QD Sprocket No.120 Single Type

QD Sprocket No.120 Single Type

QD Sprocket No.120 Single Type is a type of sprocket that is widely used in power transmission systems. It is designed to transmit torque and power from one rotating shaft to another. QD sprockets are an essential component of many machines, including conveyor systems, pumps, and industrial machinery.

Introduction to QD Sprocket No.120 Single Type

QD Sprocket No.120 Single Type is a highly reliable and efficient sprocket that offers exceptional performance in power transmission systems. It is specifically designed to withstand heavy loads and provide a secure connection between rotating shafts. With its robust construction and precise tooth profiles, QD Sprocket No.120 Single Type ensures smooth and reliable power transmission in various industrial applications.

Common Usage Scenarios

QD Sprocket No.120 Single Type finds its application in a wide range of industries and machinery. Some common usage scenarios include:

- Conveyor Systems: QD Sprocket No.120 Single Type is widely used in conveyor systems to transfer materials efficiently and reliably.

- Pumps: QD Sprocket No.120 Single Type is utilized in pumps to transmit power and drive fluid flow effectively.

- Industrial Machinery: QD Sprocket No.120 Single Type plays a crucial role in various types of industrial machinery, such as mixers, crushers, and compressors.

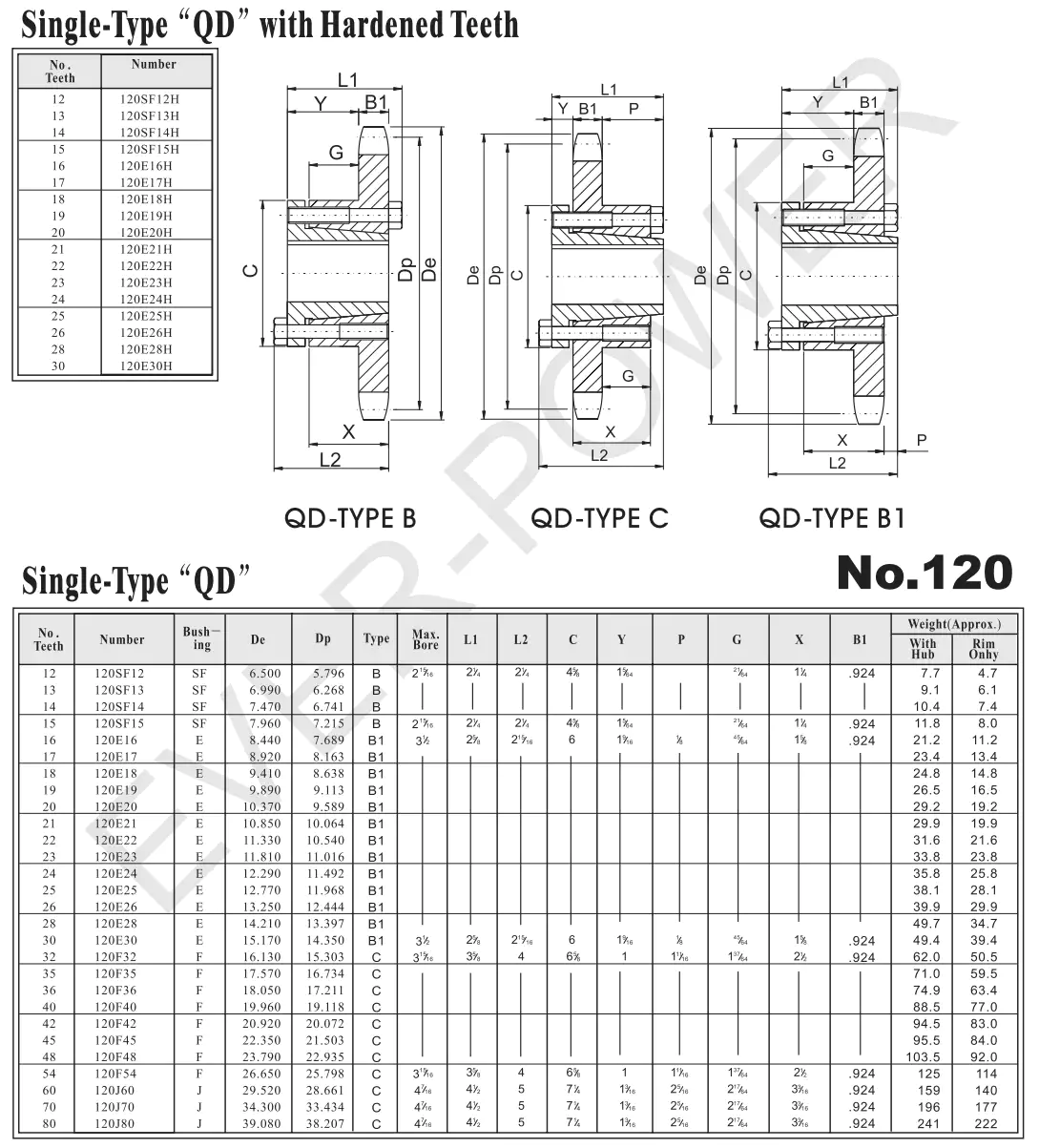

Product History and Classification

QD Sprocket No.120 Single Type has a rich history and has evolved over time to meet the changing needs of industries. It belongs to the QD sprocket family, known for their reliable performance and ease of installation. QD sprockets are classified based on their size, tooth profiles, and material composition, ensuring compatibility with different chain sizes and applications.

Advantages of QD Sprocket No.120 Single Type

- Exceptional Durability: QD Sprocket No.120 Single Type is built to withstand heavy loads and harsh operating conditions, ensuring long-lasting performance.

- Precision Tooth Profiles: The precisely cut tooth profiles of QD Sprocket No.120 Single Type ensure smooth and efficient power transmission, reducing wear and extending chain life.

- Easy Installation and Removal: QD Sprocket No.120 Single Type can be easily installed and removed using basic tools, minimizing downtime and maintenance costs.

- Wide Compatibility: QD Sprocket No.120 Single Type is compatible with a wide range of chain sizes and types, providing flexibility in design and application.

- Low Maintenance: QD Sprocket No.120 Single Type requires minimal maintenance and is designed for reliable, trouble-free operation.

Available Product Materials

QD Sprocket No.120 Single Type is available in various materials, including high-quality steel alloys and heat-treated cast iron. The choice of material depends on the specific application requirements and the desired level of strength and durability.

Installation, Maintenance, and Repair

Installing, maintaining, and repairing QD Sprocket No.120 Single Type is relatively straightforward. Here are the recommended steps:

- Installation:

- Prepare the necessary tools and materials, including a torque wrench, a hammer, and a clean rag.

- Clean the shaft and sprocket surface to remove any dirt or debris.

- Slide the sprocket onto the shaft and position it in the desired location.

- Slide the QD bushing onto the shaft and align it with the sprocket hub. Use a hammer to tap the bushing into place until it is snug against the sprocket hub.

- Tighten the set screws on the QD bushing using a torque wrench to secure the sprocket in place.

- Check the alignment of the sprocket and QD bushing to ensure they are properly installed and aligned.

- Maintenance and Repair:

- Regularly inspect the sprocket and QD bushing for signs of wear, damage, or misalignment.

- If any issues are identified, follow the manufacturer's guidelines for maintenance and repair.

How to Replace QD Sprocket No.120 Single Type

When it becomes necessary to replace QD Sprocket No.120 Single Type, follow these steps:

- Remove the set screws on the QD bushing using a torque wrench.

- Tap the QD bushing using a hammer to loosen it from the sprocket hub.

- Slide the QD bushing off the shaft.

- Replace the old sprocket with a new QD Sprocket No.120 Single Type.

- Follow the installation steps mentioned earlier to install the new sprocket.

FAQ

- Q: What is the maximum torque that QD Sprocket No.120 Single Type can handle?

- A: The maximum torque capacity of QD Sprocket No.120 Single Type depends on its specific size and material composition. Refer to the manufacturer's specifications for detailed information.

- Q: Can QD Sprocket No.120 Single Type be used with different types of chains?

- A: Yes, QD Sprocket No.120 Single Type is designed to be compatible with a wide range of chain sizes and types. Consult the manufacturer's specifications for more information.

- Q: What is the difference between QD Sprocket No.120 Single Type and a Taper-Lock sprocket?

- A: QD Sprocket No.120 Single Type uses a QD bushing to mount the sprocket onto the shaft, while Taper-Lock sprockets use a tapered bore for a secure connection. QD sprockets offer ease of installation and removal, while Taper-Lock sprockets provide enhanced security.

- Q: Can QD Sprocket No.120 Single Type be used in high-speed applications?

- A: QD Sprocket No.120 Single Type can be used in high-speed applications if it is specifically designed and manufactured to meet the required specifications. Refer to the manufacturer's specifications for more information.

Author: lmc

Disclaimer: All the content on this page is sourced from the internet and is intended for reference purposes only. Our products are aftermarket accessories and not original spare parts. We are not the holder of the original trademark. Our accessories are designed to perfectly fit the original spare parts. If you require original spare parts, please contact the original manufacturer for purchasing.

About us

We guarantee top-quality products at the best prices in China! Special orders are welcome, and if you’re interested in any of our products, feel free to reach out for more detailed information. We ensure our products are safe, high-quality, and reasonably priced. Please contact us as soon as possible if you’d like to learn more. We’re eager to cooperate with you!

A large portion of our products is exported to Europe and the Americas, with both standard and custom options available. We can manufacture according to your drawings or samples, using standard materials or as per your specific requirements. Choosing us means choosing reliability.

Materials Available

1. Stainless Steel: SS201, SS303, SS304, SS316, SS416, SS420

2. Steel:C45(K1045), C46(K1046),C20

3. Brass:C36000 ( C26800), C37700 ( HPb59), C38500( HPb58), C27200(CuZn37), C28000(CuZn40)

4. Bronze: C51000, C52100, C54400, etc

5. Iron: 1213, 12L14,1215

6. Aluminum: Al6061, Al6063

7.OEM according to your request

Surface Treatment

Annealing, natural canonization, heat treatment, polishing, nickel plating, chrome plating, zinc plating,yellow passivization, gold passivization, satin, Black surface painted etc.

Processing Method

CNC machining, punch,turning, milling, drilling, grinding, broaching, welding and assembly

QC & Certificate

Technicians self-check in production,final-check before package by professional Quality inspector

ISO9001:2008 , ISO14001:2001,ISO/TS 16949:2009

Package & Lead Time

Size: Drawings

Wooden Case/Container and pallet, or as per customized specifications.

15-25days samples. 30-45days offcial order

Port: Shanghai/Ningbo port

Industries We Service