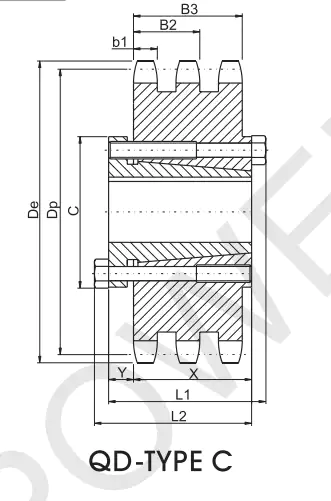

QD Sprocket No.35-3 Triple Type

QD Sprocket No.35-3 Triple Type

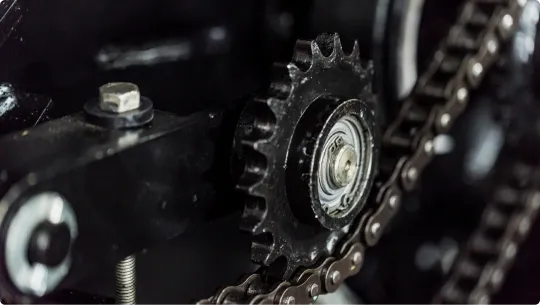

The QD Sprocket No.35-3 Triple Type is a type of sprocket that is commonly used in transmission systems. It plays a crucial role in transferring power from one component to another. QD sprockets are widely used in various industries for their reliable performance and durability.

Introduction

The QD Sprocket No.35-3 Triple Type is a versatile sprocket designed for efficient power transmission in various applications. Its robust construction and reliable performance make it a popular choice in industries such as manufacturing, agriculture, and automotive.

Common Usage Scenarios

The QD Sprocket No.35-3 Triple Type finds its applications in a wide range of equipment and machinery. Some common usage scenarios include:

- Conveyor Systems: The sprocket is used to drive conveyor belts, ensuring smooth movement of materials in industries such as manufacturing and logistics.

- Agricultural Machinery: QD sprockets are essential components in agricultural equipment like combine harvesters and tractors, providing reliable power transmission for tasks such as grain harvesting and field cultivation.

- Industrial Machinery: From heavy-duty machinery to precision equipment, QD sprockets are used in various industrial applications, including printing presses, packaging machines, and material handling systems.

- Construction Equipment: The sprocket is utilized in construction machinery like excavators and bulldozers, enabling efficient movement and operation.

- Power Transmission Systems: QD sprockets play a vital role in power transmission systems, ensuring smooth and reliable transfer of power from motors to other components.

History and Classification

QD sprockets have a long history and have evolved over time to meet the changing needs of industries. They are available in different classifications based on factors such as tooth count, pitch size, and bore size. The No.35-3 Triple Type is specifically designed for applications that require a triple-strand chain.

Advantages of QD Sprocket No.35-3 Triple Type

- High Load Capacity: The QD Sprocket No.35-3 Triple Type is engineered to handle heavy loads, making it suitable for demanding applications.

- Durable Construction: It is made from high-quality materials to ensure long-lasting performance even in harsh operating conditions.

- Easy Installation and Replacement: The Quick Disconnect (QD) bushing system allows for quick and hassle-free installation or replacement of the sprocket.

- Wide Compatibility: The standardized design of QD sprockets ensures compatibility with various chain types, providing flexibility in equipment design and maintenance.

- Efficient Power Transmission: The teeth of the sprocket engage with the links of the chain, ensuring efficient transfer of power from the driving component to the driven component.

- Low Maintenance: QD sprockets require minimal maintenance, reducing downtime and overall maintenance expenses.

Available Product Materials

The QD Sprocket No.35-3 Triple Type is available in different materials to suit specific application requirements. Common materials include:

- Steel: Steel sprockets are widely used for their excellent strength and durability, making them suitable for heavy-duty applications.

- Stainless Steel: Stainless steel sprockets offer resistance to corrosion and high temperatures, making them ideal for industries with demanding environmental conditions.

- Cast Iron: Cast iron sprockets provide good wear resistance and are often used in applications that require high torque transmission.

- Plastic: Plastic sprockets are lightweight and offer low noise operation, making them suitable for applications where reduced weight and noise are important.

Installation and Maintenance

Proper installation and maintenance of the QD Sprocket No.35-3 Triple Type are essential to ensure optimal performance and longevity. Follow these steps for installation:

- Prepare Tools and Materials: Gather the necessary tools and materials for the installation process, including the QD bushing, set screws or locking mechanism, and appropriate wrenches.

- Clean Shaft and Sprocket Surface: Thoroughly clean the shaft and sprocket surface to remove any dirt, debris, or old lubricant.

- Position the Sprocket: Place the sprocket in the desired position on the shaft, ensuring proper alignment with the driven component.

- Install QD Bushing: Align the QD bushing with the sprocket and slide it onto the shaft until it reaches the desired position.

- Secure the Sprocket: Use the provided set screws or locking mechanism to secure the sprocket onto the QD bushing, ensuring a tight and secure fit.

- Check for Proper Installation: Double-check the alignment and tightness of the sprocket and QD bushing to ensure a secure and reliable connection.

Regular maintenance is crucial to keep the QD Sprocket No.35-3 Triple Type in optimal condition. Visual inspections should be performed periodically to identify any signs of wear, damage, or misalignment. Lubrication should be applied as per the manufacturer's recommendations to minimize friction and ensure smooth operation.

Product Replacement

If replacement of the QD Sprocket No.35-3 Triple Type is necessary, follow these steps:

- Prepare Tools and Materials: Gather the necessary tools and materials for the replacement process, including the new sprocket, QD bushing, set screws or locking mechanism, and appropriate wrenches.

- Follow the Removal Process: Follow the steps mentioned earlier for removing the existing sprocket and QD bushing from the shaft.

- Clean Shaft and Sprocket Surface: Thoroughly clean the shaft and sprocket surface to remove any dirt, debris, or old lubricant.

- Install New QD Bushing and Sprocket: Align the new QD bushing with the new sprocket and slide them onto the shaft until they reach the desired position.

- Secure the New Sprocket: Use the provided set screws or locking mechanism to secure the new sprocket onto the QD bushing, ensuring a tight and secure fit.

- Check for Proper Installation: Double-check the alignment and tightness of the new sprocket and QD bushing to ensure a secure and reliable connection.

Manufacturing Process of QD Sprockets

- Raw Material Preparation: Carefully select high-quality materials suitable for the production of QD sprockets, considering factors such as strength and durability.

- Cutting: Utilize precise cutting techniques to shape the raw material into the desired form and size for further processing.

- Forging or Casting: Employ forging or casting methods to enhance the strength and integrity of the sprocket, ensuring it can withstand heavy loads and harsh conditions.

- Machining: Utilize advanced machining techniques to create the teeth and other intricate features of the sprocket, ensuring precise dimensions and smooth operation.

- Tooth Rolling: Implement tooth rolling processes to ensure accurate tooth profiles and proper engagement with the chain, enhancing the overall efficiency of power transmission.

- Heat Treatment: Apply heat treatment methods such as quenching and tempering to optimize the hardness and toughness of the sprocket, improving its resistance to wear and fatigue.

- Surface Treatment: Implement surface treatment techniques such as plating or coating to enhance the sprocket's resistance to corrosion, extending its service life.

- Quality Inspection: Conduct rigorous quality inspections throughout the manufacturing process to ensure that each QD sprocket meets the required standards for dimensional accuracy, material strength, and overall performance.

FAQ - Frequently Asked Questions

- Q: How do I choose the right QD sprocket for my application?

- Q: Can I reuse a QD bushing after removing it?

- Q: Are QD sprockets suitable for high-speed applications?

- Q: Can I install a QD bushing on an existing sprocket?

A: Selecting the appropriate QD sprocket depends on factors such as the desired speed ratio, power requirements, chain specifications, and the specific application. Consulting with a knowledgeable supplier can help you make the right choice.

A: QD bushings are designed for multiple installations and removals. However, it is essential to inspect the bushing for any signs of wear or damage before reusing it to ensure optimal performance and safety.

A: Yes, QD sprockets are designed to withstand high speeds and transmit power efficiently. However, factors such as dynamic balancing and proper lubrication should be considered for optimal performance in high-speed applications.

A: Yes, QD bushings are designed to be compatible with

About us

We guarantee top-quality products at the best prices in China! Special orders are welcome, and if you’re interested in any of our products, feel free to reach out for more detailed information. We ensure our products are safe, high-quality, and reasonably priced. Please contact us as soon as possible if you’d like to learn more. We’re eager to cooperate with you!

A large portion of our products is exported to Europe and the Americas, with both standard and custom options available. We can manufacture according to your drawings or samples, using standard materials or as per your specific requirements. Choosing us means choosing reliability.

Materials Available

1. Stainless Steel: SS201, SS303, SS304, SS316, SS416, SS420

2. Steel:C45(K1045), C46(K1046),C20

3. Brass:C36000 ( C26800), C37700 ( HPb59), C38500( HPb58), C27200(CuZn37), C28000(CuZn40)

4. Bronze: C51000, C52100, C54400, etc

5. Iron: 1213, 12L14,1215

6. Aluminum: Al6061, Al6063

7.OEM according to your request

Surface Treatment

Annealing, natural canonization, heat treatment, polishing, nickel plating, chrome plating, zinc plating,yellow passivization, gold passivization, satin, Black surface painted etc.

Processing Method

CNC machining, punch,turning, milling, drilling, grinding, broaching, welding and assembly

QC & Certificate

Technicians self-check in production,final-check before package by professional Quality inspector

ISO9001:2008 , ISO14001:2001,ISO/TS 16949:2009

Package & Lead Time

Size: Drawings

Wooden Case/Container and pallet, or as per customized specifications.

15-25days samples. 30-45days offcial order

Port: Shanghai/Ningbo port

Industries We Service