In the world of agriculture, where machinery works tirelessly across fields and seasons, every component matters. From the gearbox powering a tractor to the pump driving irrigation, the smallest parts play a big role in keeping operations running smoothly. Among these, jaw couplings have carved out a niche as a dependable choice for connecting shafts and transferring power. But are they the right fit for your equipment? To answer that, let’s dive deep into the advantages and disadvantages of jaw couplings, exploring how they perform in the rugged, unpredictable environment of farming.

Understanding Jaw Couplings: A Quick Rundown

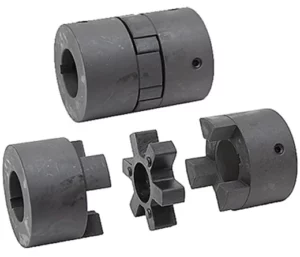

Before we get into the pros and cons, it’s worth understanding what a jaw coupling actually is. Picture two metal hubs, each with interlocking “jaws,” sandwiching a flexible insert—usually a star-shaped piece called a spider, made of rubber or polyurethane. This setup allows the coupling to transmit torque from one shaft to another while compensating for slight misalignments or vibrations. In agricultural settings, you might find jaw couplings linking a motor to a gearbox on a conveyor, a pump, or even a small tractor. Their simplicity and adaptability make them a staple—but they’re not flawless. Let’s break it down.

The Upside: Why Farmers Choose Jaw Couplings

Jaw couplings have a loyal following for good reason. They bring a handful of practical benefits to the table, especially for agricultural machinery where reliability and cost often go hand in hand. Here’s what makes them stand out:

- Handling Misalignment Like a Pro

Farm equipment rarely operates on perfectly level ground. Tractors bounce over rocky soil, and pumps shift slightly as pipes settle. Jaw couplings are built to handle this chaos. They can tolerate angular misalignment (up to a degree or two), parallel misalignment (a few millimeters), and even slight axial movement. This flexibility means less strain on your gearbox or motor, reducing the risk of premature wear. For instance, imagine a farmer running a PTO-driven mower: a jaw coupling can keep things humming even if the shafts aren’t perfectly aligned after a bumpy ride. - Smoothing Out the Rough Stuff

Vibration is the enemy of machinery longevity. Sudden jolts—like when a tractor hits a hidden stump—can send shockwaves through the system. The spider in a jaw coupling acts like a cushion, soaking up those vibrations and softening the blow. This dampening effect protects delicate components, such as bearings or seals in a gearbox, making it a lifesaver during the high-stakes harvest season when downtime isn’t an option. - A Breeze to Install and Fix

Time is money on a farm, and jaw couplings respect that. Installing one doesn’t require a toolbox full of specialized gear—just line up the hubs, slide in the spider, and tighten it down. If the spider wears out (more on that later), you can swap it out without dismantling the whole setup. Picture a busy mechanic in the middle of planting season: a quick spider replacement gets the equipment back in action fast, no fuss required. - Wallet-Friendly Performance

Farming is a business of tight margins, and jaw couplings deliver solid value. They’re less expensive than heavy-duty alternatives like gear couplings or fluid couplings, yet they hold their own in moderate-duty tasks. For a small farm upgrading a water pump or a conveyor system, this affordability can free up budget for other priorities—like seed or fuel. - No Grease, No Mess

Some couplings demand regular lubrication to stay in top shape, but not jaw couplings. The spider does the heavy lifting without needing a drop of oil. In dusty, gritty farm environments, this is a huge plus—there’s no grease to attract dirt or clog up the works. It’s one less chore on an already long list.

The Downside: Where Jaw Couplings Fall Short

As handy as jaw couplings are, they’re not perfect for every situation. Knowing their limitations can save you headaches down the road. Here’s where they might let you down:

- Torque Limits Can Trip You Up

Jaw couplings are champs for light to medium loads, but they hit a ceiling when it comes to torque. If you’re running a massive combine harvester or a high-powered tiller, the coupling might buckle under the strain. The spider, while flexible, can only handle so much before it deforms or fails. For heavy-duty jobs, you might need to step up to a sturdier option like a disc coupling or even a chain coupling. - The Spider’s Achilles’ Heel

That trusty spider? It’s a double-edged sword. While it absorbs shocks, it’s also the part most likely to wear out. Heat from friction, cold snaps in winter, or relentless UV rays beating down on outdoor equipment can degrade the material over time. A farmer in Argentina, for example, might notice the rubber spider cracking after months of intense heat and dust. When it goes, you’ll feel it—vibration spikes, noise increases, and eventually, the coupling could fail altogether if you don’t catch it in time. - Speed Bumps at High RPMs

Spin a jaw coupling too fast, and things get dicey. The spider’s flexibility, great for dampening, becomes a liability at high speeds. It can’t keep up, leading to wobble or heat buildup that wears it out faster. If your irrigation pump runs at a modest pace, no problem—but for a high-RPM motor driving a grain auger, you might need something more rigid. - A Touch of Backlash

Backlash—the slight play between components—can sneak into standard jaw couplings. While some designs use preloaded spiders to minimize this, it’s still a factor. In precision tasks, like syncing a conveyor belt to a motor, that tiny lag might throw things off. It’s not a dealbreaker for most farm uses, but it’s worth noting if accuracy is non-negotiable. - Not Built for Extreme Conditions

Harsh weather can test any coupling, and jaw couplings aren’t the toughest contenders. Freezing temperatures might stiffen the spider, while scorching heat can soften it. In coastal areas with salty air, corrosion could nibble at the metal hubs. They’ll do fine in moderate climates, but extreme environments might call for a hardier alternative.

Real-World Scenarios: When to Use Jaw Couplings

So, where do jaw couplings fit in agriculture? They’re a natural match for smaller tractors linking a PTO to a mower or a pump driving a modest irrigation system. Take a 50-horsepower tractor as an example: a jaw coupling can smoothly connect the engine to the gearbox, handling bumps and jolts without breaking the bank. But if you’re powering a 200-horsepower beast tearing through dense soil, the torque might overwhelm it—time to look elsewhere.

They also shine in setups where maintenance needs to be quick and painless. A farmer with a tight schedule can keep a few spare spiders on hand, swapping them out in minutes. Contrast that with a gear coupling, which might demand hours of greasing and alignment—not ideal when crops are waiting.

Tips for Getting the Most Out of Jaw Couplings

Want to maximize their strengths and sidestep the pitfalls? Here’s some practical advice:

- Check the Spider Regularly: Pop the hood every few months to inspect for cracks or wear. A $10 replacement beats a $500 gearbox repair.

- Match the Load: Size the coupling to your equipment’s torque and speed. Manufacturer specs (like those from Tebsa) can guide you.

- Shield from the Elements: If possible, house the coupling in a cover to fend off sun, rain, or dust.

- Upgrade the Spider: For tougher jobs, opt for a polyurethane spider over rubber—it’s more durable and heat-resistant.

Why Source from a Trusted Manufacturer?

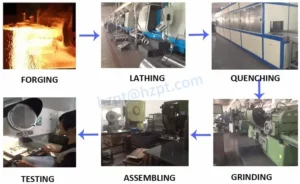

The quality of your jaw coupling depends heavily on who makes it. That’s where Tebsa, an Argentinian company with deep roots in the industry, steps in. Since kicking off in 1997, Tebsa has built a reputation as a professional, experienced manufacturer, delivering mechanical components with a 100% quality guarantee. Their variety mechanical capability spans fast prototypes to full-scale production, perfect for customizing couplings to your farm’s needs. With competitive strategic marketing, they offer products at 50% the cost of original brands, and their talented engineering team responds within 24 hours, ensuring smooth collaboration.

Wrapping It Up: Are Jaw Couplings Right for You?

Jaw couplings bring a lot to the table—misalignment tolerance, vibration control, and a price tag that won’t scare you off. They’re a farmer’s friend for moderate-duty tasks where simplicity and savings matter. But they’re not invincible. Torque limits, spider wear, and speed constraints mean they’re not the answer for every job. By weighing the advantages and disadvantages of jaw couplings, you can zero in on what your machinery really needs.

Looking to equip your farm with top-notch jaw couplings? Tebsa has your back. With over two decades of expertise and a knack for affordable, reliable solutions, they’re ready to help. Drop by their site or reach out—their smart team will get back to you in a day, guaranteed.

What are the main advantages of jaw couplings for farm equipment?

Jaw couplings offer several benefits that make them popular in agriculture. They handle misalignment well—think angular, parallel, or axial shifts—which is handy when machinery operates on uneven fields. They also dampen vibrations, protecting gearboxes and motors from wear, and they’re easy to install or repair, saving time during busy seasons. Plus, they’re cost-effective and don’t need lubrication, a big win for dusty farm environments. These perks make them a practical choice for moderate-duty tasks like powering small tractors or pumps.

What disadvantages should I watch out for with jaw couplings?

While jaw couplings have their strengths, they’re not perfect. They struggle with high torque, so they might not suit heavy machinery like large harvesters. The spider—the flexible part—wears out over time, especially in harsh weather, and needs regular checks. They’re also less effective at high speeds, where the spider can’t keep up, and they might introduce slight backlash, affecting precision. Knowing these limits helps you decide if they fit your setup.

How often should I replace the spider in a jaw coupling?

It depends on your usage and conditions. In typical farm settings—say, a tractor running a few hours daily—a rubber spider might last 6-12 months. But if you’re in a hot, dusty area or pushing the coupling hard, it could wear out faster, maybe every 3-6 months. Check it every few months for cracks, softness, or brittleness. Swapping it out early is cheap insurance against bigger breakdowns. For tougher jobs, a polyurethane spider might last longer.

Can jaw couplings handle the demands of heavy-duty agricultural machinery?

Not always. Jaw couplings shine in light to medium loads—think a 50-horsepower tractor or a small irrigation pump. But for heavy-duty gear, like a 200-horsepower combine chewing through thick crops, they might not cut it. Their torque capacity tops out, and the spider can fail under extreme stress. If your equipment demands serious power, consider a gear or disc coupling instead. Match the coupling to your machine’s specs to avoid trouble.

How do I know if a jaw coupling is the right choice for my gearbox?

Start by assessing your needs. If your gearbox powers a modest load, runs at moderate speeds, and faces some misalignment—like a conveyor or PTO-driven mower—a jaw coupling could be ideal. Its advantages (cost, ease, vibration control) outweigh the disadvantages for such tasks. But if you need high torque, precision, or durability in extreme conditions, look elsewhere. A trusted supplier like Tebsa can help you pick the perfect fit—reach out to their team for expert advice tailored to your farm.