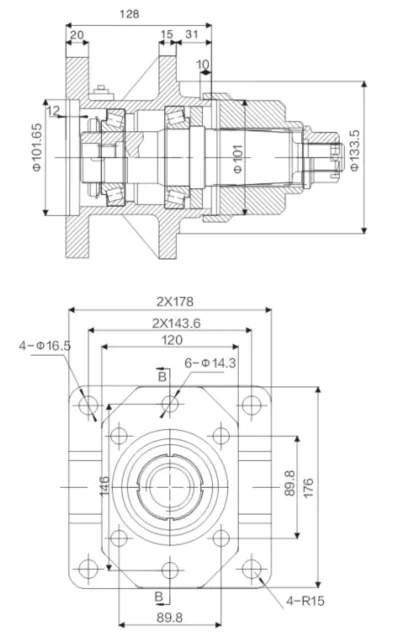

Hydraulic Drive Spindle EP-MDH-40 for Gearbox

The Hydraulic Drive Spindle EP-MDH-40, also known as a bearing housing, is a critical component of agricultural gearboxes, designed to deliver robust performance in demanding applications. Manufactured by TEBSA, Argentina’s trusted supplier since 1997, this spindle ensures seamless power transmission in machinery used across agriculture, construction, forestry, metal processing, and environmental protection. With a 100% quality guarantee and a 50% cost advantage over original brands, TEBSA’s EP-MDH-40 is built for durability and efficiency in Argentina’s diverse industries, from the Pampas plains to the industrial hubs of Buenos Aires and Córdoba.

Crafted with precision, the EP-MDH-40 uses high-grade materials like 20CrMnTi alloy steel for gears and 42CrMo alloy steel for shafts, processed through advanced techniques such as tempering, cementing, and quenching. Its cast iron or ductile iron housing withstands harsh conditions, making it ideal for heavy-duty tasks like soybean harvesting or construction site preparation. With a compact design, low noise (60-68dB), and high efficiency (98%), this spindle meets the needs of farmers, contractors, and industrial operators in Argentina.

Technical Specifications of the EP-MDH-40 Hydraulic Drive Spindle

The EP-MDH-40 is engineered for precision and reliability. Below are its key specifications:

| Housing Material | Cast Iron/Ductile Iron |

| Housing Hardness | HBS190-240 |

| Gear Material | 20CrMnTi Alloy Steel |

| Surface Hardness of Gears | HRC58~62 |

| Gear Core Hardness | HRC33~40 |

| Input/Output Shaft Material | 42CrMo Alloy Steel |

| Input/Output Shaft Hardness | HRC25~30 |

| Machining Precision of Gears | Accurate Grinding, 6~5 Grade |

| Lubricating Oil | GB L-CKC220-460, Shell Omala220-460 |

| Heat Treatment | Tempering, Cementing, Quenching |

| Efficiency | 98% |

| Noise (MAX) | 60~68dB |

| Vibration | ≤20µm |

| Backlash | ≤20Arcmin |

| Brand of Bearings | China Top Brand Bearing, HRB/LYC/ZWZ/C&U, or SKF, FAG, INA, NSK |

| Brand of Oil Seal | NAK (Taiwan) or Other Brands Requested |

Applications and Benefits of the EP-MDH-40 Hydraulic Drive Spindle

The EP-MDH-40 is a versatile component tailored for multiple industries in Argentina, delivering unmatched performance in demanding environments. Its applications span agriculture (e.g., soybean and corn harvesting in the Pampas), construction (site preparation in Buenos Aires), forestry (timber processing in Misiones), metal processing (industrial workshops in Rosario), and environmental protection (waste management systems). Below are its key benefits:

High Durability: The 20CrMnTi alloy steel gears, with surface hardness of HRC58-62, resist wear even in Argentina’s humid subtropical climates or dusty plains.

Efficient Power Transfer: With 98% efficiency, it minimizes energy loss, reducing fuel costs for tractors and machinery.

Low Maintenance: Precision-ground gears (6-5 grade) and NAK oil seals keep maintenance simple, backed by TEBSA’s 24-hour technical support.

Quiet Operation: Noise levels of 60-68dB ensure a comfortable work environment, crucial for long hours in the field.

Cost Savings: TEBSA’s 50% cost advantage makes the EP-MDH-40 an affordable upgrade for Argentine farmers and contractors.

The EP-MDH-40 integrates seamlessly into agricultural gearboxes, enhancing the performance of machinery like rotary cutters, flail mowers, and tillers. Its robust design handles high torque and heavy loads, making it a reliable choice for tasks like clearing pastureland or processing metal components.

Application-Specific Use Cases

To illustrate its versatility, here’s how the EP-MDH-40 serves different sectors:

| Industry | Application | Benefit |

|---|---|---|

| Agriculture | Soybean harvesting in Córdoba | High torque for heavy crop cutting |

| Construction | Site clearing in Buenos Aires | Durable housing resists debris impact |

| Forestry | Timber processing in Misiones | Low vibration for precision cutting |

Technical Features and Maintenance of the EP-MDH-40

The EP-MDH-40 stands out for its advanced engineering, tailored to meet the needs of Argentine industries. Its key technical features include:

Material Excellence: Gears made from 20CrMnTi alloy steel and shafts from 42CrMo ensure strength and corrosion resistance, vital for Argentina’s varied climates.

Precision Engineering: Accurate grinding (6-5 grade) and low backlash (≤20Arcmin) deliver smooth operation, reducing wear on connected components.

Heat Treatment: Processes like cementing and quenching enhance gear hardness (HRC58-62) and core toughness (HRC33-40), ideal for high-load tasks.

Top-Tier Components: Bearings from trusted brands like SKF, FAG, or China’s HRB/LYC, paired with NAK oil seals, ensure long-term reliability.

Lubrication: Compatible with GB L-CKC220-460 or Shell Omala220-460 oils, maintaining performance in extreme conditions.

To keep the EP-MDH-40 in top shape, follow these maintenance tips:

Regular Inspections: Check for oil leaks or housing damage every 500 hours of operation.

Oil Changes: Replace lubricating oil every 1,000 hours or410~420 hours, using TEBSA-approved oils like Shell Omala220-460.

Bearing Checks: Inspect bearings for wear during annual maintenance to prevent unexpected downtime.

Alignment: Ensure proper alignment with the gearbox to avoid vibration or gear wear.

Cleaning: Keep the spindle free of debris, especially in dusty regions like the Pampas.

By following these steps, Argentine operators can extend the EP-MDH-40’s lifespan, ensuring reliable performance for years.

Maintenance Schedule

For clarity, here’s a recommended maintenance schedule:

| Task | Frequency |

|---|---|

| Inspect for leaks/damage | Every 500 hours |

| Change lubricating oil | Every 1,000 hours |

| Check bearings | Annually |

About TEBSA and Our Agricultural Solutions

Since 1997, TEBSA, based in Argentina, has been a leading manufacturer of agricultural and industrial components, delivering reliable, cost-effective solutions worldwide. Our commitment to a 100% quality guarantee, 50% cost savings compared to original brands, and a responsive engineering team (with 24-hour feedback) makes us a trusted partner for farmers, contractors, and industrial operators. Certified under ISO9001-2015, we leverage advanced manufacturing processes like forging, heat treatment, and precision grinding to produce durable products tailored to Argentina’s unique needs, from soybean fields in Córdoba to construction sites in Buenos Aires.

In addition to the Hydraulic Drive Spindle EP-MDH-40, TEBSA offers a wide range of agricultural gearboxes and components, including:

Rotary Cutter Gearboxes: Like the RC-61, ideal for heavy-duty cutting in pasture management.

Fertilizer Spreader Gearboxes: For precise distribution in crop farming.

Flail Mower Gearboxes: For versatile mowing in Argentina’s varied terrains.

Post Hole Digger Gearboxes: For efficient fencing and planting.

PTO Shafts: For reliable power transfer in tractors and implements.

Our products are designed to withstand Argentina’s challenging environments, from humid subtropical regions to arid plains, ensuring maximum productivity and safety. Contact TEBSA today to explore our full catalog or request a quote for the EP-MDH-40 or other solutions.

About us

We guarantee top-quality products at the best prices in China! Special orders are welcome, and if you’re interested in any of our products, feel free to reach out for more detailed information. We ensure our products are safe, high-quality, and reasonably priced. Please contact us as soon as possible if you’d like to learn more. We’re eager to cooperate with you!

A large portion of our products is exported to Europe and the Americas, with both standard and custom options available. We can manufacture according to your drawings or samples, using standard materials or as per your specific requirements. Choosing us means choosing reliability.

Materials Available

1. Stainless Steel: SS201, SS303, SS304, SS316, SS416, SS420

2. Steel:C45(K1045), C46(K1046),C20

3. Brass:C36000 ( C26800), C37700 ( HPb59), C38500( HPb58), C27200(CuZn37), C28000(CuZn40)

4. Bronze: C51000, C52100, C54400, etc

5. Iron: 1213, 12L14,1215

6. Aluminum: Al6061, Al6063

7.OEM according to your request

Surface Treatment

Annealing, natural canonization, heat treatment, polishing, nickel plating, chrome plating, zinc plating,yellow passivization, gold passivization, satin, Black surface painted etc.

Processing Method

CNC machining, punch,turning, milling, drilling, grinding, broaching, welding and assembly

QC & Certificate

Technicians self-check in production,final-check before package by professional Quality inspector

ISO9001:2008 , ISO14001:2001,ISO/TS 16949:2009

Package & Lead Time

Size: Drawings

Wooden Case/Container and pallet, or as per customized specifications.

15-25days samples. 30-45days offcial order

Port: Shanghai/Ningbo port

Industries We Service