Agricultural Combine Harvester Reversing Gearbox for Rice Harvesting

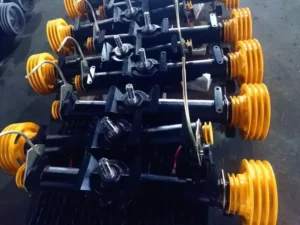

The agricultural combine harvester reversing gearbox is a vital component engineered for large-scale farming equipment, specifically combine harvesters used across Argentina’s fertile plains. Designed by TEBSA, a trusted manufacturer since 1997, this gearbox empowers harvesters to reverse their cutting mechanisms, clearing jams from crops like soybean, wheat, or rice with ease. Built from high-strength steel and precision-crafted for durability, it handles the intense demands of continuous field work, ensuring reliability and a 100% quality guarantee for every order.

This reversing gearbox stands out for its robust gears and bearings, which enable seamless shifts in rotational direction. Integrated into the harvester’s drivetrain, it ensures efficient power transfer from the engine to cutting and threshing systems. By enabling reverse operation, it boosts safety, cuts downtime, and enhances productivity in Argentina’s agricultural heartlands, like Córdoba and Buenos Aires. With TEBSA’s 50% cost advantage over original brands, this gearbox is a smart choice for farmers seeking performance without breaking the bank.

Product Specifications

| Product Name | Short Harvester Reversing for Rice Harvester |

| Material | QT450 for housing, 20CrMnTi for gear shaft |

| Color | Customization |

| Model | EP-1.6Z.03-05 |

| Used | Rice Harvester |

Key Features and Technical Advantages

The TEBSA combine harvester reversing gearbox is crafted to meet the rigorous needs of modern agriculture, particularly in Argentina’s crop-heavy regions. Its standout features include:

- High-Strength Materials: The gearbox uses QT450 cast iron for its housing, offering exceptional resistance to wear and impact. The gear shaft, made from 20CrMnTi, undergoes carburization and heat treatment for added toughness, ensuring it withstands the heavy loads of rice or wheat harvesting.

- Precision Engineering: Advanced manufacturing processes, like gear grinding and teeth hobbing, ensure smooth operation and minimal friction. This precision reduces energy loss, making the gearbox a reliable choice for long hours in the field.

- Seamless Reverse Functionality: Robust bearings and gears allow quick, jerk-free shifts between forward and reverse, critical for clearing blockages in dense crops like rice in Argentina’s Entre Ríos province.

- Customizable Design: Available in various colors and adaptable to different harvester models, it fits seamlessly into your equipment, whether for small rice fields or vast soybean farms.

- Low Maintenance: Designed for easy upkeep, the gearbox supports replaceable seals and straightforward lubrication checks, backed by TEBSA’s 24-hour technical support.

The technical specs reflect TEBSA’s commitment to quality. The EP-1.6Z.03-05 model is optimized for rice harvesters, with a compact design that minimizes drivetrain stress. Its durability and efficiency make it a go-to for farmers aiming to maximize uptime during Argentina’s busy harvest seasons.

Technical Details

| Gear Ratio | 1:1 or customizable |

| Torque Capacity | Up to 2,500 Nm |

| Operating Temperature | -20°C to 80°C |

| Surface Treatment | Blackening, powder coating |

| Weight | Approx. 45 kg |

Applications in Argentine Agriculture

The TEBSA reversing gearbox is a game-changer for combine harvesters operating in Argentina’s diverse agricultural landscape. Its primary role is enabling reverse motion to clear jams caused by tangled crops, a common issue in rice paddies or wheat fields. This functionality is critical in regions like Santa Fe, where rice farming thrives, or the Pampas, known for soybean and corn.

- Rice Harvesters: The EP-1.6Z.03-05 model excels in rice harvesting, where wet, dense stalks often clog machinery. Its quick reverse action minimizes downtime, keeping operations on track.

- Wheat and Soybean Fields: In Argentina’s breadbasket, the gearbox supports heavy-duty harvesters tackling vast fields, ensuring smooth cutting and threshing even under high loads.

- Safety and Efficiency: By reducing the need for manual jam clearing, it lowers risks for operators and boosts field productivity, a key factor for large-scale farms.

- Versatile Integration: Compatible with various combine harvester brands, it’s a flexible solution for farmers upgrading or maintaining their fleets.

Beyond rice, the gearbox supports other crops like corn and sorghum, making it a versatile tool for Argentina’s agribusiness. Its ability to handle continuous operation suits the long harvest seasons, while TEBSA’s cost-effective pricing—50% less than competitors—makes it accessible for local farmers.

Why It Matters in Argentina

Argentina’s agriculture relies on efficient machinery to stay competitive globally. The reversing gearbox addresses common pain points like equipment jams, which can halt work and raise costs. By integrating this component, farmers in Buenos Aires or Mendoza can maintain steady workflows, even in challenging conditions like humid rice fields or dusty wheat plains.

Maintenance and Longevity Tips

To keep the TEBSA reversing gearbox performing at its best, regular care is essential. Here’s how to ensure its longevity:

- Inspect Regularly: Check for leaks, wear, or loose bolts every 50 hours of use, especially during peak harvest seasons.

- Lubrication: Use high-quality gear oil recommended by TEBSA, checking levels monthly and replacing every 500 hours or as needed.

- Clean Components: Clear debris from the housing and shaft to prevent buildup, particularly after working in muddy rice fields.

- Alignment Check: Ensure the gearbox aligns with the drivetrain to avoid uneven wear or vibrations.

- Professional Support: TEBSA’s engineering team responds within 24 hours for troubleshooting or part replacements.

These steps, combined with TEBSA’s ISO9001-2015 certified manufacturing, guarantee a gearbox that lasts through years of heavy use. The use of QT450 and 20CrMnTi, processed with techniques like carbonitriding, further enhances its resistance to Argentina’s demanding field conditions.

About TEBSA and Our Agricultural Solutions

Since 1997, TEBSA has been a leading name in agricultural gearboxes, operating from Argentina as a trusted partner for farmers and industrial clients. Based in Argentina’s agricultural hub, we combine decades of expertise with cutting-edge manufacturing to deliver reliable, cost-effective solutions. Our 100% quality guarantee, 50% cost savings compared to original brands, and 24-hour technical support make us a go-to supplier for agribusinesses across Buenos Aires, Córdoba, and beyond.

Our combine harvester reversing gearbox is just one part of our extensive portfolio. We also offer:

- Rotary Cutter Gearboxes: Like the RC-61, perfect for mowing and heavy cutting.

- Fertilizer Spreader Gearboxes: For precise nutrient distribution in soybean or wheat fields.

- Post Hole Digger Gearboxes: Ideal for fencing or planting in Argentina’s rural areas.

- PTO Shafts: Durable power transfer solutions for various farm implements.

- Flail Mower Gearboxes: Built for tough vegetation clearing.

Each product is crafted with materials like alloy steel, stainless steel, or cast iron, using processes like forging, grinding, and heat treatment to ensure durability. Whether you’re harvesting rice in Entre Ríos or managing pastures in Mendoza, TEBSA’s solutions are designed to keep your operations running smoothly.

Ready to upgrade your combine harvester? Contact TEBSA today for a quote or to learn more about our agricultural gearboxes. Our team is here to help you find the perfect fit for your farm.

About us

We guarantee top-quality products at the best prices in China! Special orders are welcome, and if you’re interested in any of our products, feel free to reach out for more detailed information. We ensure our products are safe, high-quality, and reasonably priced. Please contact us as soon as possible if you’d like to learn more. We’re eager to cooperate with you!

A large portion of our products is exported to Europe and the Americas, with both standard and custom options available. We can manufacture according to your drawings or samples, using standard materials or as per your specific requirements. Choosing us means choosing reliability.

Materials Available

1. Stainless Steel: SS201, SS303, SS304, SS316, SS416, SS420

2. Steel:C45(K1045), C46(K1046),C20

3. Brass:C36000 ( C26800), C37700 ( HPb59), C38500( HPb58), C27200(CuZn37), C28000(CuZn40)

4. Bronze: C51000, C52100, C54400, etc

5. Iron: 1213, 12L14,1215

6. Aluminum: Al6061, Al6063

7.OEM according to your request

Surface Treatment

Annealing, natural canonization, heat treatment, polishing, nickel plating, chrome plating, zinc plating,yellow passivization, gold passivization, satin, Black surface painted etc.

Processing Method

CNC machining, punch,turning, milling, drilling, grinding, broaching, welding and assembly

QC & Certificate

Technicians self-check in production,final-check before package by professional Quality inspector

ISO9001:2008 , ISO14001:2001,ISO/TS 16949:2009

Package & Lead Time

Size: Drawings

Wooden Case/Container and pallet, or as per customized specifications.

15-25days samples. 30-45days offcial order

Port: Shanghai/Ningbo port

Industries We Service