Flail Mower Gearboxes – Replacement of Comer Code L-5A 1:1.89

The Flail Mower Gearbox L-5A, crafted by TEBSA in Argentina, is a robust solution for powering flail mowers used in tough agricultural and landscaping tasks. Whether you're clearing overgrown pastures in the Pampas, maintaining orchards in Mendoza, or tackling roadside weeds in Buenos Aires, this gearbox delivers the strength and reliability you need. Since 1997, TEBSA has built a legacy of quality, offering a 100% guarantee on every order and cutting costs by up to 50% compared to original brands.

Designed for heavy-duty use, the L-5A transfers power from the engine to the flail mower’s rotating blades with precision. Its cast iron GG20 housing withstands the rigors of Argentina’s diverse terrains, while a 1:1.89 gear ratio ensures efficient performance. A built-in safety clutch protects the system by disengaging blades if the engine stalls or the operator eases off the throttle. Durable, affordable, and easy to maintain, the L-5A is a top choice for farmers, landscapers, and industrial users across Argentina.

Why Choose the L-5A Flail Mower Gearbox?

The L-5A stands out in the agricultural gearbox market for its blend of durability, efficiency, and cost-effectiveness. Here’s what makes it a go-to for flail mower users:

- Rugged Build: Made from cast iron GG20, it’s forged and heat-treated to endure heavy loads and harsh conditions, like Argentina’s dusty plains or humid farmlands.

- Efficient Power Transfer: The 1:1.89 gear ratio optimizes blade speed, making quick work of grass, weeds, or crop residue in soybean or wheat fields.

- Safety First: The integrated clutch prevents damage by stopping the blades during sudden stalls, keeping operators safe in demanding environments.

- Low Maintenance: Simple upkeep, with oil changes after 50-70 hours initially and every 500 hours thereafter, keeps it running smoothly.

- Cost Savings: TEBSA’s 50% cost advantage over original Comer gearboxes means you get premium performance without breaking the bank.

This gearbox suits a range of applications, from agricultural mowing to industrial band saws, making it versatile for Argentina’s farming and landscaping needs. Whether you’re a small-scale farmer or a large agribusiness, the L-5A delivers.

Technical Specifications of the L-5A Flail Mower Gearbox

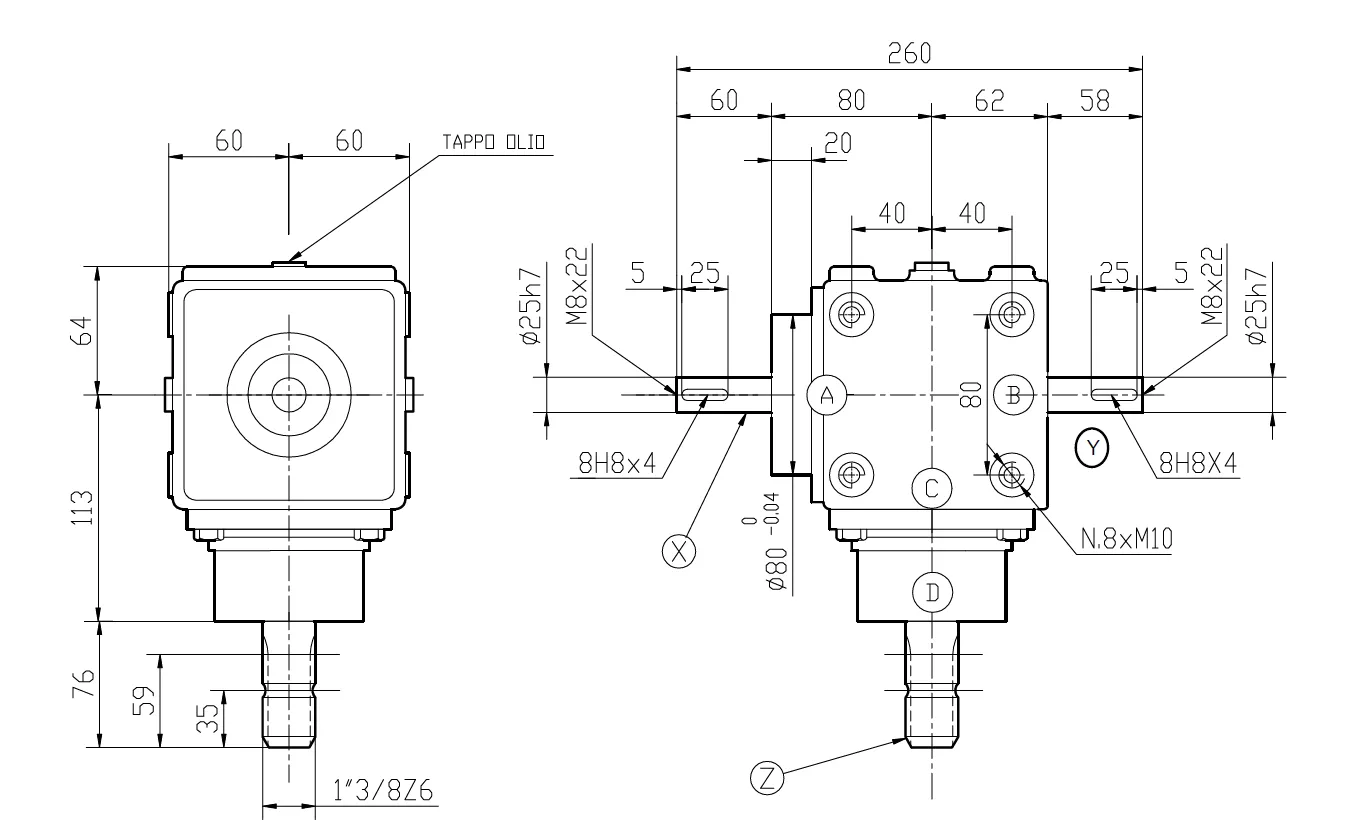

The L-5A is engineered for performance and durability. Below are its detailed specifications:

| Product Description |

Flail Mower Gearboxes - Replacement of Comer Gearbox L-5A 1:1.89

|

|---|---|

| Product details |

|

| Application range |

|

| Consists of |

|

| Max. output torque |

22.8 daNm

|

| Contains oil |

No

|

| Max. oil capacity |

0.4 l

|

| Max. oil change interval |

500 h

|

| Oil SAE viscosity grade |

80W-90

|

| Housing material |

Cast iron GG20

|

| Weight |

7.7 kg

|

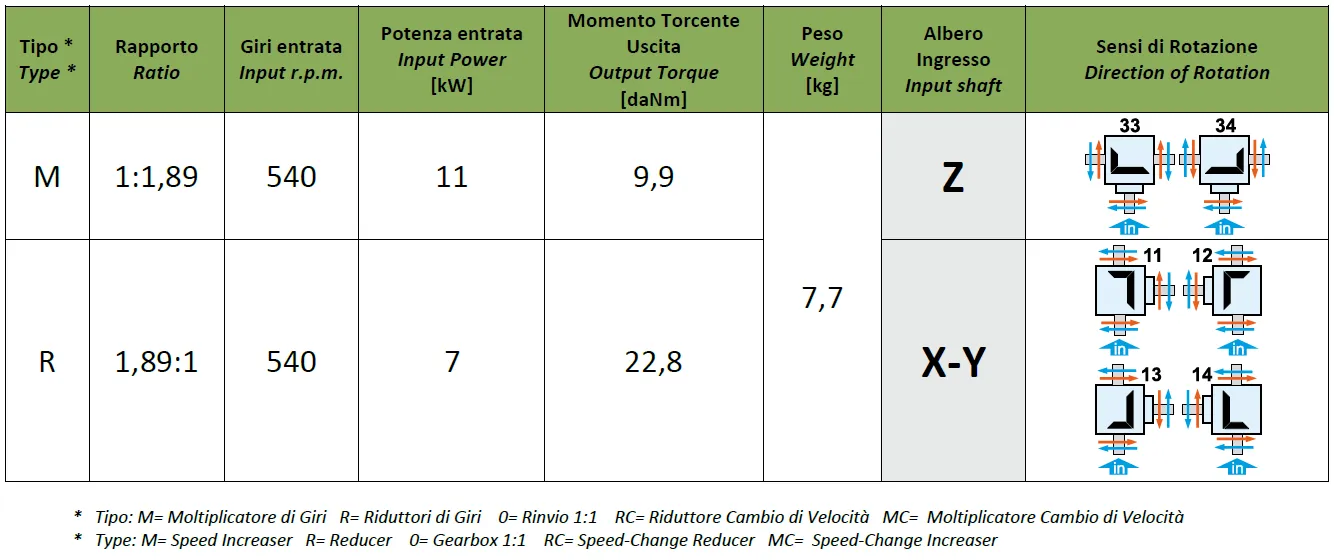

| Gear arrangement Increasing |

13 - 14

|

| Gear arrangement Reducing |

1 - 2

|

| Input power kW / HP Increasing |

11 / 15 kW/HP

|

| Input shaft Increasing |

X

|

| Input shaft Reducing |

Z

|

| Input power KW / HP Reducing |

7 / 9.5 kW/HP

|

| Output Torque DaNm Increasing |

9.9 daNm

|

| Ratio Increasing |

1: 1.89

|

| Ratio Reducing |

1.89: 1

|

| Shaft X |

25 (M)

|

| Shaft Z |

25 (D)

|

Applications and Benefits in Argentine Agriculture

The L-5A flail mower gearbox is a versatile workhorse, tailored to meet the demands of Argentina’s agricultural and landscaping sectors. Its ability to handle tough tasks makes it a favorite among farmers and contractors. Here’s how it shines:

- Agricultural Mowing: Perfect for clearing crop residue in soybean or corn fields, the L-5A powers through dense vegetation with ease, ensuring fields in Córdoba or Santa Fe are ready for planting.

- Pasture Management: In the Pampas, where grazing lands need regular upkeep, this gearbox keeps flail mowers running smoothly to maintain healthy pastures for cattle.

- Landscaping and Roadside Maintenance: From orchards in Mendoza to roadside verges in Buenos Aires, the L-5A tackles overgrown grass and weeds, keeping landscapes tidy.

- Industrial Uses: Beyond farming, it supports band saws and other equipment, offering flexibility for industrial tasks in Argentina’s growing agribusiness sector.

The L-5A’s benefits extend beyond its applications. Its cast iron GG20 construction, forged and heat-treated (via carburization), ensures it can handle the vibrations and shocks of heavy use. The 22.8 daNm maximum output torque delivers consistent power, while the 1:1.89 gear ratio balances speed and force for optimal cutting. The safety clutch adds a layer of protection, reducing downtime and repair costs. At just 7.7 kg, it’s lightweight yet sturdy, making it easy to install on various mower models.

For Argentine farmers, the L-5A’s 50% cost advantage over Comer gearboxes is a game-changer. It delivers high-end performance at a fraction of the price, backed by TEBSA’s ISO9001-2015 certification and 24-hour technical support. Whether you’re buying a flail mower gearbox online or equipping a fleet of mowers, the L-5A is a reliable, budget-friendly choice.

Maintenance and Installation Tips

To keep the L-5A flail mower gearbox performing at its best, follow these practical steps:

1. Initial Setup: The gearbox ships without oil. Fill it with 0.4 liters of 80W-90 oil before use to ensure smooth operation.

2. Oil Changes: Change the oil after 50-70 hours of initial use, then every 500-700 hours or annually. Check for contaminants to maintain performance.

3. Regular Inspections: Look for leaks, wear, or loose bolts, especially after heavy use in dusty or muddy conditions like Argentina’s rainy seasons.

4. Clutch Care: Test the safety clutch periodically to confirm it disengages properly, protecting both the gearbox and mower.

5. Alignment: Ensure the gearbox is properly aligned with the PTO shaft to avoid undue stress on gears.

For installation, the L-5A’s 25 mm shafts (X and Z) fit most standard flail mowers. Its compact design (gear arrangements 13-14 increasing, 1-2 reducing) simplifies mounting. If you need custom RPM settings, TEBSA’s engineering team can assist within 24 hours.

Below is a quick reference for maintenance intervals:

| Task | Frequency | Details |

|---|---|---|

| Initial Oil Fill | Before first use | 0.4 L, 80W-90 oil |

| First Oil Change | 50-70 hours | Replace with fresh oil |

| Regular Oil Change | 500-700 hours or yearly | Check for contaminants |

| Inspect Clutch | Monthly | Ensure proper disengagement |

By following these steps, you’ll extend the L-5A’s lifespan, keeping your flail mower ready for Argentina’s demanding agricultural tasks.

TEBSA: Your Trusted Partner in Agricultural Gearboxes

Since 1997, TEBSA has been a leading name in Argentina’s agricultural machinery sector, delivering high-quality gearboxes and components with a 100% quality guarantee. Based in Argentina, we combine advanced manufacturing—forging, casting, and precision machining—with a 50% cost advantage over original brands. Our ISO9001-2015 certification reflects our commitment to excellence, while our engineering team responds to inquiries within 24 hours, ensuring seamless support for farmers and businesses.

The L-5A flail mower gearbox is just one of our many solutions. We also offer a wide range of agricultural gearboxes, including:

- Rotary Cutter Gearboxes: Like the RC-61, ideal for heavy-duty cutting in soybean or wheat fields.

- Fertilizer Spreader Gearboxes: For precise nutrient distribution in Argentina’s fertile lands.

- Rotary Tiller Gearboxes: Built for soil preparation in corn or sunflower plantations.

- Post Hole Digger Gearboxes: Perfect for fencing or vineyard setups in Mendoza.

- PTO Shafts: Durable power transfer solutions for various farm implements.

Whether you’re managing a small farm or a large agribusiness, TEBSA’s products are designed to boost efficiency and reduce costs. Ready to buy a flail mower gearbox online or explore our catalog? Contact us today to see how we can power your operations in Argentina.

About us

We guarantee top-quality products at the best prices in China! Special orders are welcome, and if you’re interested in any of our products, feel free to reach out for more detailed information. We ensure our products are safe, high-quality, and reasonably priced. Please contact us as soon as possible if you’d like to learn more. We’re eager to cooperate with you!

A large portion of our products is exported to Europe and the Americas, with both standard and custom options available. We can manufacture according to your drawings or samples, using standard materials or as per your specific requirements. Choosing us means choosing reliability.

Materials Available

1. Stainless Steel: SS201, SS303, SS304, SS316, SS416, SS420

2. Steel:C45(K1045), C46(K1046),C20

3. Brass:C36000 ( C26800), C37700 ( HPb59), C38500( HPb58), C27200(CuZn37), C28000(CuZn40)

4. Bronze: C51000, C52100, C54400, etc

5. Iron: 1213, 12L14,1215

6. Aluminum: Al6061, Al6063

7.OEM according to your request

Surface Treatment

Annealing, natural canonization, heat treatment, polishing, nickel plating, chrome plating, zinc plating,yellow passivization, gold passivization, satin, Black surface painted etc.

Processing Method

CNC machining, punch,turning, milling, drilling, grinding, broaching, welding and assembly

QC & Certificate

Technicians self-check in production,final-check before package by professional Quality inspector

ISO9001:2008 , ISO14001:2001,ISO/TS 16949:2009

Package & Lead Time

Size: Drawings

Wooden Case/Container and pallet, or as per customized specifications.

15-25days samples. 30-45days offcial order

Port: Shanghai/Ningbo port

Industries We Service