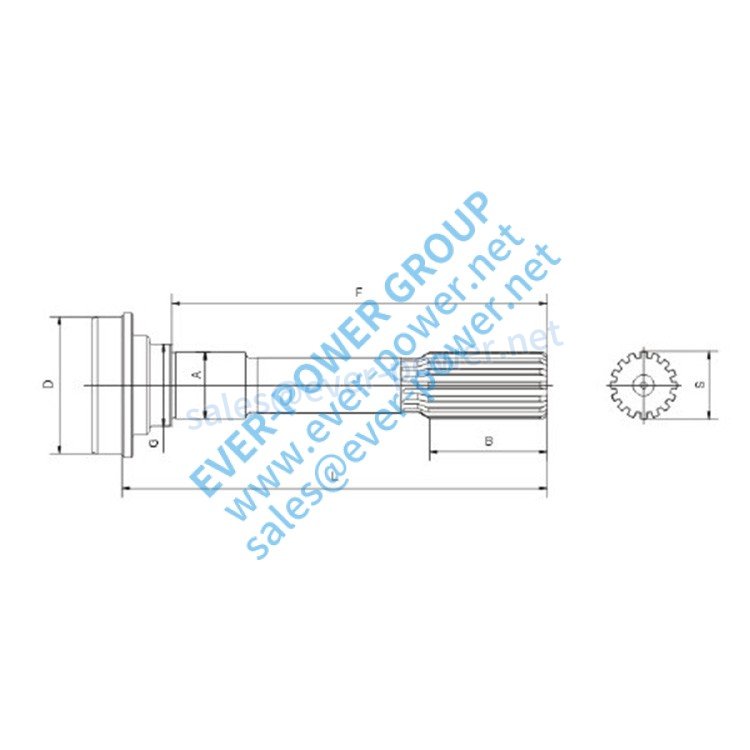

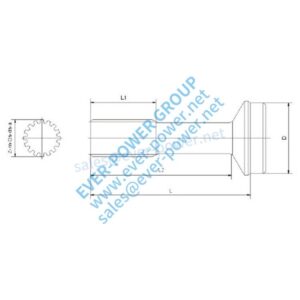

Spline shaft

Spline Shaft: A Comprehensive Guide

A spline shaft is an essential mechanical component used in various industries for transmitting torque. It is a cylindrical mechanical component with grooves on its surface that allow it to connect with other mechanical devices such as gears, pulleys, and couplings. The splines on the shaft engage with the matching grooves of the mating component to provide a secure and efficient power transmission.

History

The concept of spline shaft dates back to the early 1900s when engineers realized the need for a flexible power transmission solution that could withstand high torque and axial loads. The original use of spline shafts was in the automotive industry, but now they are extensively used in various industries, including aerospace, heavy equipment, and marine.

Classification and Material

Spline shafts come in various sizes and shapes and are classified based on their number of teeth, pressure angle, and pitch. The most commonly used pressure angles are 20 degrees and 30 degrees, and the most common pitches are 6 and 10. The material used for spline shafts varies depending on the application. Some of the commonly used materials include steel, aluminum, and brass.

Advantages

- High torque capacity

- Efficient power transmission

- Easy installation and maintenance

- Accurate positioning

- Absorption of shock loads and vibrations

Installation, Maintenance, and Repair

The installation of spline shafts depends on the mating component and the application. It is crucial to ensure that the shaft is correctly aligned and that the splines are clean before installation. Proper maintenance of the shaft is essential to prevent wear and tear. Regular cleaning and lubrication of the shaft can significantly extend its life. In case of damage or wear and tear, the shaft can be repaired or replaced, depending on the extent of damage.

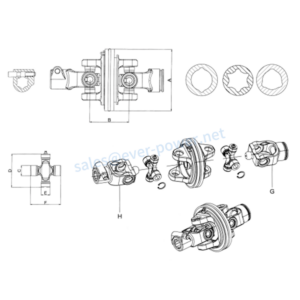

Other Products

Our company mainly supplies various plastic gears used in the industry, such as agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, detachable chains, pulleys and pulleys, planetary gearboxes, timing pulleys, bushings, and more. Our products are of high quality, with favorable prices and considerate services. We welcome customers to come to us for drawing or sample customization.

Q&A

1. What is the purpose of a spline shaft?

A spline shaft is used for transmitting torque from one mechanical component to another.

2. What are the common materials used for spline shafts?

Some of the commonly used materials for spline shafts include steel, aluminum, and brass.

3. Can spline shafts be repaired?

Yes, spline shafts can be repaired or replaced, depending on the extent of the damage.

4. What is the history of spline shafts?

The concept of spline shafts dates back to the early 1900s when engineers realized the need for a flexible power transmission solution that could withstand high torque and axial loads.

5. What are the advantages of using spline shafts?

- High torque capacity

- Efficient power transmission

- Easy installation and maintenance

- Accurate positioning

- Absorption of shock loads and vibrations

About us

We guarantee top-quality products at the best prices in China! Special orders are welcome, and if you’re interested in any of our products, feel free to reach out for more detailed information. We ensure our products are safe, high-quality, and reasonably priced. Please contact us as soon as possible if you’d like to learn more. We’re eager to cooperate with you!

A large portion of our products is exported to Europe and the Americas, with both standard and custom options available. We can manufacture according to your drawings or samples, using standard materials or as per your specific requirements. Choosing us means choosing reliability.

Materials Available

1. Stainless Steel: SS201, SS303, SS304, SS316, SS416, SS420

2. Steel:C45(K1045), C46(K1046),C20

3. Brass:C36000 ( C26800), C37700 ( HPb59), C38500( HPb58), C27200(CuZn37), C28000(CuZn40)

4. Bronze: C51000, C52100, C54400, etc

5. Iron: 1213, 12L14,1215

6. Aluminum: Al6061, Al6063

7.OEM according to your request

Surface Treatment

Annealing, natural canonization, heat treatment, polishing, nickel plating, chrome plating, zinc plating,yellow passivization, gold passivization, satin, Black surface painted etc.

Processing Method

CNC machining, punch,turning, milling, drilling, grinding, broaching, welding and assembly

QC & Certificate

Technicians self-check in production,final-check before package by professional Quality inspector

ISO9001:2008 , ISO14001:2001,ISO/TS 16949:2009

Package & Lead Time

Size: Drawings

Wooden Case/Container and pallet, or as per customized specifications.

15-25days samples. 30-45days offcial order

Port: Shanghai/Ningbo port

Industries We Service