pto drive shaft 04B 800 YIIIP universal joint for pto shaft agricultural machines part

PTO Drive Shaft 04B 800 YIIIP Universal Joint for PTO Shaft Agricultural Machines Part

The PTO Drive Shaft 04B 800 YIIIP Universal Joint is a high-quality and durable component designed for use in agricultural machines. It is a new product for the year 2020 and is manufactured by EVER-POWER, a trusted brand in the industry. This universal joint is specifically designed for tractors and farm implements, making it an essential part for various farming applications.

Product Specifications:

- Condition: New

- Warranty: 1 year

- Applicable Industries: Farms, Construction works, Energy & Mining

- Weight (KG): 13 KG

- Showroom Location: None

- Video outgoing-inspection: Provided

- Machinery Test Report: Not Available

- Marketing Type: New Product 2020

- Type: Shafts

- Use: Harvesters

- Product Name: 04B 800 YIIIP universal joint for PTO shaft agricultural machines part

- Usage: Tractors and Farm Implements

- Certificate: CE, ISO and TS

- Processing of Tube: Cold-Drawn

- Material: Steel

- Brand: EVER-POWER

- Tubes: Triangle Tubes

- Color: Yellow Spraying

- Length: 800mm

- OEM: OEM Service

- Packaging Details: Plastic bag+ Woodencase + According to Customer's request

- Port: Shanghai or Ningbo

The Structure of PTO Shaft

The PTO Shaft is a crucial component used in various agricultural machines. It is responsible for transmitting power from the source to the driven equipment. EVER-POWER Group Co., Ltd., located in Hangzhou City, is a leading manufacturer and supplier of PTO Shafts and related products. With a strong focus on quality, timely delivery, and competitive pricing, EVER-POWER has gained a great reputation in the global market.

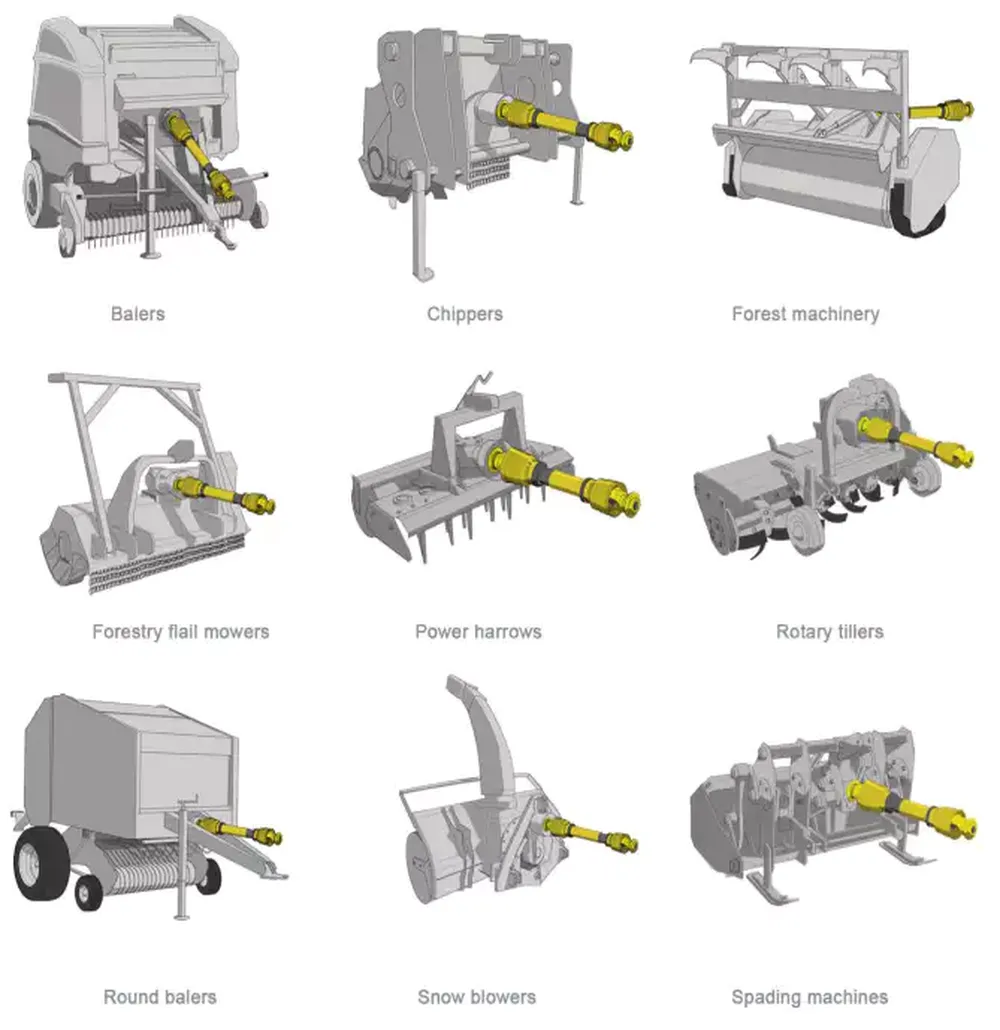

Common Usage Scenarios:

- Harvesting crops

- Tilling soil

- Mowing fields

- Baling hay

- Operating farm implements

History of PTO Shafts:

PTO Shafts have been an integral part of agricultural machinery for many years. Their development can be traced back to the early 20th century when tractors started to become widely used on farms. Over time, advancements in design and technology have led to the development of more efficient and reliable PTO Shafts.

Classification of PTO Shafts:

PTO Shafts can be classified based on various factors, including length, power rating, and attachment mechanism. Different types of PTO Shafts are available to suit the specific needs of different agricultural machines and implements.

Advantages of PTO Shafts:

- High power transmission efficiency

- Reliable and durable

- Easy to install and use

- Compatible with a wide range of farm implements

- Low maintenance requirements

Available Product Materials:

PTO Shafts are typically made of high-quality steel. The use of steel ensures the shaft's strength and durability, allowing it to withstand the demands of agricultural operations.

Installation, Maintenance, and Repair:

Proper installation, maintenance, and repair are essential for the optimal performance and longevity of PTO Shafts. Here are some key considerations:

- Follow the manufacturer's instructions for installation

- Regularly inspect the shaft and its components for wear and damage

- Keep the shaft clean and free from debris

- Grease the joints and bearings as recommended

- Address any issues or damage promptly to prevent further damage

- Refer to the manufacturer's guidelines for repair procedures

Replacement of PTO Shafts:

When replacing a PTO Shaft, it is important to choose a compatible replacement that meets the specifications of the original shaft. Consult the manufacturer or a qualified technician for guidance on selecting and installing the appropriate replacement shaft.

Discover our other products:

We are a leading supplier of various industrial plastic gears, including agricultural gearboxes, power output shafts, sprockets, hydraulic couplings, worm gear reducers, gear racks, removable chains, pulleys and pulleys, planetary gearboxes, timing pulleys, bushings, and more. Our products are of high quality, competitively priced, and backed by excellent customer service. We welcome customization based on your specific requirements and can provide both pictures and samples for your reference.

FAQ

1. Q: Are your products forged or cast?

A: All of our products are forged.

2. Q: Do you have a CE certificate?

A: Yes, we have CE, TS/16949, ISO9001 Certificates.

3. Q: What's the horsepower range of your PTO shafts?

A: We provide a full range of PTO shafts, ranging from 16HP to 200HP.

4. Q: How many splined specifications do you offer?

A: We produce various splined specifications, including 1 1/8"-Z6, 1 3/8"-Z6, 1 3/4"-Z6, 1 3/8"-Z21, 1 3/4"-Z20, 8X42X48X8, and 8X32X38X6 splines.

5. Q: What are your payment terms?

A: We accept T/T, L/C, D/A, D/P, and other payment methods.

Author: lmc

Disclaimer: All content on this page is sourced from the internet and is intended for reference purposes only. Our products are aftermarket accessories and not original spare parts. We are not the holder of the original trademark mentioned in the content. If you require original spare parts, please contact the respective manufacturer for purchasing.

About us

We guarantee top-quality products at the best prices in China! Special orders are welcome, and if you’re interested in any of our products, feel free to reach out for more detailed information. We ensure our products are safe, high-quality, and reasonably priced. Please contact us as soon as possible if you’d like to learn more. We’re eager to cooperate with you!

A large portion of our products is exported to Europe and the Americas, with both standard and custom options available. We can manufacture according to your drawings or samples, using standard materials or as per your specific requirements. Choosing us means choosing reliability.

Materials Available

1. Stainless Steel: SS201, SS303, SS304, SS316, SS416, SS420

2. Steel:C45(K1045), C46(K1046),C20

3. Brass:C36000 ( C26800), C37700 ( HPb59), C38500( HPb58), C27200(CuZn37), C28000(CuZn40)

4. Bronze: C51000, C52100, C54400, etc

5. Iron: 1213, 12L14,1215

6. Aluminum: Al6061, Al6063

7.OEM according to your request

Surface Treatment

Annealing, natural canonization, heat treatment, polishing, nickel plating, chrome plating, zinc plating,yellow passivization, gold passivization, satin, Black surface painted etc.

Processing Method

CNC machining, punch,turning, milling, drilling, grinding, broaching, welding and assembly

QC & Certificate

Technicians self-check in production,final-check before package by professional Quality inspector

ISO9001:2008 , ISO14001:2001,ISO/TS 16949:2009

Package & Lead Time

Size: Drawings

Wooden Case/Container and pallet, or as per customized specifications.

15-25days samples. 30-45days offcial order

Port: Shanghai/Ningbo port

Industries We Service