Rotary Tiller Gearboxes – Replacement of Comer Code TB-19J

The Rotary Tiller Gearbox TB-19J, crafted by TEBSA in Argentina, is a vital component that channels power from a tractor’s PTO to the tines of a rotary tiller. Built for durability and precision, this gearbox ensures efficient soil preparation for farmers tackling crops like soybeans, wheat, or corn across Argentina’s fertile fields, such as the Pampas plains. Since 1997, TEBSA has delivered reliable agricultural gearboxes with a 100% quality guarantee, and the TB-19J stands as a testament to our expertise, offering a 50% cost advantage over original brands.

This gearbox features a sturdy housing, precision gears, high-grade bearings, and robust seals. When the tractor’s PTO spins the input shaft, the gears mesh seamlessly to transfer rotational force to the output shaft, driving the tiller’s blades with controlled speed and direction. Whether you’re breaking tough soil in Buenos Aires or prepping seedbeds in Córdoba, the TB-19J delivers consistent performance, making it a go-to choice for agricultural and landscaping tasks.

Technical Specifications of the TB-19J Rotary Tiller Gearbox

| Ratio (i) | 1.46 |

| Input Speed (N1) [rpm] | 540 |

| Power (P1) [kW] | 16.9 |

| Torque (M2) [Nm] | 423 |

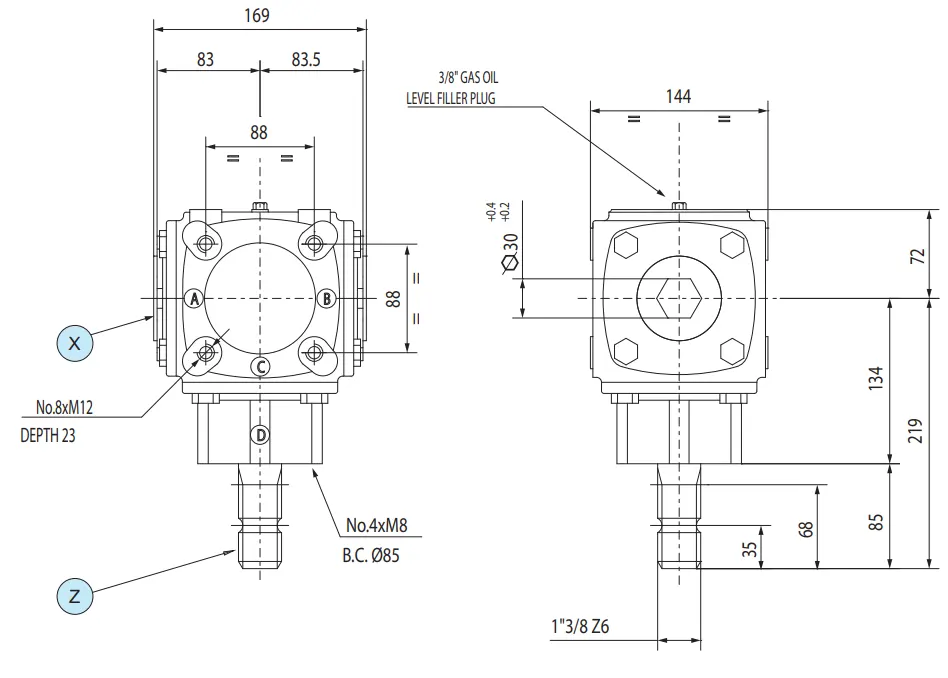

Shaft X  |

30 |

Shaft Z  |

1'' 3/8 Z6 |

| Input | Z |

Design and Performance Features

The TB-19J rotary tiller gearbox is engineered for farmers and landscapers who need reliable power transfer in demanding conditions. Its 1.46 gear ratio optimizes the balance between speed and torque, delivering 423 Nm of force to churn through hard-packed soil or clay with ease. The input speed of 540 rpm, standard for most tractors in Argentina, ensures compatibility with a wide range of equipment, from small farms in Rosario to large operations in Santa Fe.

Crafted with high-strength alloy steel, the gears undergo advanced processes like carburization and grinding to resist wear and maintain precision. The housing, made of cast iron, shields internal components from dust, debris, and impacts—common challenges in Argentina’s diverse terrains. Tapered roller bearings support smooth operation under heavy loads, while high-quality seals prevent oil leaks, ensuring long-term reliability.

The TB-19J’s compact design keeps weight at bay (details in the specs table), making it easier to mount on rotary tillers without sacrificing sturdiness. Its 16.9 kW power capacity suits medium-duty tillers used for seedbed preparation, weed control, or land leveling. For Argentine farmers growing soybeans or wheat, this gearbox delivers the precision needed to create uniform soil textures, boosting crop yields.

This gearbox also shines in versatility. The 1'' 3/8 Z6 output shaft fits most standard tiller blades, while the 30 mm Shaft X ensures a secure connection to the PTO. Whether you’re tilling for vineyards in Mendoza or pastures in La Pampa, the TB-19J adapts to your needs, offering dependable performance at a cost 50% lower than many competitors.

Applications and Benefits in Agriculture

The TB-19J rotary tiller gearbox finds its place in a variety of agricultural tasks, making it a favorite among Argentine farmers and global buyers searching for “rotary tiller gearbox for sale” or “reliable tiller gearbox in Argentina.” Its primary role is driving the tines of rotary tillers, which break up soil for planting, mix in fertilizers, or clear weeds. Here are key applications and advantages:

Seedbed Preparation: The TB-19J powers tillers to create fine, even soil beds, critical for high-value crops like corn or soybeans in Argentina’s grain belt.

Weed Management: Its precise control helps farmers till shallow depths to uproot weeds without disturbing deeper soil layers, ideal for organic farms.

Land Reclamation: In rugged areas like Patagonia, the gearbox tackles compacted or rocky soil to prep land for grazing or crops.

Vineyard and Orchard Care: In Mendoza’s wine country, it supports narrow tillers for inter-row cultivation, protecting delicate roots.

The benefits are clear. First, **efficiency**: The TB-19J transfers power with minimal loss, letting farmers cover more ground faster—crucial during tight planting seasons. Second, **durability**: Built with materials like alloy steel and cast iron, it withstands Argentina’s hot summers and dusty fields. Third, **safety**: TEBSA’s rigorous ISO9001-2015 standards ensure every unit is tested for flawless operation, reducing risks on the farm.

Cost savings are a big draw. At 50% less than original brands, the TB-19J offers “cheap rotary tiller gearbox” seekers a high-value option without cutting corners. Its easy maintenance—think accessible seals and straightforward oil checks—keeps downtime low, and our engineering team in Argentina responds within 24 hours to any questions, making TEBSA a trusted partner for buyers searching “rotary tiller gearbox supplier near me.”

Maintenance and Compatibility Tips

Keeping the TB-19J in top shape is straightforward, ensuring years of reliable use for farmers and landscapers. Regular maintenance starts with checking the oil level every 50 hours of operation, using manufacturer-approved gear oil to maintain the 0.95 L capacity. Inspect seals for wear to prevent leaks, especially after heavy tilling in dusty regions like Salta. Clean the input shaft (Shaft Z) and apply fresh grease to avoid friction damage.

Alignment matters. Ensure the gearbox and tiller are properly mounted to avoid uneven wear on gears or bearings. Every 500 hours, check for loose bolts or minor housing cracks, common after prolonged use on rocky soils. If you’re in Argentina’s humid areas, like Misiones, watch for corrosion and apply a protective coating to the housing as needed.

Compatibility is a strong suit. The TB-19J works with most 540 rpm PTO tractors, from compact models for small farms to mid-range ones for commercial operations. Its 1'' 3/8 Z6 shaft fits standard tiller blades, but always confirm your tiller’s specs before buying. For online buyers searching “buy rotary tiller gearbox online,” TEBSA offers clear specs and fast quotes to simplify the process.

Here’s a quick reference for maintenance tasks:

| Task | Frequency | Notes |

|---|---|---|

| Check Oil Level | Every 50 hours | Use approved gear oil |

| Inspect Seals | Every 100 hours | Replace if worn |

| Grease Input Shaft | Every 200 hours | Clean before applying |

| Check Housing/Bolts | Every 500 hours | Look for cracks or looseness |

This gearbox is a workhorse for “rotary tiller gearbox replacement” needs, offering a plug-and-play solution for worn-out units. Its robust design and TEBSA’s fast support make it a smart pick for Argentina’s farmers and beyond.

About TEBSA and Our Agricultural Solutions

Since 1997, TEBSA has been a cornerstone of agricultural innovation in Argentina, delivering high-performance gearboxes with a 100% quality guarantee. Based in the heart of Argentina’s farming region, we combine decades of expertise with cutting-edge manufacturing—think forging, heat treatment, and precision grinding—to produce equipment that lasts. Our ISO9001-2015 certification reflects our commitment to excellence, and our 50% cost advantage makes us a go-to for farmers searching “agricultural gearbox supplier in Argentina.”

Our engineering team responds within 24 hours, whether you’re in Buenos Aires or browsing “buy farm gearbox online” from abroad. Beyond the TB-19J, we offer a wide range of agricultural gearboxes, including:

Rotary Cutter Gearboxes: Like the RC-61, perfect for mowing pastures or clearing land.

Fertilizer Spreader Gearboxes: For precise nutrient distribution in soybean fields.

Post Hole Digger Gearboxes: Ideal for fencing or tree planting in Patagonia.

Flail Mower Gearboxes: Great for orchard maintenance in Mendoza.

PTO Shafts: Connect your tractor to any implement with ease.

From compact farms to sprawling estates, TEBSA’s solutions boost productivity while keeping costs down. Contact us today to explore how the TB-19J or our other products can power your next season.

About us

We guarantee top-quality products at the best prices in China! Special orders are welcome, and if you’re interested in any of our products, feel free to reach out for more detailed information. We ensure our products are safe, high-quality, and reasonably priced. Please contact us as soon as possible if you’d like to learn more. We’re eager to cooperate with you!

A large portion of our products is exported to Europe and the Americas, with both standard and custom options available. We can manufacture according to your drawings or samples, using standard materials or as per your specific requirements. Choosing us means choosing reliability.

Materials Available

1. Stainless Steel: SS201, SS303, SS304, SS316, SS416, SS420

2. Steel:C45(K1045), C46(K1046),C20

3. Brass:C36000 ( C26800), C37700 ( HPb59), C38500( HPb58), C27200(CuZn37), C28000(CuZn40)

4. Bronze: C51000, C52100, C54400, etc

5. Iron: 1213, 12L14,1215

6. Aluminum: Al6061, Al6063

7.OEM according to your request

Surface Treatment

Annealing, natural canonization, heat treatment, polishing, nickel plating, chrome plating, zinc plating,yellow passivization, gold passivization, satin, Black surface painted etc.

Processing Method

CNC machining, punch,turning, milling, drilling, grinding, broaching, welding and assembly

QC & Certificate

Technicians self-check in production,final-check before package by professional Quality inspector

ISO9001:2008 , ISO14001:2001,ISO/TS 16949:2009

Package & Lead Time

Size: Drawings

Wooden Case/Container and pallet, or as per customized specifications.

15-25days samples. 30-45days offcial order

Port: Shanghai/Ningbo port

Industries We Service