Weasler PTO Shaft Replacement without Connecting Yokes AB4, B4 1010 P6/P5

PTO Shaft: Definition, Types, and Applications

A Power Take-Off (PTO) Shaft is a mechanical device that connects an agricultural tractor or other vehicle's power source to a variety of attachments or separate machines. PTO shafts are used in a wide range of applications, including agricultural machinery, industrial equipment, transportation equipment, and solar tracking systems. They are available in various types, including standard PTO shafts, telescoping PTO shafts, and constant velocity PTO shafts. PTO shafts can be customized according to specific length, torque, and power requirements.

History of PTO Shaft

The concept of a PTO shaft can be traced back to the 19th century when steam-powered machines required a mechanical connection to provide power to other machines. The first PTO shafts were designed to use a flat belt to transfer power, but it was later replaced by a splined shaft design that provides higher torque transmission and better reliability.

Types of PTO Shaft

There are three main types of PTO shafts: standard PTO shafts, telescoping PTO shafts, and constant velocity PTO shafts. The standard PTO shaft is the most common type and can be used for most applications. A telescoping PTO shaft can be adjusted according to the required length and provides greater flexibility. A constant velocity PTO shaft is designed to maintain a constant speed and can be used for high-speed applications.

Advantages of PTO Shaft

PTO shafts provide several advantages, including:

- Flexibility to match specific needs

- Customizable according to different specifications

- Ability to operate under high-speed conditions and maintain stability

- Designed with a universal joint, which allows for flexible rotation and better power transmission

Applications of PTO Shaft

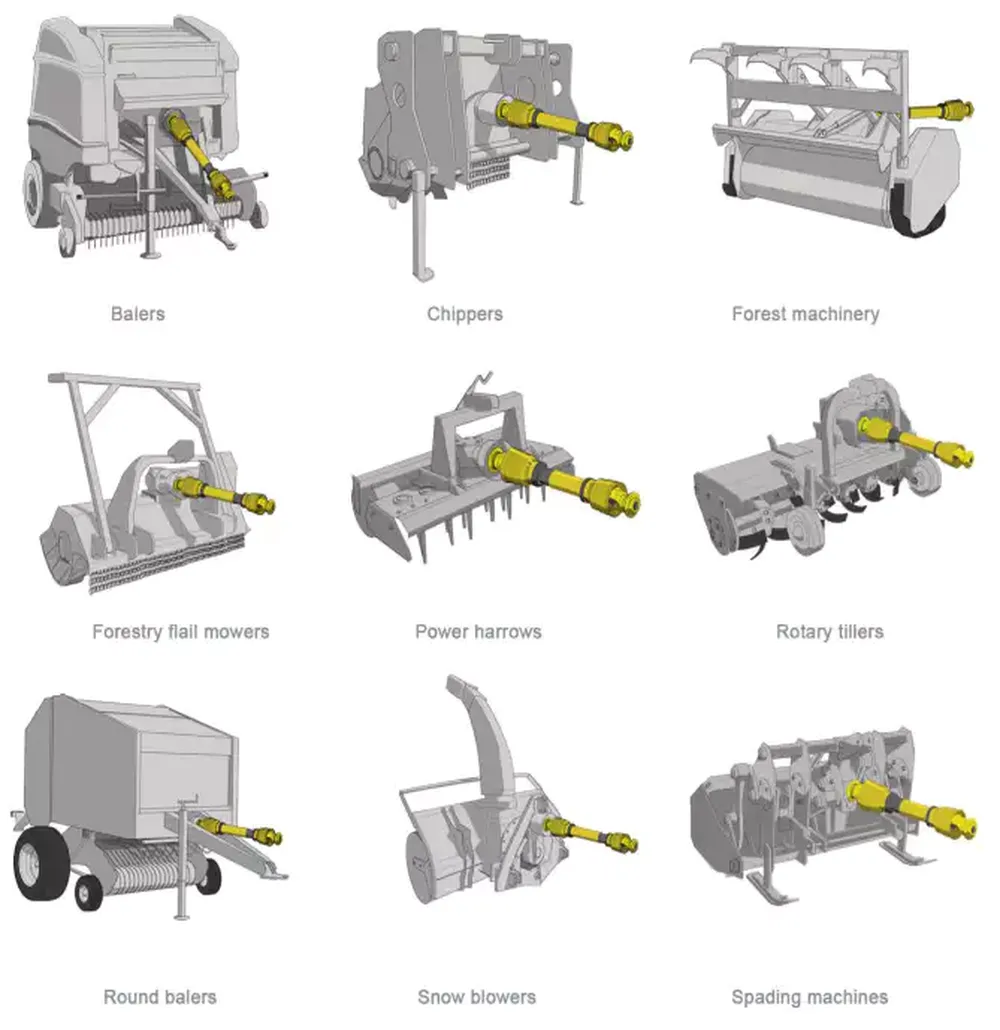

PTO shafts are commonly used in various applications, including:

- Agricultural machinery: Connects tractors to equipment like mowers, harvesters, straw crushers, sprayers, mixers, etc.

- Industrial equipment: Drives rotating equipment such as pumps, generators, centrifuges, mixers, etc.

- Transportation equipment: Drives equipment like trailers, semi-trailers, and tow trucks.

- Solar systems: Used to rotate and adjust photovoltaic panels on trackers.

Product Materials and Installation

PTO shafts are made of high-quality materials, including steel and aluminum alloys, to ensure durability and longevity. To install a PTO shaft, follow the manufacturer's instructions, and ensure that the shaft is compatible with the machine it connects with. When adjusting the length of a PTO shaft, remove the plastic protective cover, shorten the inner and outer tubes according to the required length, remove burrs with a file, oil the inner tube of the steel pipe, and then reinstall the drive shaft plastic protective cover.

Maintenance and Repair of PTO Shaft

To maintain a PTO shaft, regularly check and lubricate the shaft and universal joint. Replace any worn or damaged parts and ensure that the protective cover is in good condition. If the PTO shaft needs repair, consult a certified technician or the manufacturer's instructions.

Replacing a PTO Shaft

If a PTO shaft needs to be replaced, ensure that the replacement shaft has the same dimensions and installation methods as the original. Always choose a PTO shaft that is compatible with the machine it connects with.

About HZPT Group

HZPT Group is a leading supplier of various transmission components, including agricultural gearboxes, power output shafts, sprockets, hydraulic couplings, worm gear reducers, gear racks, removable chains, pulleys and pulleys, planetary gearboxes, timing pulleys, bushings, etc. We offer customization and processing services, along with laser printing of logos. Our products are highly regarded by customers worldwide, and we provide high-quality products at competitive prices. We welcome customers to customize with pictures and samples.

Q&A

Q: What is a PTO Shaft?

A: A PTO Shaft is a mechanical device that connects an agricultural tractor or other vehicle's power source to a variety of attachments or separate machines.

Q: What are the types of PTO Shaft?

A: The three main types of PTO shafts are standard PTO shafts, telescoping PTO shafts, and constant velocity PTO shafts.

Q: What are the advantages of PTO Shaft?

A: The advantages of PTO shaft include flexibility to match specific needs, customizable according to different specifications, ability to operate under high-speed conditions and maintain stability, and designed with a universal joint, which allows for flexible rotation and better power transmission.

Q: What are the applications of PTO Shaft?

A: PTO shafts are commonly used in various applications, including agricultural machinery, industrial equipment, transportation equipment, and solar tracking systems.

Q: How to maintain a PTO Shaft?

A: To maintain a PTO shaft, regularly check and lubricate the shaft and universal joint. Replace any worn or damaged parts and ensure that the protective cover is in good condition.

Q: What is HZPT Group?

A: HZPT Group is a leading supplier of various transmission components, including agricultural gearboxes, power output shafts, sprockets, hydraulic couplings, worm gear reducers, gear racks, removable chains, pulleys and pulleys, planetary gearboxes, timing pulleys, bushings, etc.

About us

We guarantee top-quality products at the best prices in China! Special orders are welcome, and if you’re interested in any of our products, feel free to reach out for more detailed information. We ensure our products are safe, high-quality, and reasonably priced. Please contact us as soon as possible if you’d like to learn more. We’re eager to cooperate with you!

A large portion of our products is exported to Europe and the Americas, with both standard and custom options available. We can manufacture according to your drawings or samples, using standard materials or as per your specific requirements. Choosing us means choosing reliability.

Materials Available

1. Stainless Steel: SS201, SS303, SS304, SS316, SS416, SS420

2. Steel:C45(K1045), C46(K1046),C20

3. Brass:C36000 ( C26800), C37700 ( HPb59), C38500( HPb58), C27200(CuZn37), C28000(CuZn40)

4. Bronze: C51000, C52100, C54400, etc

5. Iron: 1213, 12L14,1215

6. Aluminum: Al6061, Al6063

7.OEM according to your request

Surface Treatment

Annealing, natural canonization, heat treatment, polishing, nickel plating, chrome plating, zinc plating,yellow passivization, gold passivization, satin, Black surface painted etc.

Processing Method

CNC machining, punch,turning, milling, drilling, grinding, broaching, welding and assembly

QC & Certificate

Technicians self-check in production,final-check before package by professional Quality inspector

ISO9001:2008 , ISO14001:2001,ISO/TS 16949:2009

Package & Lead Time

Size: Drawings

Wooden Case/Container and pallet, or as per customized specifications.

15-25days samples. 30-45days offcial order

Port: Shanghai/Ningbo port

Industries We Service