rotary tillers pto shafts flange weld yoke triangular steel pipe pto shaft

Rotary Tillers PTO Shaft: A Comprehensive Guide

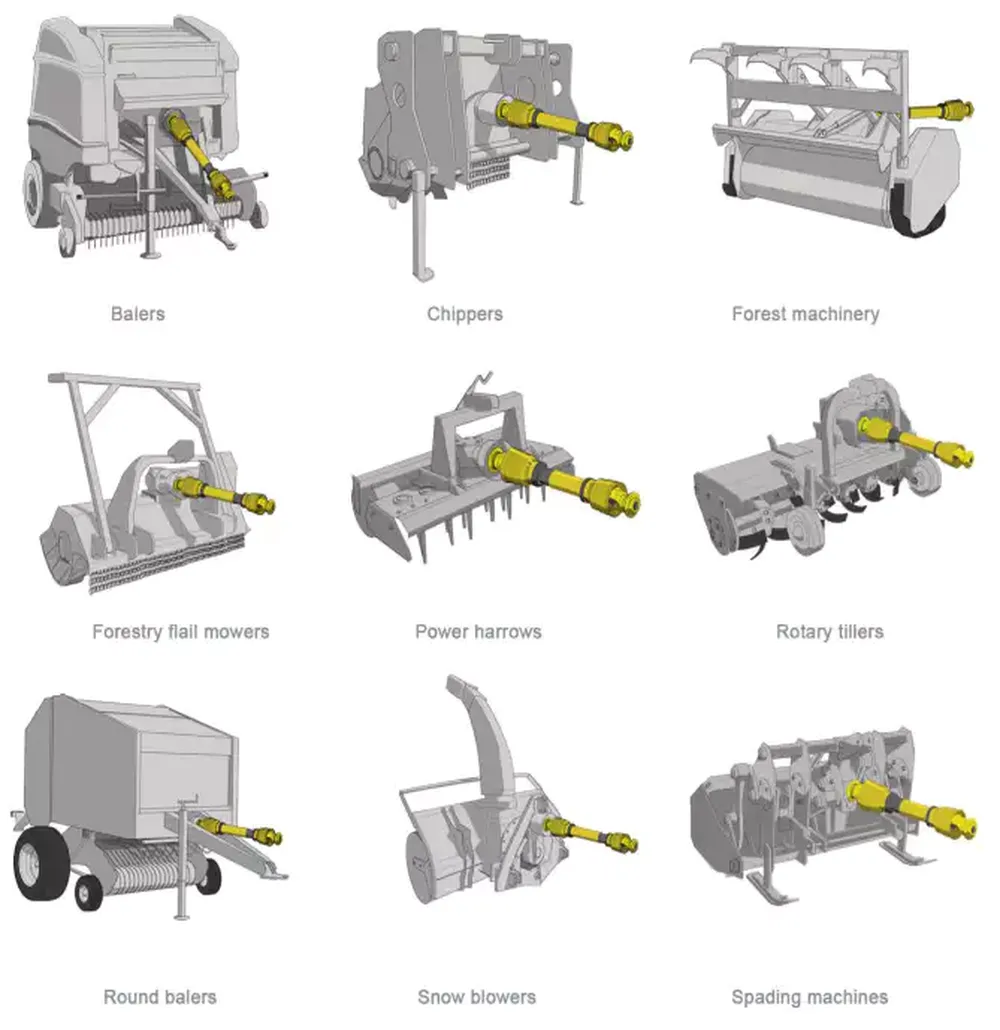

The rotary tiller PTO shafts flange weld yoke triangular steel pipe PTO shaft is a high-quality product designed for use in various industries such as hotels, garment shops, building material shops, manufacturing plants, machinery repair shops, food & beverage factories, farms, restaurants, home use, retail, food shops, printing shops, construction works, energy & mining, food & beverage shops, and other related fields. This versatile product is ideal for use with tractors and farm implements, making it an essential tool for many agricultural applications.

Product History

The rotary tillers PTO shaft has been in use for many years and has undergone significant improvements over time to make it more efficient and durable. The current design features a flange weld yoke triangular steel pipe PTO shaft, which is forged and cold-drawn to ensure maximum performance and reliability.

Product Classification

The rotary tillers PTO shaft can be classified according to its teeth, processing of yoke, processing of tube, cross kit, tubes, yoke, and color. The product also comes with a full range of cross kit and customized tubes to meet different customer requirements.

Product Advantages

- High-quality material

- Excellent performance

- Durable and reliable

- Easy to install, maintain, and repair

- Full range of cross kit and customized tubes

Available Product Materials

The rotary tillers PTO shaft is made of high-quality materials such as steel, which ensures maximum durability and reliability. The product is also available in various colors to suit different customer preferences.

How to Install, Maintain, and Repair the Product?

The rotary tillers PTO shaft is easy to install, maintain, and repair. It is advisable to follow the manufacturer's instructions when installing the product to ensure maximum performance and reliability. The product should be regularly maintained to keep it in good working condition. When repairing the product, it is important to use genuine spare parts to ensure that the product retains its original performance and reliability.

How to Replace the Product?

When replacing the rotary tillers PTO shaft, it is important to ensure that the new product is compatible with the existing system. It is also advisable to consult the manufacturer for guidance on how to replace the product to ensure that it is done correctly.

Other Products from Our Company

At our company, we specialize in supplying various industrial plastic gears such as agricultural gearboxes, power output shafts, sprockets, hydraulic couplings, worm gear reducers, gear racks, removable chains, pulleys and pulleys, planetary gearboxes, timing pulleys, bushings, and other related products. Our products are of high quality, available at a preferential price, and come with thoughtful customer service. We welcome customers to customize with pictures and samples.

Questions and Answers

Q1. What is a rotary tillers PTO shaft?

A1. A rotary tillers PTO shaft is a high-quality product designed for use with tractors and farm implements. It is ideal for various agricultural applications.

Q2. What are the advantages of a rotary tillers PTO shaft?

A2. The rotary tillers PTO shaft is made of high-quality material, has excellent performance, is durable and reliable, and comes with a full range of cross kits and customized tubes to meet different customer requirements.

Q3. How do I install a rotary tillers PTO shaft?

A3. When installing a rotary tillers PTO shaft, it is advisable to follow the manufacturer's instructions to ensure maximum performance and reliability.

Q4. What should I do when repairing a rotary tillers PTO shaft?

A4. When repairing a rotary tillers PTO shaft, it is important to use genuine spare parts to ensure that the product retains its original performance and reliability.

Q5. What other products does your company supply?

A5. At our company, we specialize in supplying various industrial plastic gears such as agricultural gearboxes, power output shafts, sprockets, hydraulic couplings, worm gear reducers, gear racks, removable chains, pulleys and pulleys, planetary gearboxes, timing pulleys, bushings, and other related products.

Disclaimer: All content on this page is for reference only and is not a substitute for professional advice or a recommendation. Our products are accessories rather than original spare parts; we are not the holder of the original trademark of the content. Our products are only suitable for aftermarket accessories rather than original spare parts. Our accessories can perfectly fit the original spare parts; if you need to purchase original spare parts, please contact the original factory to purchase.

Author: lmc

About us

We guarantee top-quality products at the best prices in China! Special orders are welcome, and if you’re interested in any of our products, feel free to reach out for more detailed information. We ensure our products are safe, high-quality, and reasonably priced. Please contact us as soon as possible if you’d like to learn more. We’re eager to cooperate with you!

A large portion of our products is exported to Europe and the Americas, with both standard and custom options available. We can manufacture according to your drawings or samples, using standard materials or as per your specific requirements. Choosing us means choosing reliability.

Materials Available

1. Stainless Steel: SS201, SS303, SS304, SS316, SS416, SS420

2. Steel:C45(K1045), C46(K1046),C20

3. Brass:C36000 ( C26800), C37700 ( HPb59), C38500( HPb58), C27200(CuZn37), C28000(CuZn40)

4. Bronze: C51000, C52100, C54400, etc

5. Iron: 1213, 12L14,1215

6. Aluminum: Al6061, Al6063

7.OEM according to your request

Surface Treatment

Annealing, natural canonization, heat treatment, polishing, nickel plating, chrome plating, zinc plating,yellow passivization, gold passivization, satin, Black surface painted etc.

Processing Method

CNC machining, punch,turning, milling, drilling, grinding, broaching, welding and assembly

QC & Certificate

Technicians self-check in production,final-check before package by professional Quality inspector

ISO9001:2008 , ISO14001:2001,ISO/TS 16949:2009

Package & Lead Time

Size: Drawings

Wooden Case/Container and pallet, or as per customized specifications.

15-25days samples. 30-45days offcial order

Port: Shanghai/Ningbo port

Industries We Service