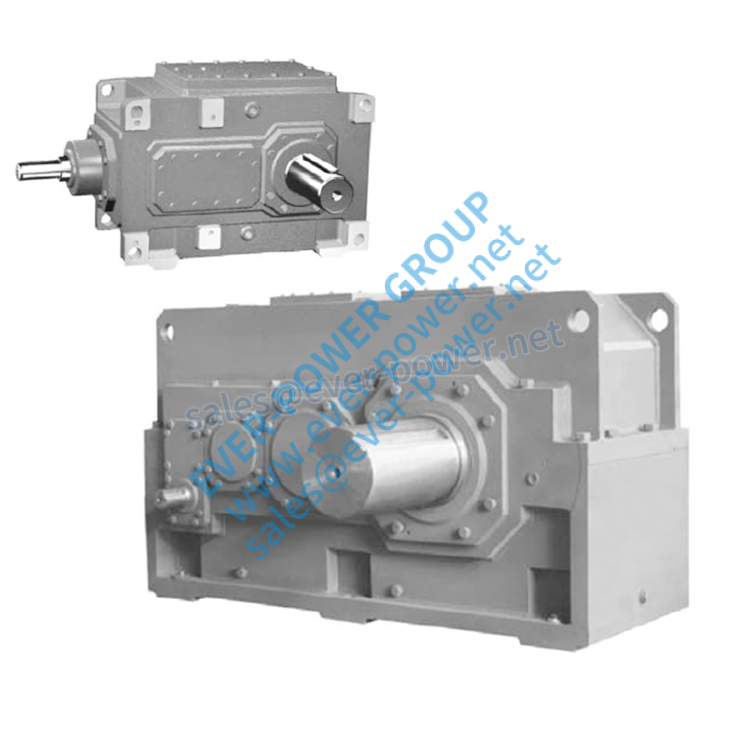

MTH MTB Series high power reductor

MTH MTB Series High Power Reductor: Boosting Performance and Reliability

Are you searching for a high power reductor that can revolutionize your industrial operations? Look no further than the MTH MTB Series. With its exceptional design and innovative features, this reductor is engineered to deliver unparalleled performance and reliability in various applications. Read on to learn more about this remarkable product.

Achieving New Heights in Design and Innovation

- Introducing a completely new design, the MTH MTB Series reductor stands out with its outstanding innovations.

- Experience a wide range of sizes while benefiting from a reduced variety of parts, streamlining your inventory management.

- Enjoy higher operational reliability combined with increased power capacity, ensuring optimal performance in demanding environments.

- Facilitate assembly even in confined spaces with the availability of flanged output shafts (on request).

Versatile Mounting Options

- Choose between horizontal or vertical installation to fit your specific requirements.

- Custom mounting arrangements are also possible upon request, providing flexibility for unique applications.

- Motor bell housings and torque supports are part of our standard product range, simplifying installation and ensuring stability.

Enhanced Noise Reduction

- Experience an improved noise emission with the MTH MTB Series reductor, thanks to innovative design concepts.

- Noise-absorbing housings have been employed to minimize noise levels.

- Achieve exceptionally large contact ratios, further contributing to noise reduction.

Efficient Thermal Conduction

- Not only do MTH MTB Series gear units boast high efficiency, but they also excel in thermal conduction.

- Enlarged housing surface areas ensure improved heat dissipation, enhancing overall performance.

- Employing new types of air conduction fan cowls, larger fans contribute to efficient cooling.

- The selection of gear units is based on a lower maximum oil temperature, resulting in increased operational reliability and reduced maintenance costs due to extended oil change intervals.

Innovative Unit Construction

The MTH MTB Series gear units have been meticulously designed following a new unit construction principle, ensuring durability and ease of maintenance.

Other High-Quality Products by Our Company

At our company, we take pride in offering a broad range of top-notch industrial gear solutions. In addition to the MTH MTB Series, we supply various Plastic Gear products that cater to diverse industry needs:

- Agricultural gearboxes for efficient power transmission in the agricultural sector.

- Power output shafts designed to deliver reliable performance in demanding applications.

- Sprockets for smooth and precise power transmission.

- Fluid couplings for effective torque transfer in fluid power systems.

- Worm gear reducers known for their compact design and high efficiency.

- Gears and racks for precise motion control in various machinery.

- Detachable chains for quick and easy maintenance.

- Pulleys and pulleys to facilitate power transmission and speed regulation.

- Planetary gearboxes for high torque and precise motion control.

- Timing pulleys for accurate timing and synchronization.

- Bushings for smooth and reliable rotational motion.

- And much more!

We are committed to delivering products of the highest quality, offering competitive prices, and providing excellent customer service. We welcome customers to explore our product range, collaborate on customized solutions based on drawings or samples, and discover the unbeatable value we provide.

Q&A

Q1: What makes the MTH MTB Series reductor stand out from other gear units?

A1: The MTH MTB Series reductor boasts a completely new design, offering more sizes with a reduced variety of parts, higher operational reliability, increased power capacity, and the option for flanged output shafts for assembly in confined spaces.

Q2: Can the MTH MTB Series reductor be installed vertically?

A2: Yes, the MTH MTB Series reductor is designed to be supplied for both horizontal and vertical installation, providing flexibility to accommodate different applications.

Q3: How does the MTH MTB Series reductor achieve noise reduction?

A3: The MTH MTB Series reductor employs innovative concepts such as noise-absorbing housings and exceptionally large contact ratios to significantly improve noise emission.

Q4: Does the MTH MTB Series reductor have efficient thermal conduction?

A4: Yes, the MTH MTB Series reductor excels in thermal conduction with enlarged housing surface areas and large fans incorporating a new type of air conduction fan cowl, ensuring optimal heat dissipation.

Q5: Apart from the MTH MTB Series, what other products does your company offer?

A5: In addition to the MTH MTB Series, our company supplies a wide range of high-quality industrial gear products, including agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, detachable chains, pulleys and pulleys, planetary gearboxes, timing pulleys, bushings, and more.

About us

We guarantee top-quality products at the best prices in China! Special orders are welcome, and if you’re interested in any of our products, feel free to reach out for more detailed information. We ensure our products are safe, high-quality, and reasonably priced. Please contact us as soon as possible if you’d like to learn more. We’re eager to cooperate with you!

A large portion of our products is exported to Europe and the Americas, with both standard and custom options available. We can manufacture according to your drawings or samples, using standard materials or as per your specific requirements. Choosing us means choosing reliability.

Materials Available

1. Stainless Steel: SS201, SS303, SS304, SS316, SS416, SS420

2. Steel:C45(K1045), C46(K1046),C20

3. Brass:C36000 ( C26800), C37700 ( HPb59), C38500( HPb58), C27200(CuZn37), C28000(CuZn40)

4. Bronze: C51000, C52100, C54400, etc

5. Iron: 1213, 12L14,1215

6. Aluminum: Al6061, Al6063

7.OEM according to your request

Surface Treatment

Annealing, natural canonization, heat treatment, polishing, nickel plating, chrome plating, zinc plating,yellow passivization, gold passivization, satin, Black surface painted etc.

Processing Method

CNC machining, punch,turning, milling, drilling, grinding, broaching, welding and assembly

QC & Certificate

Technicians self-check in production,final-check before package by professional Quality inspector

ISO9001:2008 , ISO14001:2001,ISO/TS 16949:2009

Package & Lead Time

Size: Drawings

Wooden Case/Container and pallet, or as per customized specifications.

15-25days samples. 30-45days offcial order

Port: Shanghai/Ningbo port

Industries We Service