Rotary Cutter Gearboxes – Replacement of Omni Code RC-100 Gearbox

The RC-100 rotary cutter gearbox from TEBSA Argentina is a rugged, heavy-duty solution built for tough agricultural jobs. Whether you’re slashing through thick pasture, finishing a lawn, or clearing overgrown fields, this gearbox delivers the power and reliability you need. Designed specifically for rotary cutters, it handles heavy loads and rough conditions with ease—perfect for Argentina’s demanding farmlands like the Pampas. Since 1997, TEBSA has been crafting dependable gear solutions, and the RC-100 carries that legacy with a 100% quality guarantee and a 50% cost edge over original brands.

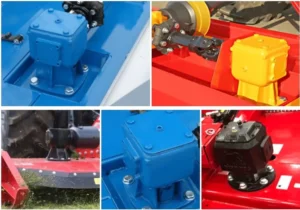

Made with high-strength materials, the RC-100 features a cast iron housing that stands up to impacts, weather, and wear. Inside, its gears—forged from tough steel—ensure smooth speed adjustments and long-lasting performance. What sets it apart? An oil bath lubrication system keeps everything running smoothly, cutting down wear and stretching the gearbox’s life. Plus, a wide-angle input yoke makes hooking up the PTO shaft a breeze, saving you time when connecting to your tractor.

This gearbox takes the high-speed spin of a tractor’s PTO shaft and dials it down to a steady output for cutting blades, adding torque where it counts. It’s a workhorse for farmers and landscapers in Argentina and beyond, built to tackle a range of tasks with efficiency and strength.

Technical Features and Specifications of the RC-100 Rotary Cutter Gearbox

The RC-100 isn’t just tough—it’s smartly engineered for real-world farm use. Its cast iron shell shrugs off the knocks and bumps of daily work, while the high-strength steel gears inside handle torque demands without flinching. The oil bath system is a standout: it keeps the gears coated in lubricant, reducing friction and heat even during long hours of cutting soybean fields or wheat patches in Argentina. That means less downtime and fewer repairs.

Installation? Simple. The wide-angle yoke fits a 1 3/8-inch 6-spline input shaft, locking onto your tractor’s PTO fast. The output shaft, with 15 splines, drives blades at a 1:1.46 ratio—perfect for balancing speed and power. It’s reverse-rotating, so it pairs seamlessly with finishing mowers, rotary cutters, and slashers. Whether you’re running a 50 HP setup or pushing it to 150 HP, this gearbox holds up.

Here’s a breakdown of the specs:

| Model: | EPT-RC100 Rotary Cutter Gearbox |

| Horsepower: | 50-150 HP |

| Input Shaft: | 1 3/8 in 6 A Spline |

| Output Shaft: | 15 Spline |

| Ratio: | 1:1.46 |

| Rotation: | Reverse |

| Applications | Finishing Mowers Rotary Cutters Rotary Slashers |

Need more details? The RC-100 weighs in at a solid but manageable size, and its oil capacity keeps it humming through long days. TEBSA’s engineering team—ready to assist within 24 hours—backs every unit, ensuring you’ve got support when you need it.

Applications and Benefits in Agricultural Settings

The RC-100 rotary cutter gearbox shines in Argentina’s agricultural heartlands. Picture it churning through thick grass near Buenos Aires or slicing overgrown scrub in Córdoba—it’s built for that. Farmers use it on finishing mowers to tidy up pastures, on rotary cutters to clear land for soybean planting, and on slashers to prep fields for harvest. Its 50-150 HP range makes it versatile enough for small tractors or bigger rigs, handling everything from light trimming to heavy slashing.

Why choose the RC-100? First, efficiency. That 1:1.46 ratio slows PTO speed just right, giving blades the torque to cut cleanly without bogging down. Second, durability. The cast iron housing and steel gears laugh off rocks, mud, and Argentina’s unpredictable weather. Third, cost. TEBSA’s 50% savings over original parts mean you’re getting premium performance without the premium price tag.

Here’s a quick look at how it stacks up for different jobs:

| Application | Key Benefit | Ideal Use Case |

|---|---|---|

| Finishing Mowers | Smooth, even cuts | Lawn maintenance near rural homes |

| Rotary Cutters | High torque output | Clearing soybean or wheat fields |

| Rotary Slashers | Rugged durability | Tackling overgrown scrubland |

The oil bath lubrication deserves a shoutout here. By keeping gears slick, it cuts wear—crucial when you’re running long hours in dusty, dry conditions. Add the easy PTO hookup, and you’re back in the field faster. For Argentine farmers looking to boost productivity without breaking the bank, this gearbox is a game-changer.

Safety’s another perk. With TEBSA’s quality commitment, you’re less likely to deal with breakdowns that could stall your work or worse. It’s a reliable partner for keeping your operation moving, whether you’re prepping land in the Pampas or maintaining ditches near Rosario.

Maintenance Tips and Why TEBSA Stands Out

Keeping the RC-100 in top shape isn’t hard, but it pays off. Check the oil level every few weeks—make sure it’s clean and topped up. Use a high-quality gear oil (SAE 80W-90 works well) to keep that bath lubrication doing its job. Give the input shaft a quick clean and a dab of grease now and then to keep power flowing smoothly. Look over the housing for cracks or leaks, especially after a rough day of cutting. And make sure the gearbox and cutter are aligned—misalignment can wear out gears fast.

If something feels off, TEBSA’s team is a call away, responding within 24 hours. That’s part of the deal with us—support you can count on. Regular care like this stretches the RC-100’s life, saving you from costly replacements down the road.

So why TEBSA? We’ve been in the game since 1997, perfecting gearboxes for farms across Argentina and beyond. Our 100% quality promise isn’t just talk—every RC-100 gets tested to handle the toughest jobs. And at 50% less than big-name originals, you’re getting the same grit for less cash. Based in Argentina, we know what local farmers need: gear that works as hard as they do, from soybean harvests to pasture clearing.

About TEBSA and Our Agricultural Gearbox Range

TEBSA, Argentina’s go-to gearbox maker since 1997, brings decades of know-how to every product. We’re not just about the RC-100—we’ve got a full lineup of agricultural gearboxes to fit your needs. Think fertilizer spreader gearboxes for even nutrient distribution, lawn mower gearboxes for crisp cuts, or post hole digger gearboxes for fast fencing. We also offer rotary tiller gearboxes, corn header gearboxes, feed mixer gearboxes, flail mower gearboxes, round baler gearboxes, and more. Each one’s built with the same care—cast iron, steel gears, and processes like forging and heat treatment.

Looking for a rotary cutter gearbox in Argentina? Or maybe a PTO shaft to match? We’ve got you covered with options from 40 HP up to 150 HP, all at prices that beat the competition. Contact us today—our team’s ready to help within 24 hours, whether you’re in Buenos Aires or the Pampas.

About us

We guarantee top-quality products at the best prices in China! Special orders are welcome, and if you’re interested in any of our products, feel free to reach out for more detailed information. We ensure our products are safe, high-quality, and reasonably priced. Please contact us as soon as possible if you’d like to learn more. We’re eager to cooperate with you!

A large portion of our products is exported to Europe and the Americas, with both standard and custom options available. We can manufacture according to your drawings or samples, using standard materials or as per your specific requirements. Choosing us means choosing reliability.

Materials Available

1. Stainless Steel: SS201, SS303, SS304, SS316, SS416, SS420

2. Steel:C45(K1045), C46(K1046),C20

3. Brass:C36000 ( C26800), C37700 ( HPb59), C38500( HPb58), C27200(CuZn37), C28000(CuZn40)

4. Bronze: C51000, C52100, C54400, etc

5. Iron: 1213, 12L14,1215

6. Aluminum: Al6061, Al6063

7.OEM according to your request

Surface Treatment

Annealing, natural canonization, heat treatment, polishing, nickel plating, chrome plating, zinc plating,yellow passivization, gold passivization, satin, Black surface painted etc.

Processing Method

CNC machining, punch,turning, milling, drilling, grinding, broaching, welding and assembly

QC & Certificate

Technicians self-check in production,final-check before package by professional Quality inspector

ISO9001:2008 , ISO14001:2001,ISO/TS 16949:2009

Package & Lead Time

Size: Drawings

Wooden Case/Container and pallet, or as per customized specifications.

15-25days samples. 30-45days offcial order

Port: Shanghai/Ningbo port

Industries We Service