100% quality guarantee, making the A-649A a trusted choice for demanding applications. This gearbox transfers power from the hydraulic motor to the cutting tool, using precision gears, bearings, and seals to reduce speed and boost torque. Built for durability, it withstands the intense stresses of cutting while offering a 50% cost advantage over original brands.

Designed for heavy-duty tasks, the A-649A thrives in industries like construction, forestry, and recycling across Argentina’s diverse landscapes, from Buenos Aires to the Andean foothills. Its robust construction, featuring alloy steel and advanced heat treatments like carburization, ensures long-lasting performance. Regular maintenance and proper lubrication keep it running smoothly, extending its lifespan for years of dependable service.

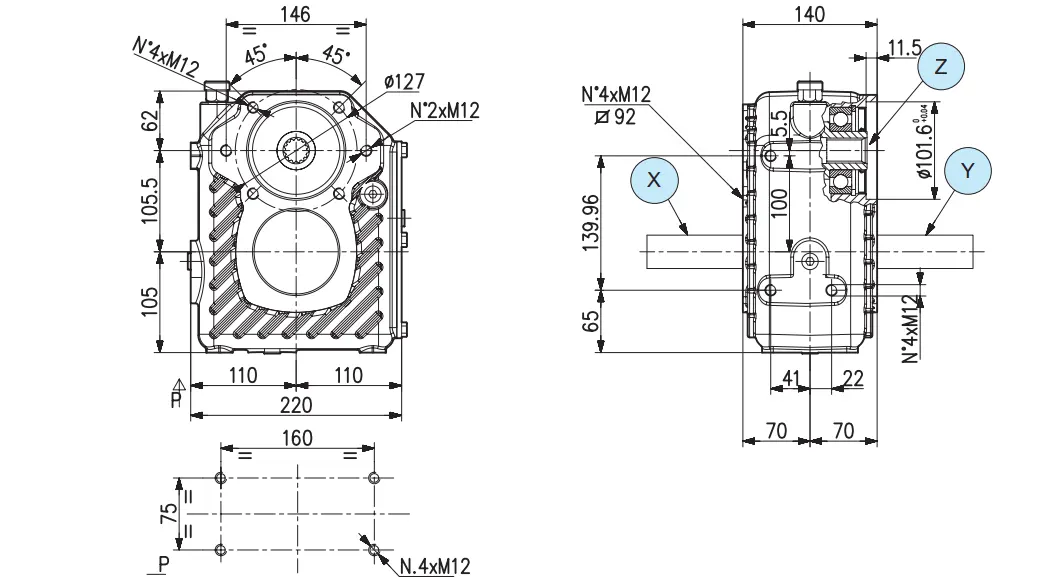

Specifications of the Hydraulic Cutter Gearbox A-649A

| i | 4.23/3.00 |

| N1[rpm] | 540 |

| P1[kW] | 40.4/44.0 |

| M2[Nm] | 172/265 |

Shaft X |

1'' 3/8 Z6 |

Shaft Z |

16/32'' DP Z13 16/32'' DP Z15 |

| Input | X |

Key Features and Benefits of the A-649A Gearbox

The A-649A hydraulic cutter gearbox from TEBSA is designed to deliver top performance in Argentina’s toughest industries. Here’s why it stands out:

High Torque Output: With torque ratings of 172-265 Nm, the A-649A powers through metal, concrete, and wood with ease, making it ideal for heavy-duty cutting in construction sites or recycling plants.

Durable Construction: Made with alloy steel and processed through advanced techniques like forging and carburization, this gearbox resists wear and tear, even in Argentina’s demanding environments like Mendoza’s rocky terrains.

Versatile Gear Ratios: Offering gear ratios of 4.23 and 3.00, it adapts to various cutting speeds, ensuring optimal performance for tasks from forestry in Patagonia to demolition in Buenos Aires.

Reliable Sealing: High-quality seals protect internal components from dust, debris, and hydraulic fluid leaks, ensuring consistent operation in harsh conditions.

Easy Maintenance: Designed for straightforward upkeep, the A-649A allows quick access to seals and bearings, with TEBSA’s engineering team ready to assist within 24 hours.

Cost Savings: At 50% less than comparable original models, it delivers premium performance without breaking the budget, a key advantage for Argentine businesses.

| Feature | Details |

| Material | Alloy Steel with Carburization |

| Torque Range | 172-265 Nm |

| Gear Ratios | 4.23, 3.00 |

| Applications | Construction, Forestry, Recycling |

Applications of the A-649A Hydraulic Cutter Gearbox in Argentina

The A-649A is a versatile powerhouse suited for multiple industries across Argentina. Its ability to handle high-stress cutting makes it indispensable for:

- Construction: Cutting concrete and rebar for infrastructure projects in cities like Córdoba or Rosario, where urban development is booming.

- Forestry: Processing timber in Patagonia’s dense forests, where durability against wood’s toughness is critical.

- Recycling: Shredding metal and other materials in recycling facilities, supporting Argentina’s growing sustainability efforts.

- Industrial Demolition: Breaking down structures with precision, ideal for renovation projects in Buenos Aires.

This gearbox pairs with hydraulic cutting machines to deliver consistent power, whether you’re working on a soybean farm in the Pampas or a construction site in Mendoza. Its adaptability across materials—metal, concrete, wood—makes it a go-to solution for Argentine professionals.

For optimal performance, pair the A-649A with TEBSA’s hydraulic motors and cutting tools. Regular lubrication with manufacturer-approved oils and periodic checks for seal integrity ensure it keeps up with Argentina’s demanding workloads. Whether you’re a contractor, forester, or recycler, the A-649A boosts efficiency and cuts downtime.

| Industry | Material | Region |

| Construction | Concrete, Rebar | Córdoba, Rosario |

| Forestry | Wood | Patagonia |

| Recycling | Metal | Buenos Aires |

Maintenance and Care for Long-Lasting Performance

To keep the A-649A hydraulic cutter gearbox performing at its best, follow these maintenance tips:

Regular Inspections: Check for leaks, worn bearings, or gear damage every 100 hours of use to catch issues early.

Lubrication: Use high-viscosity, manufacturer-approved hydraulic oils, replacing them per TEBSA’s guidelines to prevent friction and overheating.

Seal Checks: Inspect seals for wear, especially in dusty or wet conditions like Argentina’s humid Pampas or dry Andean regions.

Alignment: Ensure the gearbox aligns properly with the motor and cutting tool to avoid uneven stress and prolong gear life.

Cleaning: Remove debris from the gearbox housing after use in muddy or dusty sites to maintain cooling efficiency.

TEBSA’s engineering team, known for responding within 24 hours, can guide you through maintenance or supply replacement parts like seals and bearings. Proper care reduces downtime and keeps your hydraulic cutting machine running smoothly, whether you’re cutting concrete in Rosario or timber in Patagonia.

For businesses buying online, search for “hydraulic cutter gearbox A-649A in Argentina” or “durable gearbox for concrete cutting” to find TEBSA’s solutions. Our 50% cost advantage and ISO9001-2015 certification ensure you get premium quality at a budget-friendly price.

About TEBSA and Our Agricultural and Industrial Solutions

Since 1997, TEBSA has been a leading manufacturer in Argentina, delivering high-performance gearboxes and components with a 100% quality guarantee. Based in Argentina, we combine advanced manufacturing—forging, carburization, and precision grinding—with a 50% cost advantage over original brands. Our ISO9001-2015 certification and 24-hour response team make us a trusted partner for businesses nationwide, from Buenos Aires to Mendoza.

Beyond the A-649A hydraulic cutter gearbox, TEBSA offers a wide range of products for agricultural and industrial needs:

- Rotary Cutter Gearboxes: Like the RC-61, ideal for mowers and heavy-duty cutting.

- Fertilizer Spreader Gearboxes: For precise nutrient distribution in soybean and wheat fields.

- Lawn Mower Gearboxes: Durable solutions for landscaping and pasture management.

- PTO Shafts: Reliable power transfer for tractors and implements across Argentina.

- Flail Mower Gearboxes: Perfect for tough vegetation clearing in the Pampas.

Whether you’re a farmer, contractor, or industrial operator, TEBSA’s solutions are built to last. Contact us today to explore our full range or request a quote for the A-649A hydraulic cutter gearbox. With TEBSA, you’re choosing reliability, efficiency, and unmatched value for Argentina’s toughest jobs.

About us

We guarantee top-quality products at the best prices in China! Special orders are welcome, and if you’re interested in any of our products, feel free to reach out for more detailed information. We ensure our products are safe, high-quality, and reasonably priced. Please contact us as soon as possible if you’d like to learn more. We’re eager to cooperate with you!

A large portion of our products is exported to Europe and the Americas, with both standard and custom options available. We can manufacture according to your drawings or samples, using standard materials or as per your specific requirements. Choosing us means choosing reliability.

Materials Available

1. Stainless Steel: SS201, SS303, SS304, SS316, SS416, SS420

2. Steel:C45(K1045), C46(K1046),C20

3. Brass:C36000 ( C26800), C37700 ( HPb59), C38500( HPb58), C27200(CuZn37), C28000(CuZn40)

4. Bronze: C51000, C52100, C54400, etc

5. Iron: 1213, 12L14,1215

6. Aluminum: Al6061, Al6063

7.OEM according to your request

Surface Treatment

Annealing, natural canonization, heat treatment, polishing, nickel plating, chrome plating, zinc plating,yellow passivization, gold passivization, satin, Black surface painted etc.

Processing Method

CNC machining, punch,turning, milling, drilling, grinding, broaching, welding and assembly

QC & Certificate

Technicians self-check in production,final-check before package by professional Quality inspector

ISO9001:2008 , ISO14001:2001,ISO/TS 16949:2009

Package & Lead Time

Size: Drawings

Wooden Case/Container and pallet, or as per customized specifications.

15-25days samples. 30-45days offcial order

Port: Shanghai/Ningbo port

Industries We Service