Feed Mixer Machines Gearboxes – Replacement of Comer Code PGA-1602

The Feed Mixer Gearbox PGA-1602, crafted by TEBSA in Argentina, is a robust solution for blending animal feed in the agricultural sector. Designed to mix grains, supplements, and other ingredients into uniform livestock feed, this gearbox ensures consistent nutrition for cattle, poultry, and more. Since 1997, TEBSA has been a trusted manufacturer, offering a 100% quality guarantee and a 50% cost advantage over original brands. The PGA-1602 is engineered for high-torque, heavy-duty feed mixing, making it an ideal replacement for Comer Code PGA-1602 gearboxes.

This gearbox powers the mixing chamber by transferring energy from the input shaft with precision. Its durable build, using alloy steel and advanced forging techniques, handles the intense demands of Argentina’s livestock farms, from the Pampas to Córdoba. With a compact design and a specialized bearing for direct screw spindle connection, it simplifies setup and boosts efficiency. Whether you’re running a single mixer (10–14 cubic meters) or a double mixer (16–24 cubic meters), the PGA-1602 delivers reliable performance for feed preparation.

Key Features and Benefits of the PGA-1602 Feed Mixer Gearbox

The PGA-1602 stands out in Argentina’s agricultural landscape for its durability and efficiency. Here’s why it’s a top choice for feed mixing:

High Torque Capacity: With a maximum output torque of 15,700 Nm (1,570 daNm), it tackles dense feed mixes, ensuring smooth blending even under heavy loads. This makes it perfect for large-scale farms in Buenos Aires or Santa Fe.

Durable Construction: Built with alloy steel and processed through forging and carburization, the gearbox resists wear and tear in tough conditions, like Argentina’s humid summers or dusty plains.

Simplified Installation: The integrated bearing for screw spindle connection eliminates the need for separate bearing kits, saving time and reducing costs for farmers.

Versatile Application: Suited for mixing wagons of various sizes, it supports single mixers (10–14 m³) and double mixers (16–24 m³), adapting to diverse livestock operations.

Cost-Effective Solution: TEBSA’s 50% cost advantage over Comer originals, paired with a 100% quality guarantee, makes the PGA-1602 a smart investment for feed mixer machine operators.

Easy Maintenance: Designed for straightforward upkeep, it uses 90EP oil (ordered separately) and comes with replaceable parts, backed by TEBSA’s 24-hour response team.

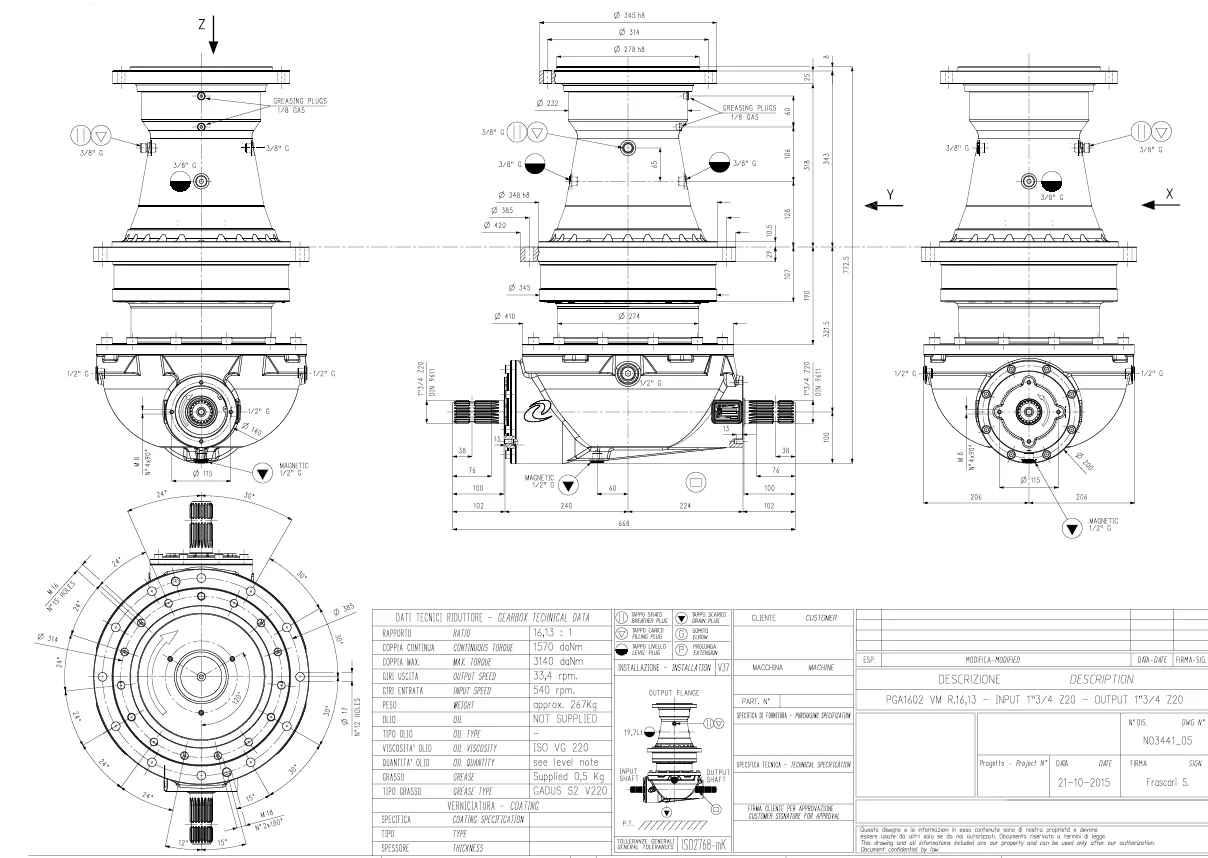

Technical Specifications of the PGA-1602 Feed Mixer Gearbox

The PGA-1602 is engineered for precision and power. Below are its detailed specifications:

| Description | Feed Mixer Gearboxes - Replacement for Comer Code PGA-1602 |

|---|---|

| Specifications | Has a special bearing complete where the screw spindle can be directly connected. |

| Benefits | No separate bearing complete required for the winch |

| Application |

|

| Consists of |

|

| Model | PGA 1602 |

| Max. output rotation speed | 29 r/min |

| Max. output torque | 15700 nm |

| Max. output torque | 1570 daNm |

| Contains oil | No |

| Oil SAE viscosity grade | 90EP |

| Weight | 265 kg |

| Gear ratio | 16.1:1 |

| Input power KW / HP Reducing | 88.7 kW/HP |

| Ratio Reducing | 16,2:1 |

| Shaft type | 2 x 1.3/4 (Z20) |

Dimensions of the PGA-1602 Feed Mixer Gearbox

Applications and Performance in Argentine Agriculture

The PGA-1602 gearbox is a cornerstone for livestock feed preparation in Argentina, where agriculture drives the economy. It powers mixing wagons that blend grains, silage, and supplements into balanced feed for cattle, dairy cows, and poultry. Its ability to handle high torque makes it a reliable choice for farms in regions like Buenos Aires, Santa Fe, and Córdoba, where large-scale livestock operations thrive.

This gearbox excels in mixing wagons for single mixers (10–14 cubic meters) and double mixers (16–24 cubic meters), catering to both small and large farms. For example, it supports dairy farms producing feed for high-yield cows or beef operations preparing rations for grass-fed cattle in the Pampas. The 16.1:1 gear ratio and 29 r/min output speed ensure thorough mixing without overloading the system, even with dense ingredients like wet silage or protein concentrates.

The PGA-1602’s robust design, featuring alloy steel and carburized gears, withstands Argentina’s varied climates—from humid summers to dusty dry seasons. Its shaft type (2 x 1.3/4 Z20) ensures secure PTO connection, critical for continuous operation during peak feeding seasons. Farmers can rely on TEBSA’s engineering, backed by ISO9001-2015 certification, to keep their feed mixers running smoothly.

To highlight its versatility, here’s a breakdown of typical applications:

| Application | Mixer Size | Ideal Use Case |

|---|---|---|

| Single Mixer | 10–14 m³ | Small to medium dairy farms in Córdoba |

| Double Mixer | 16–24 m³ | Large beef farms in the Pampas |

| Custom Feed Prep | Varies | Specialized poultry feed in Santa Fe |

Maintenance and Operational Tips for Longevity

To keep the PGA-1602 performing at its best, regular maintenance is key. TEBSA designs this gearbox for easy upkeep, ensuring minimal downtime for Argentine farmers. Here are practical tips:

Check Oil Levels: Use 90EP oil (purchased separately) and inspect levels every 100 hours of operation. Change oil every 1,000 hours or annually to prevent contamination.

Inspect for Wear: Look for leaks or damage on the gearbox housing, especially after heavy use in dusty conditions like those in Argentina’s interior.

Lubricate Shafts: Keep the 2 x 1.3/4 Z20 shafts greased to ensure smooth PTO engagement and reduce friction.

Monitor Alignment: Ensure the gearbox and mixing wagon are properly aligned to avoid strain on gears, which can lead to premature wear.

Clean Regularly: Remove feed residue or debris from the gearbox exterior to prevent corrosion, particularly in humid regions like Buenos Aires.

TEBSA’s 24-hour response team is ready to assist with parts or technical queries, ensuring your feed mixer stays operational. The gearbox’s 265 kg weight makes it sturdy yet manageable for installation, and its lack of pre-filled oil allows farmers to choose the best lubricant for their conditions.

For optimal performance, pair the PGA-1602 with a PTO shaft designed for feed mixers. TEBSA’s forging and heat treatment processes, like carbonitriding, enhance gear durability, reducing maintenance costs over time. This gearbox’s 88.7 kW/HP input power capacity supports high-output tractors, common in Argentina’s modern farms.

Why Choose TEBSA for Feed Mixer Gearboxes in Argentina

Since 1997, TEBSA has been a leading manufacturer of agricultural gearboxes in Argentina, delivering reliable, cost-effective solutions to farmers and industrial operators. Based in Argentina, we understand the unique demands of local agriculture, from soybean fields to cattle ranches. Our PGA-1602 gearbox reflects our commitment to quality, backed by ISO9001-2015 certification and a 100% quality guarantee on every order.

Our 50% cost advantage over original brands like Comer makes TEBSA a smart choice for budget-conscious farmers without compromising performance. With a skilled engineering team responding within 24 hours, we ensure your equipment keeps running. The PGA-1602, with its alloy steel construction and advanced manufacturing (forging, carburization, and grinding), is built to last in Argentina’s toughest conditions.

Beyond feed mixer gearboxes, TEBSA offers a wide range of agricultural solutions:

Rotary Cutter Gearboxes: Like the RC-61, perfect for pasture management.

Fertilizer Spreader Gearboxes: For precise nutrient application in soybean or wheat fields.

Post Hole Digger Gearboxes: Ideal for fencing on large ranches.

Rotary Tiller Gearboxes: For soil preparation in Argentina’s fertile plains.

PTO Shafts: Compatible with various farm implements for seamless power transfer.

Explore our full catalog at agricultural-gear-boxes.com or contact us to discuss your needs. TEBSA is your trusted partner for agricultural gearboxes in Argentina, delivering durability, efficiency, and value since 1997.

About us

We guarantee top-quality products at the best prices in China! Special orders are welcome, and if you’re interested in any of our products, feel free to reach out for more detailed information. We ensure our products are safe, high-quality, and reasonably priced. Please contact us as soon as possible if you’d like to learn more. We’re eager to cooperate with you!

A large portion of our products is exported to Europe and the Americas, with both standard and custom options available. We can manufacture according to your drawings or samples, using standard materials or as per your specific requirements. Choosing us means choosing reliability.

Materials Available

1. Stainless Steel: SS201, SS303, SS304, SS316, SS416, SS420

2. Steel:C45(K1045), C46(K1046),C20

3. Brass:C36000 ( C26800), C37700 ( HPb59), C38500( HPb58), C27200(CuZn37), C28000(CuZn40)

4. Bronze: C51000, C52100, C54400, etc

5. Iron: 1213, 12L14,1215

6. Aluminum: Al6061, Al6063

7.OEM according to your request

Surface Treatment

Annealing, natural canonization, heat treatment, polishing, nickel plating, chrome plating, zinc plating,yellow passivization, gold passivization, satin, Black surface painted etc.

Processing Method

CNC machining, punch,turning, milling, drilling, grinding, broaching, welding and assembly

QC & Certificate

Technicians self-check in production,final-check before package by professional Quality inspector

ISO9001:2008 , ISO14001:2001,ISO/TS 16949:2009

Package & Lead Time

Size: Drawings

Wooden Case/Container and pallet, or as per customized specifications.

15-25days samples. 30-45days offcial order

Port: Shanghai/Ningbo port

Industries We Service