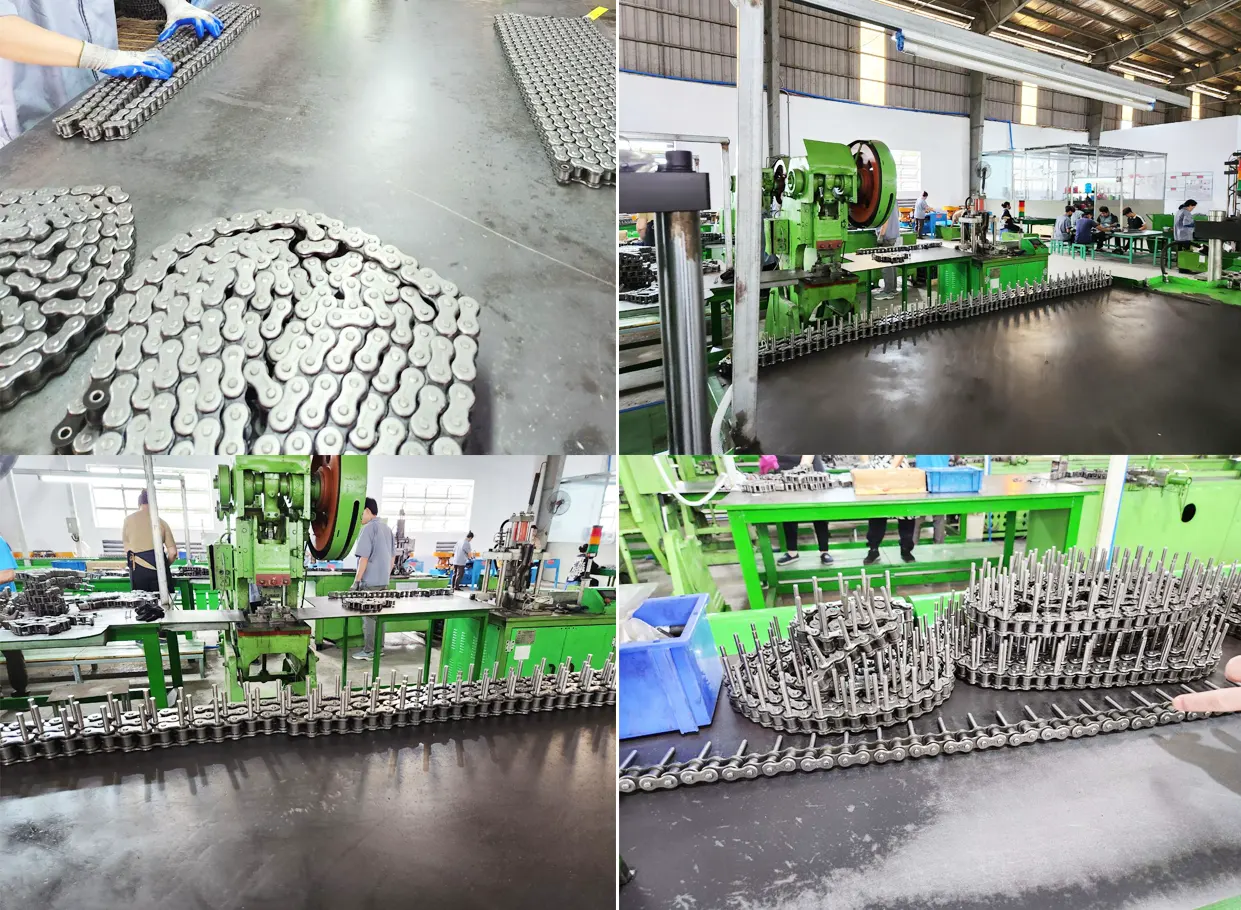

Unleash Power with Premium Roller Chains

Dive into our world of roller chains, where strength meets precision. Designed specifically for heavy-duty motorcycle transmissions and a variety of automotive needs, these chains are forged from top-tier stainless steel. Built to withstand tough conditions, they’re not just for bikes—our roller chains also power industrial machinery, boosting performance and efficiency wherever they’re used.

What Makes Our Roller Chains Stand Out?

Our roller chains feature a smart short-pitch design, perfect for complex transmission setups. They’re tough yet surprisingly lightweight, which means less strain on your equipment over time. With precision at the heart of our engineering process, these chains deliver seamless operation and help your machines last longer.

Where Our Roller Chains Shine

Versatility is the name of the game. Our roller chains are trusted across a range of industries, including:

- Automobile Manufacturing

- Textile Industry

- Agricultural Machinery

- Food Processing

- Pharmaceuticals

Built to Last, Designed to Perform

Made from high-quality stainless steel, our roller chains laugh in the face of corrosion and wear. They’re built to keep going strong, making them a smart choice for any operation that values reliability over the long haul.

Beyond Roller Chains: Our Full Lineup

We don’t stop at roller chains. Our catalog is packed with industrial essentials like:

- Agricultural Gearboxes

- Power Output Shafts

- Sprockets

- Hydraulic Couplings

- Worm Gear Reducers

- Racks

- Pulleys

- Planetary Gearboxes

- Timing Pulleys

- Bushings

Every item we produce meets rigorous quality standards, delivering unbeatable value. Got a unique project? We’re happy to customize based on your drawings or samples to fit your exact needs.

Your Questions, Answered

1. What’s inside our roller chains?

We craft them from premium stainless steel, ensuring they’re tough and corrosion-resistant.

2. Can I tweak my order?

Absolutely! Send us your drawings or samples, and we’ll tailor the product to your specs.

3. Who do we work with?

We support industries like automotive, textiles, agriculture, food processing, and pharmaceuticals—just to name a few.

4. How do payments work?

We ask for a 30% deposit upfront, with the rest due against documents. Options like Western Union and L/C at sight are also on the table.

5. How fast can I get my order?

Typically, it’s 35 days from confirmation, but we can speed things up during quieter seasons.

Why Gear Chains Matter

Gear chains are the unsung heroes of machinery, driving performance in countless setups. Here’s what sets them apart:

- Efficiency: They keep energy loss low, a must for power-hungry systems.

- Durability: Built tough, they handle heavy loads without breaking a sweat.

- Quiet Operation: Some designs cut noise, perfect for sound-sensitive spaces.

- Strength: They’re ready for big jobs across industries.

- Flexibility: From cars to factories, they adapt to almost anything.

Exploring Gear Chain Types

Not all gear chains are the same. Here’s a rundown of the main types:

- Roller Chains: Simple, reliable, and great for long-distance power transfer.

- Silent Chains: Quiet runners for noise-sensitive tasks.

- Inverted Tooth Chains: Smooth and fast, ideal for high-speed work.

- Block Chains: Heavy-duty champs for big machinery.

Material Matters in Gear Chains

The stuff they’re made of changes the game:

- Steel: Strong and steady for the toughest jobs.

- Stainless Steel: Corrosion-proof for harsh settings like food production.

- Plastic: Light and chemical-resistant for specialized uses.

Where Gear Chains Make a Difference

These chains pop up everywhere, proving their worth:

- Automotive: Keeping engines ticking smoothly.

- Industry: Powering conveyors and robots.

- Heavy Duty: Lifting loads in cranes and excavators.

- Aviation: Timing engines with precision.

- Farming: Running tractors and harvesters.

What’s Next for Gear Chains?

The future looks bright:

- Smart Tech: Think chains that monitor themselves.

- New Materials: Lighter, stronger options on the horizon.

- Custom Fits: More tailored designs for specific needs.

Picking the Perfect Gear Chain

Here’s how to nail your choice:

- Know Your Needs: Match the chain to your machine’s demands.

- Pick a Type: Find the right fit for your job.

- Choose Wisely: Factor in environment and wear.

- Maintenance Check: Plan for upkeep costs.

- Fit Matters: Ensure it works with your setup.

- Weigh Costs: Balance price and performance.

Wrapping It Up

Gear chains are the backbone of countless machines, driving efficiency and power across industries. Knowing their types, materials, and uses helps you pick the best one for the job—and keep things running smoothly for years.

All content here comes from online sources and is for reference only. Our products are replacement parts, not originals, and we don’t own the trademarks. They’re designed for aftermarket use, fitting perfectly with original parts. For originals, reach out to the manufacturer or supplier directly.

Author: Dream