Rotary Mower Gearbox – Replacement of Comer Code LF-125J

The LF-125J rotary mower gearbox, engineered by TEBSA in Argentina, is a vital component that links a mower’s engine to its cutting blades, ensuring smooth power transfer for efficient operation. Since 1997, TEBSA has built tough, dependable agricultural gearboxes backed by a 100% quality guarantee, and the LF-125J is no exception. Designed for durability, it keeps rotary mowers running strong across Argentina’s fields, from soybean farms in Córdoba to wheat plains in the Pampas.

This gearbox thrives in demanding tasks like lawn maintenance, pasture trimming, and crop residue management. Its rugged build, crafted with alloy steel and precision forging, resists wear even in tough conditions. Regular checks—oil levels, cleaning, lubrication, and inspections for leaks—keep it humming along. By following TEBSA’s maintenance tips, farmers avoid breakdowns and extend their mower’s life, saving up to 50% compared to other brands.

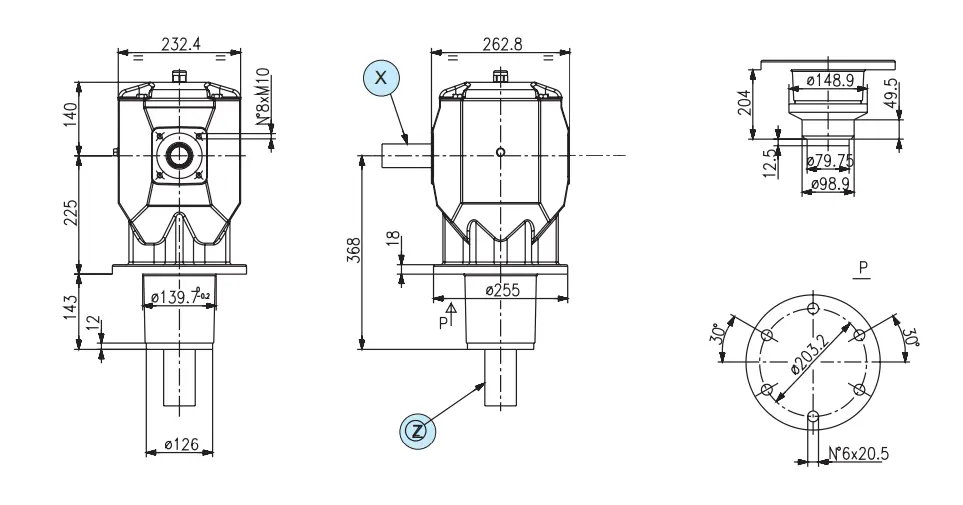

Rotary Mower Gearbox LF-125J Specifications

| i | N1[rpm] | P1[kW] | M2[Nm] | Shaft Type | Input | |

| X | Z | |||||

| 1.77 | 540 | 93.0 | 901 | 1'' 3/4 Z20 | Hub connection | X |

| 1.00 | 1000 | 93.0 | 861 | 1'' 3/4 Z20 | Hub connection | X |

Why the LF-125J Excels in Agricultural Mowing

The LF-125J rotary mower gearbox is a workhorse for Argentina’s agricultural sector, designed to handle the rigors of cutting grass, weeds, and crop stubble. Whether you’re maintaining pastures in Santa Fe or clearing fields in Buenos Aires, this gearbox delivers consistent power to keep blades spinning smoothly. Its versatility suits small farms and large operations alike, making it a go-to for tasks like orchard upkeep, roadside trimming, or vineyard care.

Built with high-strength alloy steel, the LF-125J withstands the vibrations and shocks of daily use. TEBSA’s advanced manufacturing—think forging, carburization, and precision grinding—ensures every unit meets ISO9001-2015 standards. The gearbox’s hub connection and 1¾ Z20 shaft fit most rotary mowers, offering easy setup for Argentine farmers. With torque up to 901 Nm at 540 rpm, it tackles thick grass or dense stubble without bogging down.

Farmers value its efficiency. The LF-125J’s gear ratios (1.77:1 or 1:1) let you match the mower’s speed to your tractor’s PTO, saving fuel and reducing wear. Its compact design keeps weight low at just under 40 kg (estimated), so it won’t strain your equipment. Plus, TEBSA’s 50% cost advantage means you get premium performance without the hefty price tag of imported brands.

Maintenance is straightforward. Check the oil every 50 hours, clean off debris after use, and inspect seals for leaks. TEBSA recommends high-grade gear oil to keep gears running smoothly. A quick lubrication of the input shaft prevents friction damage. These steps ensure the LF-125J lasts for years, even in Argentina’s humid summers or dusty harvest seasons.

| Feature | Benefit |

| Alloy steel construction | Resists wear in tough conditions |

| High torque (901 Nm) | Powers through dense vegetation |

| Flexible gear ratios | Matches tractor PTO for efficiency |

| Easy-to-check oil system | Simplifies maintenance |

Applications and Performance in Argentina’s Fields

The LF-125J shines in Argentina’s diverse farming landscape. It’s a key player in rotary mowers used for cutting alfalfa, clearing maize stubble, or grooming pastures for cattle grazing. In regions like Entre Ríos, where wet soils challenge equipment, its sealed design keeps out dirt and moisture. For drier areas like Mendoza’s vineyards, it handles dusty conditions without overheating.

This gearbox supports a range of mower sizes, from 1.5 to 2.5 meters, making it ideal for both compact tractors and larger setups. Its 93 kW power rating suits most mid-sized tractors common in Argentina, delivering steady blade speed for clean cuts. Farmers switching between crops—say, soybeans to wheat—appreciate its adaptability across tasks like cover crop management or field edging.

Technical highlights include its bevel gear system, which ensures smooth power flow with minimal noise. The hub connection simplifies blade swaps, saving time during busy seasons. TEBSA’s heat treatment process, like carbonitriding, hardens gears to resist pitting, even after thousands of hours. For online buyers searching “rotary mower gearbox for sale in Argentina,” the LF-125J offers proven performance at a budget-friendly price.

Local conditions shape its use. In the Pampas, where flat fields stretch for miles, the LF-125J powers long mowing sessions without faltering. In hilly San Juan, its sturdy build handles uneven terrain. Farmers buying “agricultural gearbox near Buenos Aires” find TEBSA’s quick delivery and 24-hour support a game-changer. Pair it with a PTO shaft from TEBSA, and you’ve got a setup tailored for Argentina’s harvest cycles.

| Application | Why LF-125J Fits |

| Pasture trimming | High torque for thick grass |

| Crop residue cutting | Durable in dusty conditions |

| Vineyard maintenance | Compact for tight rows |

| Roadside mowing | Reliable for long hours |

Maintenance and Long-Term Value

Keeping the LF-125J in top shape is simple, which matters for busy Argentine farmers. Start with oil checks—use a dipstick to confirm levels before long jobs. TEBSA suggests changing oil every 500 hours or annually, whichever comes first, to clear out sludge. Look for leaks around seals; a small drip can signal a worn gasket. Cleaning the gearbox after use prevents grass buildup, especially in humid areas like Rosario.

Lubrication is key. Grease the input shaft monthly to cut friction. If you spot unusual noise or heat, check alignment—misaligned shafts strain gears. TEBSA’s engineering team, available within 24 hours, can guide you through fixes. The LF-125J’s tapered roller bearings reduce wear, but inspect them yearly for smoothness. These steps dodge costly repairs and keep your mower cutting cleanly.

The gearbox’s value shines long-term. Its alloy steel gears, hardened through carburization, resist cracking under Argentina’s variable climates. At 50% less cost than competitors, it’s a smart buy for farmers searching “reliable agricultural gearbox in Argentina.” Online shoppers looking for “rotary mower parts near me” appreciate TEBSA’s fast shipping and clear specs. The LF-125J’s design cuts downtime, letting you focus on planting or harvesting.

For heavy users, consider pairing it with TEBSA’s PTO shafts, forged for strength and balanced for minimal vibration. This combo boosts mower life, whether you’re clearing fields in La Pampa or prepping land in Tucumán. With proper care, the LF-125J delivers years of service, making it a favorite for those seeking “durable farm gearbox for sale.”

About TEBSA and Our Agricultural Solutions

TEBSA, based in Argentina since 1997, is your trusted partner for agricultural gearboxes, offering a 100% quality guarantee and a 50% cost edge over original brands. Our ISO9001-2015 certification reflects our commitment to precision, from forging to final assembly. With a talented engineering team responding in 24 hours, we support farmers across Buenos Aires, Mendoza, and beyond.

Beyond the LF-125J, we supply gearboxes for fertilizer spreaders, post hole diggers, rotary tillers, and flail mowers. Our PTO shafts, couplings, and hydraulic cylinders suit Argentina’s diverse crops—soybeans, wheat, maize, and more. Whether you need a “rotary mower gearbox in Córdoba” or a “farm equipment gearbox online,” TEBSA delivers durability and value. Contact us to explore our full range and keep your farm running strong.

About us

We guarantee top-quality products at the best prices in China! Special orders are welcome, and if you’re interested in any of our products, feel free to reach out for more detailed information. We ensure our products are safe, high-quality, and reasonably priced. Please contact us as soon as possible if you’d like to learn more. We’re eager to cooperate with you!

A large portion of our products is exported to Europe and the Americas, with both standard and custom options available. We can manufacture according to your drawings or samples, using standard materials or as per your specific requirements. Choosing us means choosing reliability.

Materials Available

1. Stainless Steel: SS201, SS303, SS304, SS316, SS416, SS420

2. Steel:C45(K1045), C46(K1046),C20

3. Brass:C36000 ( C26800), C37700 ( HPb59), C38500( HPb58), C27200(CuZn37), C28000(CuZn40)

4. Bronze: C51000, C52100, C54400, etc

5. Iron: 1213, 12L14,1215

6. Aluminum: Al6061, Al6063

7.OEM according to your request

Surface Treatment

Annealing, natural canonization, heat treatment, polishing, nickel plating, chrome plating, zinc plating,yellow passivization, gold passivization, satin, Black surface painted etc.

Processing Method

CNC machining, punch,turning, milling, drilling, grinding, broaching, welding and assembly

QC & Certificate

Technicians self-check in production,final-check before package by professional Quality inspector

ISO9001:2008 , ISO14001:2001,ISO/TS 16949:2009

Package & Lead Time

Size: Drawings

Wooden Case/Container and pallet, or as per customized specifications.

15-25days samples. 30-45days offcial order

Port: Shanghai/Ningbo port

Industries We Service