Sprockets For Conveyor Roller Chains

Sprockets for Conveyor Roller Chains

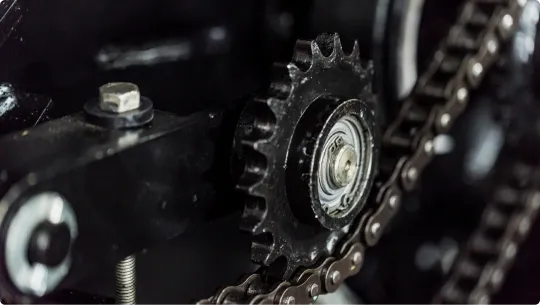

Roller chains are commonly used in conveyor systems to facilitate the movement of heavy loads. Sprockets are an essential component of these chains, as they transmit power from the motor to the chain, which then moves the load. These sprockets are made using slotting machines and are flanged to ensure smooth and precise movement of the chain.

Our company is a leading supplier of sprockets for conveyor roller chains, including those used by major roller producers such as Interroll. While we do not produce the rollers themselves, we offer high-quality sprockets that are designed to fit perfectly with Interroll's roller chains.

Roller chain sprockets are used in a wide range of applications, including in manufacturing plants, assembly lines, and packing facilities. They are especially useful when transporting heavy items, such as pallets, boxes, and containers.

Advantages of Roller Chain Sprockets

- Highly durable, as they are made from high-quality materials such as steel, stainless steel, and plastic.

- Can be customized to fit specific chains and loads, ensuring optimal performance and efficiency.

- Easy to install and maintain, with minimal downtime required for repairs and replacements.

- Available in a variety of sizes and designs to meet specific application requirements.

Types of Roller Chain Sprockets

Roller chain sprockets can be classified according to their shape, size, tooth profile, and materials used. Some of the common types of roller chain sprockets include:

- Standard sprockets

- Tapered bore sprockets

- Double duty sprockets

- Hardened sprockets

- Idler sprockets

How to Install and Maintain Roller Chain Sprockets

Installing and maintaining roller chain sprockets is relatively easy and straightforward. Here are some tips to keep in mind:

- Ensure that the sprocket is properly aligned with the chain, with no lateral movement.

- Maintain proper tension on the chain to prevent slippage and premature wear.

- Periodically check for signs of wear and damage, such as worn-out teeth or cracks.

- Keep the sprocket clean and free of debris, which can interfere with its movement.

- Replace worn or damaged sprockets promptly to avoid further damage to the chain and other components.

Other Products Offered by Our Company

In addition to roller chain sprockets, our company also supplies a wide range of industrial plastic gears, including agricultural gearboxes, power output shafts, hydraulic couplings, worm gear reducers, gear racks, removable chains, pulleys and pulleys, planetary gearboxes, timing pulleys, and bushings. We are committed to providing high-quality products at competitive prices, backed by exceptional customer service and support.

Questions and Answers

Q: What are roller chain sprockets?

A: Roller chain sprockets are components used in conveyor systems to transmit power from the motor to the chain, which then moves the load.

Q: What are the advantages of roller chain sprockets?

A: Roller chain sprockets are highly durable, customizable, and easy to install and maintain. They are available in a variety of sizes and designs to meet specific application requirements.

Q: What are the common types of roller chain sprockets?

A: Common types of roller chain sprockets include standard sprockets, tapered bore sprockets, double duty sprockets, hardened sprockets, and idler sprockets.

Q: How do you install and maintain roller chain sprockets?

A: Proper alignment with the chain, maintaining proper tension, periodic checks for wear and damage, and keeping the sprocket clean are important considerations for installing and maintaining roller chain sprockets.

Q: What other products does your company offer?

A: Our company offers a wide range of industrial plastic gears, including agricultural gearboxes, power output shafts, hydraulic couplings, worm gear reducers, gear racks, removable chains, pulleys and pulleys, planetary gearboxes, timing pulleys, and bushings.

Q: How does your company ensure product quality and customer satisfaction?

A: We are committed to providing high-quality products at competitive prices, backed by exceptional customer service and support. We work closely with our customers to understand their needs and requirements, and we strive to exceed their expectations at every step of the process.

All content on this page is from the Internet and is only used as a reference for product selection. Our products are accessories rather than original spare parts, and we are not the holder of the original trademark of the content. Our accessories can perfectly fit the original spare parts; if you need to purchase original spare parts, please contact the original factory to purchase.

Author: lmc

About us

We guarantee top-quality products at the best prices in China! Special orders are welcome, and if you’re interested in any of our products, feel free to reach out for more detailed information. We ensure our products are safe, high-quality, and reasonably priced. Please contact us as soon as possible if you’d like to learn more. We’re eager to cooperate with you!

A large portion of our products is exported to Europe and the Americas, with both standard and custom options available. We can manufacture according to your drawings or samples, using standard materials or as per your specific requirements. Choosing us means choosing reliability.

Materials Available

1. Stainless Steel: SS201, SS303, SS304, SS316, SS416, SS420

2. Steel:C45(K1045), C46(K1046),C20

3. Brass:C36000 ( C26800), C37700 ( HPb59), C38500( HPb58), C27200(CuZn37), C28000(CuZn40)

4. Bronze: C51000, C52100, C54400, etc

5. Iron: 1213, 12L14,1215

6. Aluminum: Al6061, Al6063

7.OEM according to your request

Surface Treatment

Annealing, natural canonization, heat treatment, polishing, nickel plating, chrome plating, zinc plating,yellow passivization, gold passivization, satin, Black surface painted etc.

Processing Method

CNC machining, punch,turning, milling, drilling, grinding, broaching, welding and assembly

QC & Certificate

Technicians self-check in production,final-check before package by professional Quality inspector

ISO9001:2008 , ISO14001:2001,ISO/TS 16949:2009

Package & Lead Time

Size: Drawings

Wooden Case/Container and pallet, or as per customized specifications.

15-25days samples. 30-45days offcial order

Port: Shanghai/Ningbo port

Industries We Service