Introduction to High-Speed Universal Joint Shaft Couplings

The High-Speed Universal Joint Shaft Couplings—especially the SWC-Bh Type—are the kind of gear that keeps the wheels turning in all sorts of machines, from air compressors to heavy-duty industrial setups. They’re like the quiet MVPs behind the scenes, making sure power gets where it needs to go without a fuss. Without these couplings, you’d have engineers scratching their heads and production lines grinding to a halt—nobody wants that!

Key Features of SWC-Bh Type Couplings

These couplings are built with an eye for detail, tough enough to last and slick enough to keep things running smooth. They’re designed to slot right into high-speed systems like they were born for it—think of them as the gears in a finely tuned engine, keeping the power flowing steady and strong. In the industrial world, they’re a must-have to dodge those pesky breakdowns.

Applications of Universal Joint Shaft Couplings

These couplings aren’t just handy—they’re everywhere you need them. Check out where they shine:

- Automotive machinery

- Agricultural equipment

- Mining machinery

- Textile manufacturing

- Packaging machines

- Small diesel engines

SPC Cast Iron V-Belt Pulleys

The SPC cast iron V-belt pulleys are a big deal when it comes to moving power around. Built to tough global standards, they’re not just dependable—they’re top performers in all kinds of setups. Picture a relay team passing the baton without a stumble; that’s these pulleys keeping your machines in sync.

Benefits of Using SPC Cast Iron V-Belt Pulleys

Here’s why these pulleys are worth a look:

- Power transmission over long stretches, no sweat

- Easy to pop off and fix up

- Fits all sorts of gear

- Big bang for your buck across the board

Cost-Effectiveness and Quality Assurance

When every dollar matters, SPC cast iron V-belt pulleys hit the sweet spot—great prices without cutting corners on quality. For anyone looking to keep things humming without breaking the bank, they’re a no-brainer. It’s like upgrading your kitchen gear to speed up service without spending a fortune.

Expanding Our Product Range

Besides our killer couplings and pulleys, we’ve got a whole lineup of industrial gear to brag about:

- Agricultural gearboxes

- Power output shafts

- Sprockets

- Hydraulic couplings

- Worm gear reducers

- Racks and roller chains

- Planetary gearboxes

- Timing pulleys and bushings

We’re all in on delivering top-shelf stuff at fair prices, with service that’s got your back. Got a custom idea? Send us your sketches or samples—we’ll tailor it to fit just right, like a suit made just for you.

Frequently Asked Questions

1. What’s the SWC-Bh Type coupling good for?

It’s a champ in automotive, farming, and manufacturing gear—think of it as the pulse keeping those machines alive.

2. How do SPC V-belt pulleys boost my setup?

They keep power steady, make fixes a breeze, and play nice with all kinds of systems—like the backbone you didn’t know you needed.

3. Can I tweak your products to my specs?

You bet! Share your drawings or samples, and we’ll whip up something custom just for you.

4. Why pick your stuff over the other guys?

Quality that lasts, prices that don’t sting, and service you can lean on—like having a buddy who knows his way around a toolbox.

5. Are these good for high-speed jobs?

Absolutely—they’re built to handle the fast lane and keep things running smooth as silk.

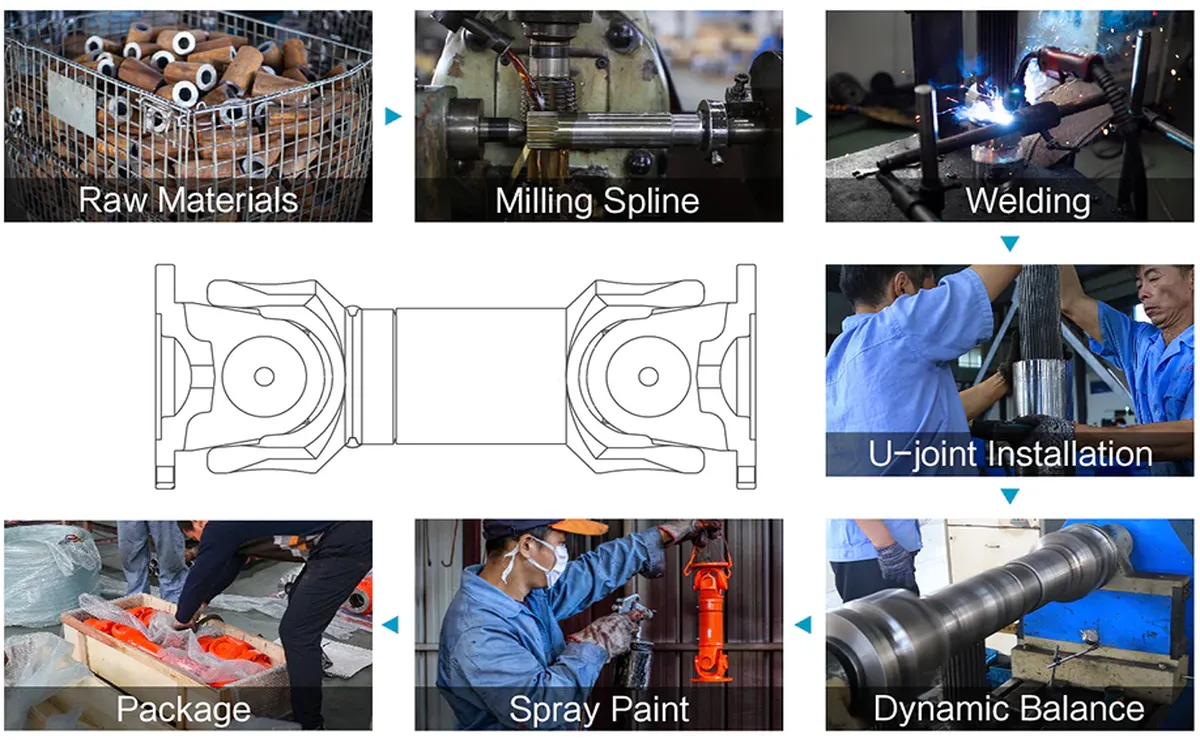

Performance Characteristics of Cardan Shaft

Cardan shafts—aka universal joint shafts—are the heavy lifters in all sorts of setups. Here’s what makes them tick:

- Bend, Don’t Break: They pass torque even when things aren’t lined up perfect—like a dancer nailing a tricky spin.

- Tough Stuff: Made from rugged materials, they shrug off wear and keep going strong—built for the long haul.

- Power Flow: They move energy with next to no loss—like a car that stretches every drop of gas.

Types and Characteristics of Cardan Shaft

Cardan shafts come in a few flavors—picking the right one’s like grabbing the perfect tool:

- Single Cardan Shaft: Simple and solid, great for jobs with little wiggle room.

- Double Cardan Shaft: Two joints for extra flex—think vehicles and gear that need to twist and turn.

- Telescopic Cardan Shaft: Stretches or shrinks to fit—perfect when distances shift on the fly.

Materials matter too—steel’s your powerhouse, aluminum keeps it light, and composites fight rust like champs. Each one’s got its own edge depending on the gig.

Applications of Cardan Shaft

These shafts show up all over—here’s where they make a difference:

- Automotive Industry: Linking transmissions to wheels—like a racecar nailing every curve.

- Industrial Machinery: Powering conveyors and mixers—holding it all together like glue.

- Marine Industry: Keeping boat props spinning—steady as she goes, even in choppy waters.

- Railway Systems: Moving power from engines to cars—smooth rides start here.

- Farming Equipment: Connecting engines to tools—feeding the world, one field at a time.

Future Development Trends and Opportunities of Cardan Shaft

Cardan shafts have a big future ahead—think lighter materials like composites cutting weight and boosting efficiency, like swapping a heavy coat for a sleek jacket. Automation’s on the rise too, and these shafts will need to step up for precision in high-tech setups. Companies that dig into R&D are gonna lead the pack as things heat up.

Choosing a Suitable Cardan Shaft

Getting the right Cardan shaft takes some thought—here’s your playbook:

- Know Your Gig: Figure out what your setup needs—machine type, conditions, all that jazz.

- Power Check: Match torque and load so it doesn’t buckle—like sizing up a bridge before crossing.

- Length Game: Measure right, and decide if you need stretch—telescopic’s your friend if things move.

- Joint Call: Pick the U-joint type based on how much twist you’re dealing with.

- Material Pick: Steel for strength, aluminum for light, or composites for rust-proof—match the vibe.

- Weather It: Think heat, wet, or chemicals—make sure it can take the hit.

Conclusion

Cardan shafts are the unsung heroes keeping industries rolling, with flex, grit, and smarts to spare. Knowing their types, uses, and material perks helps you pick the winner for your setup. As tech keeps moving, these shafts will too—staying sharp for whatever’s next. Nail the right one, and you’re set for smooth sailing and long runs.

Author: Dream

All this stuff’s pulled from the web—just a heads-up for picking parts. Our gear’s replacement stuff, not the original deal—we don’t own the trademarks. It’s built for aftermarket fixes and fits the originals like a glove. Want the real thing? Hit up the original maker or supplier.