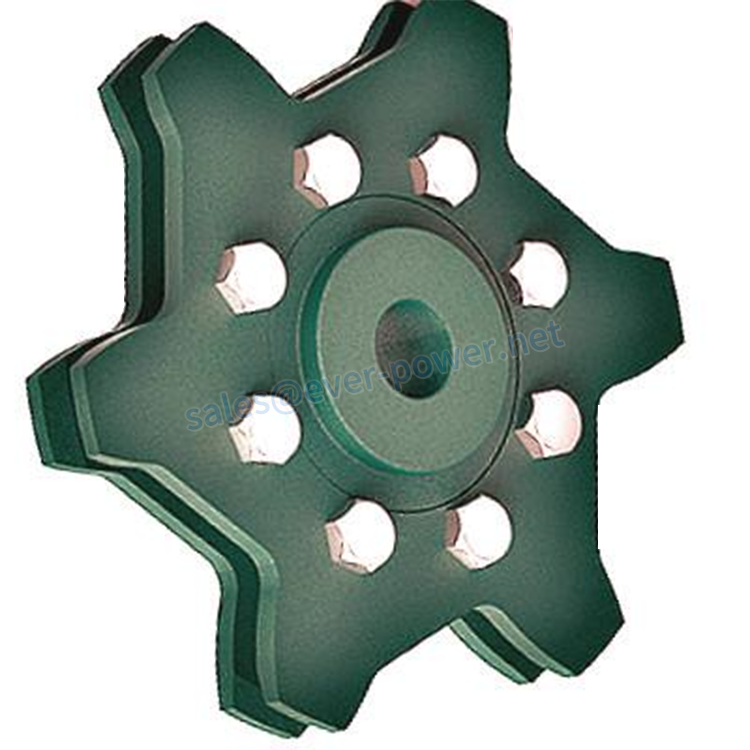

Scraper Chain Sprocket

Applications and Advantages of Scraper Chain Sprockets

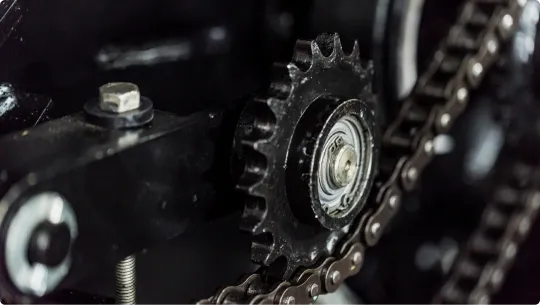

Scraper Chain Sprockets are an essential component used in various industrial applications. They are used in conveyor systems, elevators, and other heavy-duty equipment to transfer power or motion between two parallel shafts. These sprockets are mainly used in applications where heavy loads need to be transferred smoothly and precisely.

These sprockets are constructed using high-quality raw material under the astute supervision of our dexterous team in compliance with the industry laid parameters. They are manufactured using high-grade raw material to ensure their error-free nature. These sprockets are ruggedly constructed with a smooth finish, which ensures a longer service life with minimal maintenance.

History and Classification of Scraper Chain Sprockets

The history of sprockets can be traced back to the early 1900s when the industrial revolution was in full swing. Sprockets were invented as a need for more precise and smooth power transmission arose. Since then, they have undergone numerous changes and advancements to meet the growing demands of various industries.

Scraper Chain Sprockets are classified into various types based on their design, pitch, and material used. The commonly used types are simplex, duplex, and triplex sprockets. They are also classified based on the number of teeth, bore size, and pitch diameter.

Advantages of Scraper Chain Sprockets

Scraper Chain Sprockets have numerous advantages, such as:

- High load-bearing capacity

- Precision and smooth power transmission

- Long service life with low maintenance

- Resistance to corrosion and wear

- No slipping during operation

Available Materials and Installation

Scraper Chain Sprockets are manufactured using different types of materials such as steel, cast iron, and plastic. The material used depends on the application and the load-bearing capacity required.

The installation of these sprockets is relatively simple and can be done with basic tools. It is essential to keep the sprockets clean and free from debris as any buildup can cause them to malfunction.

Maintenance and Repair

Proper maintenance of Scraper Chain Sprockets is crucial to ensure their longevity and smooth operation. Regular cleaning and lubrication should be carried out to prevent any wear and tear or corrosion. In case of damage or malfunction, it is recommended to replace the sprocket immediately to avoid any further damage to the equipment.

Other Products Offered by Our Company

At our company, we offer a wide range of industrial plastic gears such as agricultural gearboxes, power output shafts, hydraulic couplings, worm gear reducers, gear racks, removable chains, pulleys, and pulleys, planetary gearboxes, timing pulleys, and bushings. Our products are of high quality, and we offer them at competitive prices to meet the needs of our customers. We welcome our customers to customize products with pictures and samples.

Frequently Asked Questions (FAQs)

Q1. What are Scraper Chain Sprockets?

Scraper Chain Sprockets are an essential component used in various industrial applications. They are mainly used in conveyor systems, elevators, and other heavy-duty equipment to transfer power or motion between two parallel shafts.

Q2. What are the advantages of using Scraper Chain Sprockets?

Scraper Chain Sprockets have numerous advantages, such as high load-bearing capacity, precision and smooth power transmission, long service life with low maintenance, resistance to corrosion and wear, and no slipping during operation.

Q3. What materials are used to manufacture Scraper Chain Sprockets?

Scraper Chain Sprockets are manufactured using different types of materials such as steel, cast iron, and plastic. The material used depends on the application and the load-bearing capacity required.

Q4. How should Scraper Chain Sprockets be maintained?

Proper maintenance of Scraper Chain Sprockets is crucial to ensure their longevity and smooth operation. Regular cleaning and lubrication should be carried out to prevent any wear and tear or corrosion.

Q5. What other products are offered by your company?

At our company, we offer a wide range of industrial plastic gears such as agricultural gearboxes, power output shafts, hydraulic couplings, worm gear reducers, gear racks, removable chains, pulleys, and pulleys, planetary gearboxes, timing pulleys, and bushings.

About us

We guarantee top-quality products at the best prices in China! Special orders are welcome, and if you’re interested in any of our products, feel free to reach out for more detailed information. We ensure our products are safe, high-quality, and reasonably priced. Please contact us as soon as possible if you’d like to learn more. We’re eager to cooperate with you!

A large portion of our products is exported to Europe and the Americas, with both standard and custom options available. We can manufacture according to your drawings or samples, using standard materials or as per your specific requirements. Choosing us means choosing reliability.

Materials Available

1. Stainless Steel: SS201, SS303, SS304, SS316, SS416, SS420

2. Steel:C45(K1045), C46(K1046),C20

3. Brass:C36000 ( C26800), C37700 ( HPb59), C38500( HPb58), C27200(CuZn37), C28000(CuZn40)

4. Bronze: C51000, C52100, C54400, etc

5. Iron: 1213, 12L14,1215

6. Aluminum: Al6061, Al6063

7.OEM according to your request

Surface Treatment

Annealing, natural canonization, heat treatment, polishing, nickel plating, chrome plating, zinc plating,yellow passivization, gold passivization, satin, Black surface painted etc.

Processing Method

CNC machining, punch,turning, milling, drilling, grinding, broaching, welding and assembly

QC & Certificate

Technicians self-check in production,final-check before package by professional Quality inspector

ISO9001:2008 , ISO14001:2001,ISO/TS 16949:2009

Package & Lead Time

Size: Drawings

Wooden Case/Container and pallet, or as per customized specifications.

15-25days samples. 30-45days offcial order

Port: Shanghai/Ningbo port

Industries We Service