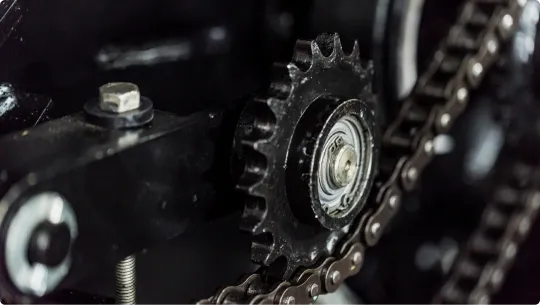

QD Sprocket No.35 Single Type

Introduction to Roller Chain Sprockets

Roller chain sprockets are an essential component in power transmission systems. They are used to transmit power from one rotating shaft to another by means of a chain. Roller chain sprockets are widely used in various industries, such as agriculture, mining, and construction, as they are known for their reliability, durability, and ease of use.

History of Roller Chain Sprockets

The roller chain sprocket was first invented by Hans Renold in 1880. The original design was simple but effective, consisting of a sprocket with teeth that engaged with a roller chain. Over the years, roller chain sprockets have evolved to meet the changing needs of industry, with new materials, designs, and manufacturing processes being developed to improve their performance and reliability.

Types of Roller Chain Sprockets

There are several types of roller chain sprockets, each designed for a specific application. Some common types include:

- Single Type: A standard sprocket with one set of teeth.

- Double Type: A sprocket with two sets of teeth, designed to engage with two chains.

- Triple Type: A sprocket with three sets of teeth, designed to engage with three chains.

- Taper Bushed Type: A sprocket with a tapered bushing that is used to mount the sprocket onto a shaft.

- QD Type: A sprocket with a quick-disconnect bushing that allows for easy installation and removal.

Advantages of Roller Chain Sprockets

Roller chain sprockets offer several advantages over other types of power transmission systems, including:

- High Efficiency: Roller chain sprockets have a high mechanical efficiency, which means that less power is lost in the transmission process.

- Reliability: Roller chain sprockets are known for their reliability and durability, even in harsh operating conditions.

- Low Maintenance: Roller chain sprockets require minimal maintenance, reducing maintenance costs over time.

- Easy to Replace: Roller chain sprockets are easy to replace, with many types of sprockets featuring a simple design that allows for quick and easy replacement.

- Wide Range of Sizes: Roller chain sprockets are available in a wide range of sizes and configurations to meet the needs of various applications.

Materials Used in Roller Chain Sprockets

Roller chain sprockets are typically made from steel, which offers a high level of strength and durability. Other materials, such as aluminum and plastic, may also be used for certain applications where weight or corrosion resistance is a concern.

Installation, Maintenance, and Repair of Roller Chain Sprockets

Proper installation, maintenance, and repair are essential for the long-term performance and reliability of roller chain sprockets.

Installation

- Ensure that the sprocket is the correct size and type for the chain and application.

- Clean the shaft and sprocket surface to ensure proper installation.

- Position the sprocket on the shaft in the desired location.

- Secure the sprocket in place using the appropriate fasteners.

- Check for proper alignment and tension before use.

Maintenance

Regular maintenance is essential for the long-term performance and reliability of roller chain sprockets. Some common maintenance tasks include:

- Lubrication: Proper lubrication is essential for the smooth operation of roller chain sprockets. Use a high-quality lubricant and follow the manufacturer's recommendations for application and frequency.

- Inspection: Regular inspection of roller chain sprockets can help identify potential issues before they become major problems. Look for signs of wear, damage, or misalignment, and replace any worn or damaged components as necessary.

Repair

If a roller chain sprocket becomes damaged or worn, it may need to be repaired or replaced. In many cases, it is more cost-effective to replace the sprocket rather than attempt to repair it.

Replacing a Roller Chain Sprocket

Replacing a roller chain sprocket is a relatively simple process that can be completed with basic tools and equipment. The following steps can be used as a general guide:

- Remove any fasteners that are securing the existing sprocket.

- Slide the old sprocket off the shaft and remove it from the chain.

- Slide the new sprocket onto the shaft and position it in the desired location.

- Secure the new sprocket in place using the appropriate fasteners.

- Check for proper alignment and tension before use.

FAQ

- What is a roller chain sprocket?

- What materials are used to make roller chain sprockets?

- What types of roller chain sprockets are available?

- How do I know when it is time to replace a roller chain sprocket?

- Can roller chain sprockets be customized?

A roller chain sprocket is a component in a power transmission system that is used to transmit power from one rotating shaft to another by means of a chain.

Roller chain sprockets are typically made from steel, but other materials such as aluminum and plastic may also be used for certain applications.

There are several types of roller chain sprockets available, including single, double, and triple types, as well as taper bushed and QD types.

Roller chain sprockets should be inspected regularly for signs of wear or damage. Replace the sprocket if any abnormalities are found.

Yes, roller chain sprockets can be customized to meet specific application requirements. Consult the manufacturer for more information.

Author: lmc

Disclaimer: All content on this page is for reference only and is not intended to be a substitute for professional advice. Our products are accessories rather than original spare parts; we are not the holder of the original trademark of the content. Our products are only suitable for aftermarket accessories rather than original spare parts. Our accessories can perfectly fit the original spare parts; if you need to purchase original spare parts, please contact the original factory to purchase.

About us

We guarantee top-quality products at the best prices in China! Special orders are welcome, and if you’re interested in any of our products, feel free to reach out for more detailed information. We ensure our products are safe, high-quality, and reasonably priced. Please contact us as soon as possible if you’d like to learn more. We’re eager to cooperate with you!

A large portion of our products is exported to Europe and the Americas, with both standard and custom options available. We can manufacture according to your drawings or samples, using standard materials or as per your specific requirements. Choosing us means choosing reliability.

Materials Available

1. Stainless Steel: SS201, SS303, SS304, SS316, SS416, SS420

2. Steel:C45(K1045), C46(K1046),C20

3. Brass:C36000 ( C26800), C37700 ( HPb59), C38500( HPb58), C27200(CuZn37), C28000(CuZn40)

4. Bronze: C51000, C52100, C54400, etc

5. Iron: 1213, 12L14,1215

6. Aluminum: Al6061, Al6063

7.OEM according to your request

Surface Treatment

Annealing, natural canonization, heat treatment, polishing, nickel plating, chrome plating, zinc plating,yellow passivization, gold passivization, satin, Black surface painted etc.

Processing Method

CNC machining, punch,turning, milling, drilling, grinding, broaching, welding and assembly

QC & Certificate

Technicians self-check in production,final-check before package by professional Quality inspector

ISO9001:2008 , ISO14001:2001,ISO/TS 16949:2009

Package & Lead Time

Size: Drawings

Wooden Case/Container and pallet, or as per customized specifications.

15-25days samples. 30-45days offcial order

Port: Shanghai/Ningbo port

Industries We Service