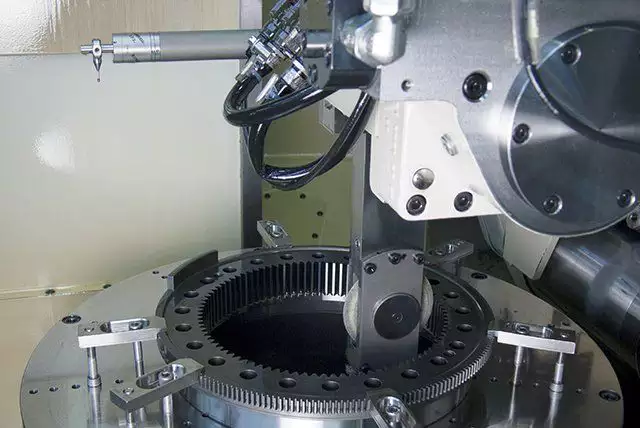

Ring Gears

Since 1997, TEBSA Argentina has crafted high-precision ring gears for agriculture, automotive, and industrial machinery. Built with alloy steel and advanced forging, our ISO9001-2015 certified gears deliver durability and performance, from Pampas harvesters to Buenos Aires factories. Enjoy a 50% cost advantage over original brands and a 100% quality guarantee. Explore internal ring gears, slewing bearings, and custom designs tailored for soybean fields, construction equipment, or automotive systems. Contact our team—available within 24 hours—for reliable solutions across Argentina.

Power Your Machinery with TEBSA’s Ring Gears Today

Ready to upgrade your agricultural or industrial equipment? Discover TEBSA’s precision ring gears, trusted across Argentina since 1997. With a 50% cost advantage and 100% quality guarantee, our alloy steel gears are built for soybean harvesters, automotive systems, and more. Contact our Buenos Aires team—available within 24 hours—for a custom quote or explore our range below!

Material-Based Ring Gears

Alloy Steel Internal Ring Gear

Stainless Steel Ring Gear

Metal Internal Gear

Steel Internal Gear

Plastic Internal Gear

Application-Based Ring Gears

Automotive Internal Gear

Aircraft Internal Gear

Flywheel Ring Gear

Industrial Internal Gear

Specialized Gear Types

Internal Spur Gear

Involute Internal Gear

Planetary Ring Gear

Applied Scenarios for Ring Gears

Ring Gears in Agricultural Machinery

TEBSA’s ring gears, like alloy steel internal and planetary types, power Argentina’s agricultural machinery, from tractors in Córdoba to harvesters in the Pampas. These gears drive transmissions and cutting systems, handling tough soybean and wheat fields with ease. With a 50% cost advantage and 100% quality guarantee since 1997, TEBSA ensures durability and affordability for farmers.

Ring Gears in Automotive Systems

In Argentina’s automotive sector, TEBSA’s flywheel and involute internal ring gears are vital for differentials, starter motors, and transmissions in vehicles from Buenos Aires trucks to Mendoza cars. Offering ISO9001-2015 certified quality and 24-hour support, our gears deliver reliable performance at half the cost of original brands.

Why Choose us

Since 1997, TEBSA has been Argentina’s trusted manufacturer of high-precision ring gears, delivering unmatched quality and value. Our ISO9001-2015 certified production ensures every gear, from alloy steel to planetary designs, meets rigorous standards with a 100% quality guarantee. With a 50% cost advantage over original brands, we provide durable, reliable solutions for agriculture, automotive, and industrial applications without breaking your budget. Our expert engineering team responds within 24 hours, offering tailored support for custom designs or technical queries. Whether you’re powering soybean harvesters in the Pampas or machinery in Buenos Aires, TEBSA combines decades of expertise, competitive pricing, and fast service to keep your operations running smoothly. Choose TEBSA—your partner for excellence in Argentina and beyond.