Stainless Steel Sprockets

Stainless Steel Sprockets for High-Performance Industrial Machinery

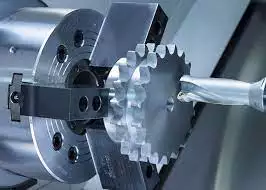

Stainless steel sprockets are an essential component of high-performance industrial machinery. They are designed to transfer power from one rotating shaft to another through a chain drive system. These sprockets come in various types, including single-strand, double-strand, triple-strand, and quadruple-strand, and are available in different materials such as stainless steel, cast iron, and plastic.

Product History and Classification

Stainless steel sprockets have been used in industrial machinery for decades. They are known for their durability, strength, and resistance to corrosion. The American National Standards Institute (ANSI) has set standards for sprockets, including dimensions, tolerances, materials, and more.

Advantages of Stainless Steel Sprockets

Stainless steel sprockets offer several advantages over sprockets made from other materials. They are highly resistant to corrosion, making them ideal for use in harsh environments. They are also easy to clean and maintain, which helps prolong their lifespan. In addition, stainless steel sprockets have excellent fatigue resistance, making them ideal for high-speed and high-load applications.

Available Materials

Stainless steel sprockets are typically made from 304- or 316-grade stainless steel, but other grades are available upon request. These sprockets can be supplied as A-Plate style or B-Hub style, with standard or finished bores.

Installation, Maintenance, and Repair

Installing and maintaining stainless steel sprockets is relatively easy. Before installation, ensure that the sprocket is properly lubricated and that the chain is correctly tensioned. Check the sprocket regularly for signs of wear, and replace it if necessary. To repair a worn sprocket, it can be re-machined or replaced with a new one.

Usage Scenarios

Stainless steel sprockets are commonly used in various industrial machinery, including conveyor systems, packaging equipment, printing presses, and more. They are also used in the food and beverage industry, where hygiene and cleanliness are critical.

Other Industrial Plastic Gears and Accessories

Aside from stainless steel sprockets, we also offer a wide range of industrial plastic gears and accessories. Our products include agricultural gearboxes, power output shafts, hydraulic couplings, worm gear reducers, gear racks, removable chains, pulleys, planetary gearboxes, timing pulleys, bushings, and more. We take pride in offering high-quality products at competitive prices, coupled with excellent customer service. We welcome customization requests, and we are committed to meeting the unique needs of our customers.

Questions and Answers

Q: What are stainless steel sprockets?

A: Stainless steel sprockets are an essential component of chain drive systems used in industrial machinery. They transfer power from one rotating shaft to another.

Q: What materials are available for stainless steel sprockets?

A: Stainless steel sprockets are typically made from 304- or 316-grade stainless steel. Other grades are available upon request.

Q: What are the advantages of stainless steel sprockets?

A: Stainless steel sprockets are highly resistant to corrosion, easy to clean and maintain, and have excellent fatigue resistance. They are ideal for high-speed and high-load applications.

Q: What are the common usage scenarios of stainless steel sprockets?

A: Stainless steel sprockets are commonly used in conveyor systems, printing presses, packaging equipment, and the food and beverage industry.

Q: How do you install and maintain stainless steel sprockets?

A: Before installation, ensure that the sprocket is properly lubricated and that the chain is correctly tensioned. Check the sprocket regularly for signs of wear, and replace it if necessary. To repair a worn sprocket, it can be re-machined or replaced with a new one.

Q: What other products does your company offer?

A: We offer a wide range of industrial plastic gears and accessories, including agricultural gearboxes, power output shafts, hydraulic couplings, worm gear reducers, gear racks, and more. We take pride in offering high-quality products at competitive prices, coupled with excellent customer service.

About us

We guarantee top-quality products at the best prices in China! Special orders are welcome, and if you’re interested in any of our products, feel free to reach out for more detailed information. We ensure our products are safe, high-quality, and reasonably priced. Please contact us as soon as possible if you’d like to learn more. We’re eager to cooperate with you!

A large portion of our products is exported to Europe and the Americas, with both standard and custom options available. We can manufacture according to your drawings or samples, using standard materials or as per your specific requirements. Choosing us means choosing reliability.

Materials Available

1. Stainless Steel: SS201, SS303, SS304, SS316, SS416, SS420

2. Steel:C45(K1045), C46(K1046),C20

3. Brass:C36000 ( C26800), C37700 ( HPb59), C38500( HPb58), C27200(CuZn37), C28000(CuZn40)

4. Bronze: C51000, C52100, C54400, etc

5. Iron: 1213, 12L14,1215

6. Aluminum: Al6061, Al6063

7.OEM according to your request

Surface Treatment

Annealing, natural canonization, heat treatment, polishing, nickel plating, chrome plating, zinc plating,yellow passivization, gold passivization, satin, Black surface painted etc.

Processing Method

CNC machining, punch,turning, milling, drilling, grinding, broaching, welding and assembly

QC & Certificate

Technicians self-check in production,final-check before package by professional Quality inspector

ISO9001:2008 , ISO14001:2001,ISO/TS 16949:2009

Package & Lead Time

Size: Drawings

Wooden Case/Container and pallet, or as per customized specifications.

15-25days samples. 30-45days offcial order

Port: Shanghai/Ningbo port

Industries We Service