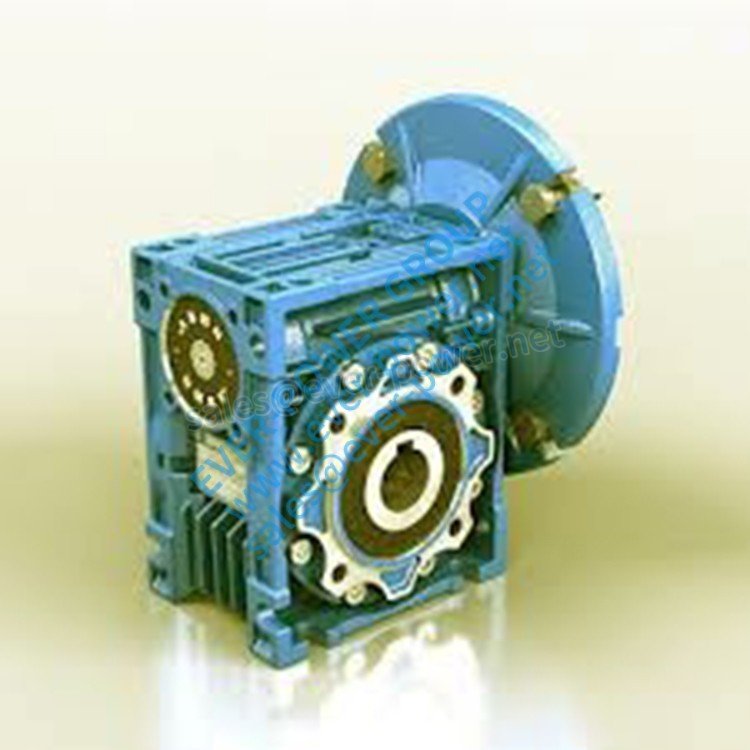

worm gear unit

Worm Gear Unit: High Quality and Efficient Power Transmission Solution

Worm gear units are widely used in various industrial applications due to their efficiency, compact size, and excellent load-carrying capacity. HZPT is a trusted name in the industry, offering high-quality worm gear units that deliver outstanding performance even under extreme conditions.

The History of Worm Gears:

Worm gears have been in use for centuries, and they are believed to have originated in ancient Greece and Egypt. Since then, worm gears have been used in various applications, from windmills to heavy machinery. Today, worm gear units are used in almost every industry that requires high torque and precision motion control.

Classification and Advantages of Worm Gear Units:

Worm gear units are classified based on the number of threads on the worm and the orientation of the worm shaft. The most common types are single thread and double thread worm gear units, with either right-hand or left-hand orientation. Worm gear units offer several advantages, including:

- High load-carrying capacity

- Efficient power transmission

- Quiet operation

- Compact size

- Easy installation and maintenance

Materials Used in Worm Gear Units:

HZPT places great importance on the quality of materials used in worm gear units to ensure a long service life and high performance. The housing parts are made of high-quality grey cast iron (EN-GJL-200), while the hollow bosses, from gear unit sizes greater than 100, are made of spheroidal graphite iron (EN-GJS-400-15). Worm shafts are made from 16MnCrS5BG, which is hardened and ground for increased wear resistance. The worm gear unit rims are centrifugally cast solid bronze with nickel additives GzCuSn12Ni, which provides outstanding smooth and emergency running properties.

Installation, Maintenance, and Repair:

Proper installation, maintenance, and repair of worm gear units are crucial to ensuring their optimal performance and long service life. When installing, make sure the shaft alignment is correct, and the lubrication is adequate. Routine maintenance includes checking for leaks, proper lubrication, and wear on gears and bearings. In case of repair, it is recommended to replace the worn-out components promptly to avoid further damage to the unit.

Other Products Offered by HZPT:

Apart from worm gear units, HZPT also supplies various plastic gears used in industry, such as agricultural gearboxes, power output shafts, sprockets, fluid couplings, gears and racks, detachable chains, pulleys and pulleys, planetary gearboxes, timing pulleys, bushings, and more. We are committed to providing high-quality products, favorable prices, and considerate service to our customers. We welcome customers to come to us with their drawings or samples for customization.

Q&A:

- What are the advantages of using a worm gear unit in industrial applications?

- What are the different types of worm gear units available?

- What materials are used in HZPT's worm gear units?

- What is the recommended maintenance procedure for worm gear units?

- What other products does HZPT supply apart from worm gear units?

About us

We guarantee top-quality products at the best prices in China! Special orders are welcome, and if you’re interested in any of our products, feel free to reach out for more detailed information. We ensure our products are safe, high-quality, and reasonably priced. Please contact us as soon as possible if you’d like to learn more. We’re eager to cooperate with you!

A large portion of our products is exported to Europe and the Americas, with both standard and custom options available. We can manufacture according to your drawings or samples, using standard materials or as per your specific requirements. Choosing us means choosing reliability.

Materials Available

1. Stainless Steel: SS201, SS303, SS304, SS316, SS416, SS420

2. Steel:C45(K1045), C46(K1046),C20

3. Brass:C36000 ( C26800), C37700 ( HPb59), C38500( HPb58), C27200(CuZn37), C28000(CuZn40)

4. Bronze: C51000, C52100, C54400, etc

5. Iron: 1213, 12L14,1215

6. Aluminum: Al6061, Al6063

7.OEM according to your request

Surface Treatment

Annealing, natural canonization, heat treatment, polishing, nickel plating, chrome plating, zinc plating,yellow passivization, gold passivization, satin, Black surface painted etc.

Processing Method

CNC machining, punch,turning, milling, drilling, grinding, broaching, welding and assembly

QC & Certificate

Technicians self-check in production,final-check before package by professional Quality inspector

ISO9001:2008 , ISO14001:2001,ISO/TS 16949:2009

Package & Lead Time

Size: Drawings

Wooden Case/Container and pallet, or as per customized specifications.

15-25days samples. 30-45days offcial order

Port: Shanghai/Ningbo port

Industries We Service