The fixed transmission shaft assembly (NFB NFC)

The Fixed Transmission Shaft Assembly (NFB NFC)

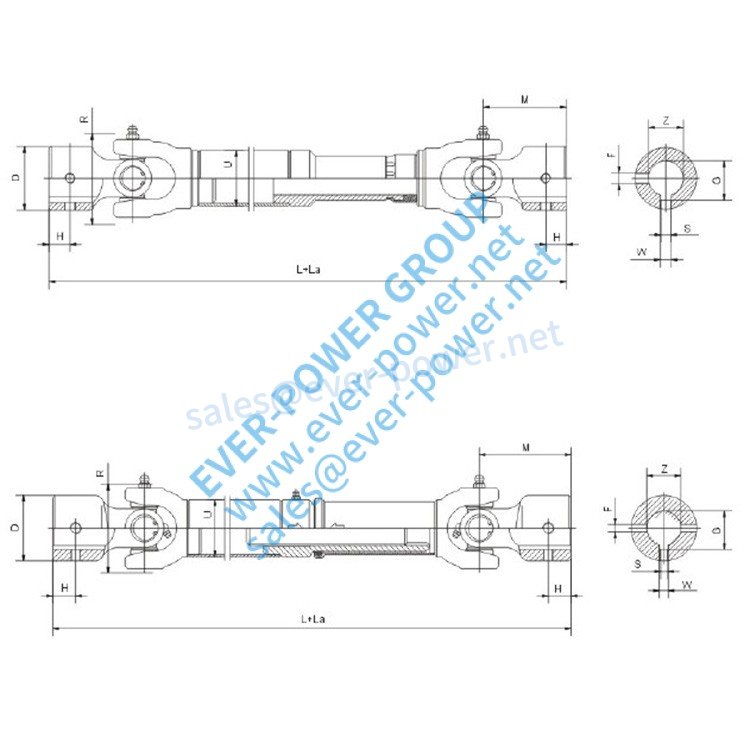

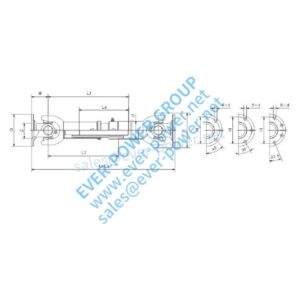

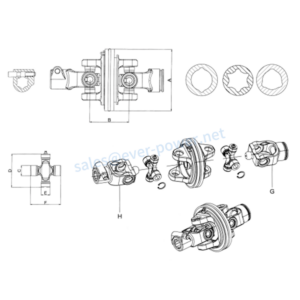

The fixed transmission shaft assembly (NFB NFC) is a crucial component in various industrial applications. It is designed to transmit power and rotational motion between different parts of a machine or equipment. This assembly consists of a fixed transmission shaft, bearings, and other supporting components, ensuring smooth and efficient power transmission.

Common Use Scenarios

- Automotive Industry: The fixed transmission shaft assembly is widely used in vehicles, connecting the engine to the wheels and enabling the transfer of power.

- Industrial Machinery: It plays a vital role in industrial equipment such as conveyors, pumps, and machine tools, ensuring the synchronized rotation of different parts.

- Construction Equipment: This assembly is utilized in construction machinery like cranes and excavators, enabling the efficient transfer of power for various operations.

Product History and Classification

The fixed transmission shaft assembly has a rich history dating back to the early days of mechanical engineering. Over time, advancements in materials, manufacturing techniques, and design have led to improved performance and reliability. There are different types of fixed transmission shaft assemblies available, each designed to meet specific application requirements.

Advantages

- Efficient Power Transmission: The fixed transmission shaft assembly ensures smooth power transfer, minimizing energy loss and maximizing overall efficiency.

- Durable and Reliable: Constructed from high-quality materials, this assembly offers excellent strength and durability, withstanding heavy loads and harsh operating conditions.

- Easy Installation and Maintenance: The assembly is designed for straightforward installation and requires minimal maintenance, reducing downtime and operational costs.

- Versatile Compatibility: It can be used with various types of machinery and equipment, making it a versatile solution for different industries.

Materials and Installation

The fixed transmission shaft assembly can be manufactured from materials such as steel, alloy, or carbon fiber, depending on the specific application requirements. The choice of material ensures optimal strength, durability, and resistance to wear and tear.

When installing the assembly, it is crucial to follow the manufacturer's guidelines. Proper alignment, lubrication, and torque settings are essential to ensure optimal performance and longevity of the assembly.

Maintenance, Repair, and Replacement

To maintain the performance of the fixed transmission shaft assembly, regular inspections and maintenance should be performed. This includes checking for signs of wear or damage, lubricating the bearings, and addressing any issues promptly.

In the event of a malfunction or failure, the assembly may require repair or replacement. It is recommended to consult a qualified technician or contact the original supplier for assistance in diagnosing and resolving any issues.

Other Products and Business

In addition to the fixed transmission shaft assembly, our company offers a wide range of high-quality industrial components. We specialize in supplying various Plastic Gear used in industry, catering to diverse applications. Our product range includes agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, detachable chains, pulleys and pulleys, planetary gearboxes, timing pulleys, bushings, and more.

At our company, we pride ourselves on delivering products of the highest quality, along with competitive prices and exceptional service. We welcome customers to inquire about our products, whether they require customization based on drawings or samples. Your satisfaction is our utmost priority.

Q&A

1. What are the common applications of the fixed transmission shaft assembly?

2. How does the choice of materials impact the performance of the assembly?

3. What steps should be followed for the proper installation of the assembly?

4. How can the fixed transmission shaft assembly be maintained to ensure longevity?

5. If a malfunction occurs, how can the assembly be repaired or replaced?

About us

We guarantee top-quality products at the best prices in China! Special orders are welcome, and if you’re interested in any of our products, feel free to reach out for more detailed information. We ensure our products are safe, high-quality, and reasonably priced. Please contact us as soon as possible if you’d like to learn more. We’re eager to cooperate with you!

A large portion of our products is exported to Europe and the Americas, with both standard and custom options available. We can manufacture according to your drawings or samples, using standard materials or as per your specific requirements. Choosing us means choosing reliability.

Materials Available

1. Stainless Steel: SS201, SS303, SS304, SS316, SS416, SS420

2. Steel:C45(K1045), C46(K1046),C20

3. Brass:C36000 ( C26800), C37700 ( HPb59), C38500( HPb58), C27200(CuZn37), C28000(CuZn40)

4. Bronze: C51000, C52100, C54400, etc

5. Iron: 1213, 12L14,1215

6. Aluminum: Al6061, Al6063

7.OEM according to your request

Surface Treatment

Annealing, natural canonization, heat treatment, polishing, nickel plating, chrome plating, zinc plating,yellow passivization, gold passivization, satin, Black surface painted etc.

Processing Method

CNC machining, punch,turning, milling, drilling, grinding, broaching, welding and assembly

QC & Certificate

Technicians self-check in production,final-check before package by professional Quality inspector

ISO9001:2008 , ISO14001:2001,ISO/TS 16949:2009

Package & Lead Time

Size: Drawings

Wooden Case/Container and pallet, or as per customized specifications.

15-25days samples. 30-45days offcial order

Port: Shanghai/Ningbo port

Industries We Service